David Brown Automotive, where the styling may be retro and traditional craft skills still in use, but where engineering and technology are bang up to date. We visit the company’s Silverstone, UK headquarters

There aren’t many cars that bring a smile to the face quite like the original Mini. Its appeal transcends age and nationality, with many people having a story to tell about growing up with a Mini or it being their first car.

Originally launched in 1959 by the British Motor Corporation, the ingeniousness of the Mini’s design by Alec Issigonis lies in the fact that, despite its diminutive size and tiny ten-inch wheels, its interior still feels deceptively roomy.

Many people have restored original Minis and automotive giant BMW has given the brand new lease with its recent beefed-up incarnations – but the model’s essential ‘Mini-ness’ endures, which is what makes it such an iconic car.

Stepping inside a workshop on an industrial unit adjacent to the Silverstone race track, you might well imagine that you’d gone back in time 50 years, as you spy a range of what appear to be original Minis in various stages of build.

On closer inspection, however, you’ll see that these are very modern vehicles. The interiors are plush and luxurious, something few original Mini owners would have boasted about their cars. On the exterior, meanwhile, the distinctive welded seams where body panels were joined together (including the rain gutter on the roof) are gone. Instead, the seams are smoothed out and gleam with a flawless finish and bespoke paintwork.

These cars are all examples of the Mini Remastered from David Brown Automotive. When the model was first launched as a prototype in 2017, the intention was to keep the retro styling and small packaging, but to bring the car up to date with modern conveniences, improve on its engineering and address manufacturing deficiencies.

As Matthew Finbow, lead designer at David Brown Automotive, puts it: “It’s not making it look exactly what it was when it was brand new; it’s taking what was great about the original model and adding even more greatness.”

Each Mini Remastered begins life as a donor classic Mini, which receives a new body shell purchased from British Motor Heritage. But while the body may be new, the 1275cc engine and four-speed gearbox are reconditioned originals.

Aluminium bodywork is formed by hand on a traditional English Wheel

The Mini Remastered isn’t the only car in this workshop. There’s also a production line of Speedback GTs. This 1960s-inspired Grand Tourer was the first vehicle that David Brown Automotive launched as a prototype in 2014, and many of its design details – such as the distinctive grille and tail lights – have been carried over to Mini Remastered.

In complete contrast to mass production, these vehicles are made to order and are entirely bespoke to the individual customer. Each one is hand built, utilising a blend of traditional craft skills, together with modern engineering and production processes.

Whilst a Mini Remastered takes 1,400 hours to build, with 100 currently being produced a year, a Speedback GT, which is based on a Jaguar XK-R rolling chassis and supercharged 5.0-litre V8 engine, takes 8,000 hours to build, with only five to ten produced per year.

David Brown Automotive describes its approach as ‘coachbuilding for the twenty-first century’. As Finbow explains: “Back before modern automotive production techniques saw a car’s chassis and body combined into one large structure, the body would be fitted over the top of a chassis. This body and its interior could be a standard design, but in special cases, customers could commission a coachbuilder to design and build a one-off, bespoke design that would then be fitted over the platforms of the day.”

He adds: “The intention with Speedback GT was to combine that older style of building cars with modern technologies and materials, to create a product that is very unique to the person buying it.”

Of course, exclusivity comes at a price. The Speedback GT (of which only 100 will ever be built) starts at £520,000 (excluding VAT) and the Mini Remastered at a more modest £75,000 (excluding VAT).

Real wood veneers, waiting to be hand-applied to interior door panels

David Brown Automotive – how it all began

The story of David Brown Automotive began with a vision its eponymous founder David Brown had (see boxout below). After competing in an endurance rally, he decided to combine his entrepreneurial flair, his experience of low volume manufacturing and his love of cars to build a Grand Tourer with a classic design but offering contemporary comfort, reliability and performance.

To help him achieve the desired results, he decided to collaborate with an automotive stylist and called on former Jaguar Land Rover head of design Alan Mobberly, who reportedly came out of retirement to work on the project.

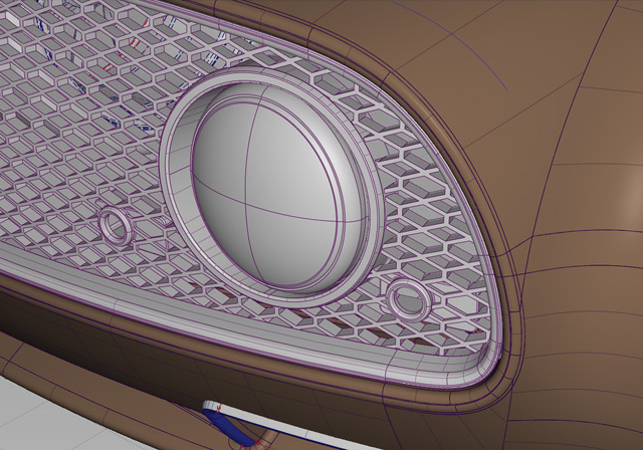

The car was initially designed in Autodesk Alias and the data then used to create a full-size clay model. Following further refinement to the car’s shape in clay, the model was scanned and that data used to create a CNC-milled ‘bucks’,around which the bodywork would be shaped.

