The Ford Transit relies on its optimised powertrain

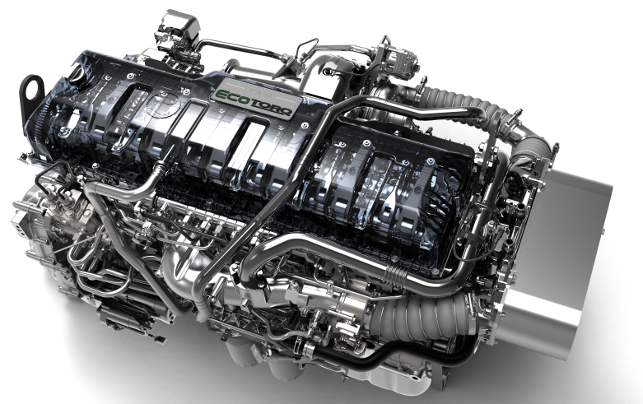

Ford’s next generation of highly efficient Ecotorq heavy duty diesel engine, which has been developed in a joint venture between Ford Otosan and Koc Holding, will go into the new family of Ford Transit vans, people carriers and cargo trucks.

Founded in 1959, Ford Otosan has been home to the Transit range since the mid-1960s, and today has five facilities in Turkey employing 12,000 people producing vehicles for which it has fine-tuned the engineering.

Modern diesel engines are complex assemblies with tight packaging constraints and, due to the higher temperatures as a result of turbocharging, have largely non-uniform temperature distributions which are challenging to predict.

As a result, the need for increased simulation accuracy has seen the rise of multi-component, multi-physics Computational Fluid Dynamics (CFD) simulation as a fundamental requirement inherent in modern diesel engine design.

The Powertrain CAD/CAE team at Ford Otosan use Siemens PLM’s STAR-CCM+ to analyse the thermal exchange between the hot engine gases and various critical solid engine components.

The cost and time needed to manufacture prototypes for testing is driving the increased use of simulation as early in the design process as possible.

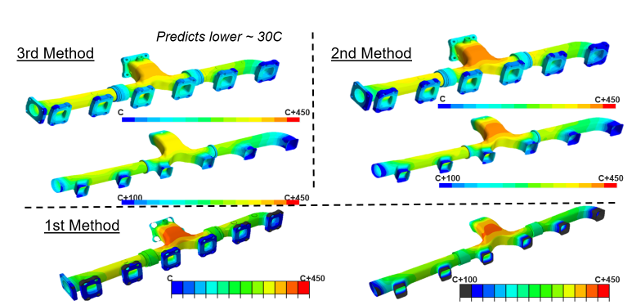

Co-simulation results in STAR-CCM+ (2nd Method) take longer to run than external coupling but give more accurate results

Digital twin

For critical engine components, such as the engine exhaust manifold and the piston head, a co-simulation was used, using a ‘digital twin’ of the parts to help achieve design goals without physically prototyping multiple parts.

As Sinan Eroglu, the CFD supervisor of the Powertrain CAD/CAE group, explains, “STAR-CCM+ co-simulation enables coupling of multi-physics simulations with different time scales ranging from microseconds to thousands of seconds, providing faster and more accurate analyses and shorter turnover times for development and assessment of complex designs.”

The function of the exhaust manifold is to bridge the gap between the engine structure and the exhaust after treatment systems and allow the burnt in-cylinder gases to fl ow through it. Exhaust manifolds are designed and developed to provide smooth flow with low back pressure, whilst being able to withstand extreme temperatures.

As Eroglu explains, “The aim is to come up with a durable manifold design, so accurate modelling of the warm up time is extremely important.

“It is a typical multi-physics problem where there is a strong interaction between the fl uid and solid domains, so the solvers for each of these have to be coupled.”

For cases where a full thermal stress analysis is not required, a STAR-CCM+ to STAR-CCM+ co-simulation can be utilised: here, the finite volume method is used for both fl uid and solid models to predict the thermal distribution.

This allows the data transfer to be handled solely within STAR-CCM+, permitting a more direct data transfer whilst the simulation runs rather than transferring the averaged thermal load at the end of a complete cycle as is the case with the STAR-CCM+ to Abaqus approach.

In this instance, the data was transferred every five ‘fluid’ time steps. Different time steps were used in the fluid and solid models, of 10 microseconds and 0.1125 seconds respectively, leading to a total of 5,333 data exchanges between the fluid and solid models to ensure convergence.

Comparing to the physical test data from engine dynamometer testing, thermal imaging results indicate that there was, at worst, a four per cent over prediction in temperature as a result of co-simulation, and an average over prediction of only 1.7 per cent.

However, comparing co-simulation thermal results to the physical data shows at worst a 9.2 per cent under prediction and an average 7.3 per cent under prediction. This showed that the thermal analysis coupling approach solely within STAR-CCM+ gives an overall close agreement to physical test data, albeit marginally conservative.

Summarising the results from the simulations, Eroglu concluded: “For the 10-minute exhaust manifold warm-up case, the STAR-CCM+ to STAR-CCM+ co-simulation takes slightly longer to run than external coupling but gives more accurate results.”

Ford’s Ecotorq diesel engine

Future engines

With the higher thermal management demands that engines are increasingly being placed under, it is apparent that accurately simulating multiple solid and fluid regions can be handled quickly and accurately within STAR-CCM+.

The future of the diesel engines will focus on efficiency due to forthcoming CO2 regulations, resulting in the necessity to develop engines that withstand higher thermal and structural loads.

STAR-CCM+ provides the opportunity to accurately assess the performance of several engine sub-systems and determine the loads and shape of the components and systems that are affected by complex multi-physics.

cd-adapco.com

Ford Otosan reaps benefits from thermal simulation for its new diesel engines

Default