When Crave started out in 2011, its co-founders knew there would be a certain amount of stigma to overcome around the company’s products.

Sex toys, after all, grew out of the 1960s porn industry and there is still a lingering embarrassment around their purchase and use. So Michael Topolovac and Ti Chang knew that if they asked women if they’d be prepared to wear a vibrator out in public, hanging from a necklace, their interviewees might either recoil in horror or laugh in their faces.

There were other problems to overcome, too, says Topolovac. “When I first had the idea for Crave, it struck me that these products are very male-dominated, both in terms of who was designing them and the nature of the product itself,” he says.

“By applying good design through understanding the user and the quality experience they are looking for, you can create design-focused products, rather than approaching it like a novelty item, where a dolphin or bunny rabbit meets a penis.”

It’s this thoughtful approach that has enabled Crave to go on to launch its vibrator necklace, the Vesper, which has not only been its best-selling product to date, but also racked up a stack of design awards.

More like a piece of jewellery than something you’d hide in the back of a bedside drawer, the sleek, brushed stainless steel, 9.65cm pendant-cum-vibrator hangs from a delicate chain around its wearer’s neck. Of course, users can keep this USB rechargeable device in a drawer at home if they like, but as a necklace, it serves as a conversation starter, fulfilling Crave’s mission of encouraging conversations about sexuality and desire.

“I wanted to create a gorgeous object that functions equally well as a vibrator and as jewellery, with no compromises. People should be able to own their pleasure, in private and public,” says Ti Chang, Crave’s co-founder and lead designer.

Craving a change

But how did a seasoned entrepreneur with a background in PLM cloud computing (Topolovac) and a skilled industrial designer (Chang) come together to reimagine sex toys?

Chang, whose family immigrated from Taiwan to the US when she was six years old, knew nothing about industrial design until she found herself majoring in the subject at college. With a scholarship to Georgia Tech, she knew she didn’t want to major in engineering, so her choice was between architecture and industrial design.

She chose the latter and has never looked back. She went on to complete her Masters degree at the Royal College of Art in London on the Design Products programme.

During her career, Chang has designed a variety of products, from hairbrushes to furniture. At Trek, a US bicycle manufacturer, she was the company’s first industrial designer.

“I was working on a team of ten guys and on my first day, they realised they didn’t have a women’s bathroom for me. So they had to find a small closet, clean it out and immediately build one. They all ended up using my toilet anyway, because it was nicer,” she laughs.

But, as the years went on, Chang realised that her real passion lay in designing better consumer products for women.

The catalyst that sent her down the path of designing sex toys came in about 2008, when she stepped inside a sex shop. It wasn’t her first time inside one, she says, but this time, as she stood aghast looking at the wall of items in front of her, she suddenly recognised the huge disconnect that lies between what women want from these intimate products and what is actually on offer to them.

“It dawned on me that women shouldn’t have to put up with crappy sex toys and, as a trained industrial designer, I decided that I could create much more sophisticated and well-considered products that are geared towards women.

So I set up a company called Incoqnito to do just that,” she says.

From cloud to Crave

In the meantime, Topolovac had graduated in product design from Stanford University and started Light & Motion Industries (LMI), a manufacturer of underwater video, photo and bike lighting products.

“It was a bootstrapped venture,” he explains. “I lived on ramen noodles and off credit cards, but I learnt a lot during that time as we built everything ourselves in our factory in California.”

As the range grew, the company was using spreadsheets to manage complex products, each containing between 2,000 to 3,000 parts and involving global supply chains.

It was primarily out of frustration, then, that Topolovac ended up building a PLM [product lifecycle management] tool to run LMI. The solution was later spun out as a separate company, shifted to the cloud, and the start-up eventually became known as Arena Solutions. Says Topolovac: “Spending the next eight years in enterprise software, I learnt a lot about building larger companies, as we managed to raise $45 million in funding.

I also learnt how you evangelise a category, because early on, PLM wasn’t a thing and cloud computing was very nascent. Now, it’s what everybody does.” In 2008, he left to set up Crave, although the idea for the company dawned on him some years before, over dinner with a couple of female friends. The topic of sex toys came up and his friends told him how terribly designed these products were and how buying them involved visits to seedy shops in dark alleyways.

“I saw it as a really big business opportunity, giving an underserved market the attention it deserved. As an entrepreneur with experience of building two successful companies, I was able to raise a decent amount of capital to set up Crave, but felt from day one that it needed a strong female voice – certainly on the design side – to lead the brand,” he says.

It was at a trade show where Topolovac was conducting market research that he bumped into Chang. It didn’t take long for the two to realise that this was a rather fortuitous encounter and that they should join forces.

To get Chang onboard as co-founder of Crave, Topolovac essentially had to buy her company Incoqnito. This was in 2011, and the pair immediately set up shop at an office in San Francisco and began designing the company’s flagship product, the Duet.

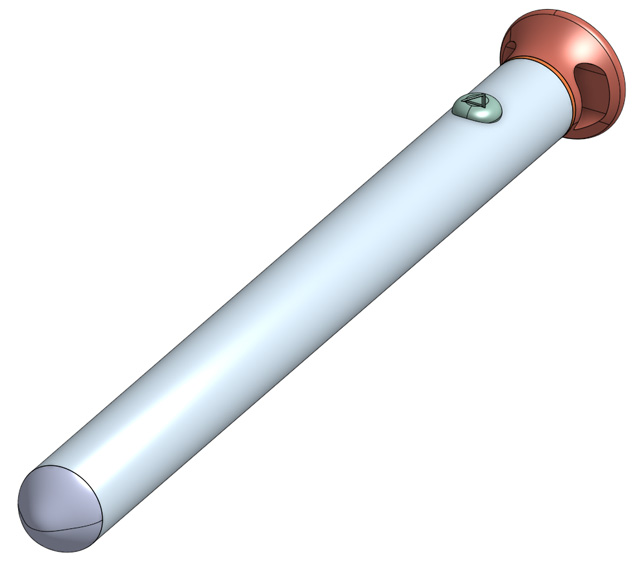

A discreet design with a silicone vibrating tip, the first version of Duet came with a USB memory drive and optional 24-karat gold plating. To fund its production, Crave launched a crowdfunding campaign and secured over $100,000, representing 694% of the original target. The Duet thus became the world’s first crowdfunded vibrator.