This is where traditional craftsmanship enters the development process. Rather than the aluminium body panels being pressed out by machines, they are hand-rolled on an English Wheel, just as they would have been in the 1960s. This work is carried out by a supplier in Coventry called Envisage Group and takes 3,200 hours alone.

The combination of modern engineering and manufacturing processes with traditional craftsmanship is no more apparent than in the wood-veneered door panels inside the Speedback GT. In order to achieve the desired curves, the panels are 3D-printed and then the wood veneers hand-applied on top in a very traditional way.

“It really is the best of the old and the new,” says Finbow. “The substrate is produced with modern techniques and then the finish, which is what the customer sees, is applied using classical materials and techniques.”

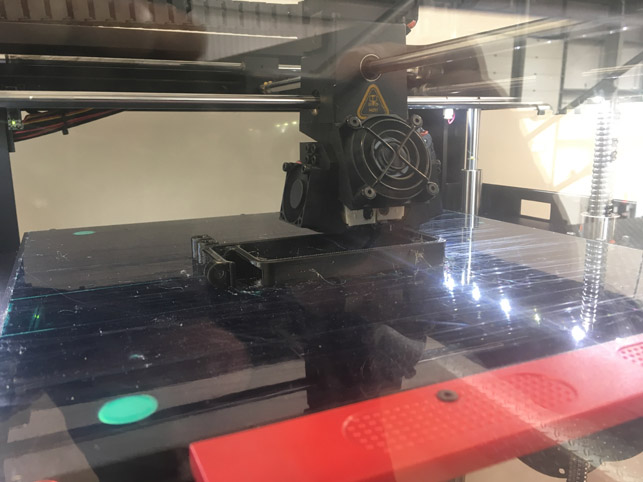

Whilst the interior door panels are 3D-printed off site by a supplier, David Brown Automotive also has its own 3D printers in-house. Humming away along one wall of the trim shop sit two Raise3D Pro printers, which turn out not only prototypes but also end-use parts, including sunvisors, air intakes and the door pockets located next to the rear seats in the Mini Remastered.

“The original intention behind using in-house 3D printing derived from a cost/timing analysis that revealed it would be more beneficial to produce certain interior components using this method, rather than getting tooling produced for them. It also means we can produce extremely complex shapes,” explains Finbow.

Seeing the capabilities of this tool and what could be achieved, the engineering team soon began designing more and more components in Catia that could be 3D-printed using these machines.

“For companies like ours, who specialise in low-volume manufacturing, 3D printing can be of great benefit.

The material cost is not that expensive, it can be quickly and easily replenished, and the final prints (depending of course on how they are designed in CAD) are very lightweight and strong,” says Finbow.

“However, 3D printing is currently still very timeintensive, so it’s generally suitable only for low-volume fabrication. Many manufacturers are hopeful that the next generation of 3D printing technology will improve print times,” he adds.

Inside the cockpit of the Speedback Silverstone Edition

David Brown Automotive – custom made

Walking around the Mini Remastered and Speedback GT models currently being built in the workshop, it’s striking how different they all are, not only in terms of exterior paint colour, but also interior materials and finishes. This is because, as Finbow puts it, “the customer can have whatever they want, within the realms of logic.”

From the outset, customers are invited to visit a customer specification room onsite, where they essentially co-create their vehicle with representatives from the design and marketing teams. “It’s a very collaborative process from the very start – both in-house amongst the different teams, as well as with the customer. So everyone is working together to deliver something that is amazing,” says Finbow.

“Some customers come in with a very strong idea of what they want their car to look like, whilst others are very open to anything. In that case, it is up to us to present ideas and guide them in a particular direction and present a range of different options for paints, leathers, fabrics, stitch colour and brightware finish,” he adds.

Only 100 of the performance-focused Speedback Silverstone Edition will ever be made

David Brown Automotive presents customers with various options through a combination of visualisation tools. “We use Autodesk VRED 3D visualisation software for exterior colour and trim visualisations, particularly for Speedback GT,” says Finbow.

“For interior visualisations (and in particular for Mini Remastered), we tend to work more with a series of master-Photoshop files that have separate, editable layers for all of the interior surfaces of the vehicle,” he continues.

“These layers have been arranged according to our established colour and trim strategy, so edits and alterations can be made quickly and efficiently, and the completed images can then be sent to prospective customers for their sign-off. These Photoshop files also allow for additional bespoke features to be visualised easily, based on specific customer requests.”

With the vehicle specified, customers are then invited to witness the build process for themselves, via an online customer portal. Here, they will see photos and updates regularly uploaded as their car progresses through its thousands of hours of manufacture.

Inside the workshop, various Mini Remastered and Speedback GT models are in different stages of build

In the on-site customer specification room, customers work with the design team to personalise their car

Hand painting a Mini Remastered model is a 400-hour process in total

Inspired by Silverstone

There is one further model in the workshop and it’s the company’s most recent launch: the Speedback Silverstone Edition. David Brown Automotive moved to its new Silverstone headquarters from Coventry in 2017 and to mark the occasion, it designed a Speedback GT that takes its inspiration from the racing circuit’s aeronautical and motorsport heritage.

Having started at the company over two years ago, this is a project for which Finbow was design director and which he saw through from beginning to end. The intention was to keep the basic architecture and bodywork of the Speedback GT, but add in various design cues and features that lend it a more aggressive, performance derived personality.

“My team and I used Alias to model the surfaces for most of the exterior styling features and body modifications. These included the front mesh grille, the side fender vents, the rocker-panel flares, the lower-rear valance, the tailpipe finishers and the custom 20- inch alloy wheels.

In the trim shop, you’ll find two RAISE3D Pro printers at work

3D printers are used for creating prototypes, as well as building some end-use parts such as sunvisors

“The interior surfaces do not deviate in shape from Speedback GT, so no additional 3D Alias modelling was required for the interior. They are, however, trimmed, detailed and finished in a specification that is unique to the Speedback Silverstone Edition and we were able to involve a lot of craftspeople in doing this,” comments Finbow.

This performance-focused model, which delivers over 600hp and is strictly limited to a run of just 10 production cars, was officially launched in 2018. “It was a fantastic project and seeing the covers pulled off of it at the Geneva International Motor Show 2018 was a very proud moment,” smiles Finbow.

So what next? The company says that, for the foreseeable future, it will be concentrating on the two models that it offers today. But with limited production runs, especially on Speedback GT, there can be little doubt it has other retro-inspired ideas up its sleeve.thousands of hours of manufacture.

An Autodesk Alias screenshot of the Speedback Silverstone Edition’s grille lamp

For the Speedback GT, a traditional forming bucks is created using CNC machining

The Mini Remastered is custommade to meet the individual customer’s exact tastes and preferences

David Brown: The man behind the brand

David Brown (not to be confused with the tractor manufacturer and previous owner of Aston Martin) is a British businessman, born in Harrogate, North Yorkshire, and named after his father, who started a company called DJB Engineering in 1972. David Brown Junior was its first employee.

The company designed and manufactured what was, at that time, a revolutionary type of off-highway articulated earth-moving vehicle. The international success of this product enabled the company to expand and by the 1990s, it had over 3,500 employees.

The company was eventually sold to its biggest customer, Caterpillar, in the mid-90s.

At the time of the sale, David Brown Junior was managing director. Just two weeks into his subsequent retirement, he realised that there was still a lot he wanted to do and so began his entrepreneurial career.

In fact, he founded over 30 companies, mostly in the lifestyle sector, including Harley Davidson dealerships, high-end restaurants and a chain of clothes shops.

These businesses were mostly sold around 11 years ago, although Brown retains a few, including a brewing and distilling company called BAD Co, a highend home development company called Roque Properties and a luxury stone surface specialist called Lapicida.

Either way, he has had more time since the sale to pursue some of his other passions, including his love of cars – from building them to racing them in gruelling endurance rallies.

It was actually one of these rallies that ignited the spark that led to him creating his own classic Grand Tourer.

He remembers borrowing a Ferrari Daytona convertible for a race and feeling immensely unimpressed with its heavy steering, poor brakes and lack of power.

He eventually abandoned the race when the car broke down but, not wanting to miss out on the rally, decided to hire a Peugeot and follow the rest of the drivers in comfort, with the modern amenities of air conditioning, power steering and a radio.

He came back from the rally thinking that it would be great if he could combine a retro-designed package with a contemporary powertrain and all the conveniences that come with modern vehicles – and so he founded David Brown Automotive in 2013 to do just that.

In this venture, Brown utilised his engineering and manufacturing experience together with his love of design and entrepreneurial spirit to produce a beautifully, handcrafted classic Grand Tourer in low volumes.

Inside David Brown Automotive where styling is classic but the tech is 21st Century

Default