Their initial success reinforced Chang and Topolovac’s belief that sensual products should look as good as they feel. From there, Crave raised $3.7 million in funding to grow the company and expand its range.

Crave – packing a discreet device

Crave’s design process kicks off with user research. Before pen is put to sketchpad or finger placed on keyboard, hundreds of women are interviewed to find out what kind of experience they are seeking from the product.

“With Vesper, it’s not like anyone filled out a survey form and said ‘Make me a necklace vibrator’. We had broad insights from doing a lot of cultural listening, but no direct customer feedback, and feedback would no doubt have told us not to do it,” admits Topolovac.

The challenge with Vesper was to package the technology in a slim and discreet device. With these specific mechanical constraints to take into consideration, the team got into CAD very quickly. With 3D modelling, they could arrange batteries, motors, circuit boards and other components into as small a space as possible.

For the earlier stages, Crave used a previous CAD system, but migrated to Onshape during the later stages of Vesper’s development. In fact, it was one of Onshape’s first customers when the software launched in 2015. “I come from a cloud computing background, so that aspect appealed, but really for us, one of the huge wins is that Onshape vaporises the whole PDM CAD file management problem,” explains Topolovac.

With the parameters in hand, Chang’s task was then to create a beautiful form for the Vesper. From here, prototypes were built, using Crave’s own in-house R&D facility at its San Francisco office.

“Having under our roof all those machine shop tools and this prototyping ability, which all our engineers and designers have easy access to, has been incredibly important in helping us, I think, get to successful products.

From 3D print form studies to small batch production, we can do it all here,” says Topolovac.

Testing with users

Prototypes are sent out for user testing at various stages throughout the product development process – from early simple prototypes to final prototypes built just before hitting the button for full-scale manufacture. In fact, Crave has a waiting list of product testers.

“These are users that love the brand and so anytime we have products going through this process, we always have prototypes sent out to them so they can give us feedback on the experience,” says Chang.

Vesper, following the first prototype testing, the feedback from users was that it was too big. After a second attempt at shrinking it down and creating more prototypes for user testing, the feedback was that it was still too big.

“So we went back to the drawing board to figure out how we could get super-aggressive on the engineering and find creative ways on how to give Ti an even smaller envelope that she could work with,” recalls Topolovac.

Of course, during the design process, materials sourcing is extremely important, since every component must be durable, body-safe and optimised for performance.

With the Vesper being a piece of jewellery, in particular, highly polished stainless steel was selected as the base metal with a choice of silver, rose gold or 24-karat gold plating.

“While the sex toy category generally isn’t regulated, we work to design our products as if it is, because that’s just the right thing to do for our brand,” he says.

“Silicone is hypoallergenic, so it’s totally safe for the body and, as for metal, there is a good reason why surgeons use stainless steel, as it’s a wonderfully safe material. Also, as so many people have nickel allergies and a lot of plating uses nickel, we are very careful of the colours and plating processes we use,” he adds.

Manufacturing depends on the product in question. Crave now has eight products in its range and a factory in downtown San Francisco with the capability to make initial product runs before production is turned over to a contract manufacturer.

Final assembly is often completed at its own factory, however, to ensure that the products meet the highest standards.

Shedding the stigma

Despite being just five years old, Crave is a growing and profitable business with a strong, dedicated workforce and an equally dedicated customer base that loves its products.

These are sold on the company’s website, as well as through a number of other retailers. Fashion chain Urban Outfitters has recently come on board, and Crave’s co-founders would love to see a time when sex toys are stocked by more mainstream retailers.

“I love what I’m doing. To me, it’s a way to support the sexual empowerment of women,” says Chang. “And until sex toys are sold in everyday venues like the malls or stocked on shelves in retail stores in a very nonchalant way, I’ll keep doing this – because it’s hugely important to who we are as women.”

Crave pleasure tour

One of Crave’s core missions is to encourage thoughtful and provocative conversations about sexuality and desire.

One way to facilitate such discussions is through the Crave Pleasure Tour.

Following its most recent crowdfunding campaign on Indiegogo, Crave has raised the funds for co-founder Ti Chang, together with other members of the Crave team, to head across the US in a 1960s Airstream, stopping at various festivals, museums and universities along the way.

“We have transformed the Airstream into a retail shop as well as what we call the ‘vibrator bar’, where three or four people can sit down with technicians such as myself, who’ll guide them through building their own vibrator,” explains Chang.

This concept is modelled on the Build-a-vibe workshops that Crave has held at its San Francisco factory for a number of years.

It’s not only eye-opening in terms of transforming people’s views of what a vibrator looks like, but it also allows them to assemble one themselves, and so provides a chance to learn about design and engineering.

“I can’t tell you how many women I’ve spoken to at our workshops and on the tour who admit that their first vibrator has been one that they built themselves and they found it to be such an empowering experience,” says Chang.

“It’s one way that we help to create space for conversation, because if we want to move the cultural needle and remove the shame and stigma associated with sex toys, then the first step is to talk about these products and present them in a very nonchalant and open way.”