Styled to capture the characteristics of Nike football boot types, the sculptures each have unique characteristics

Sneaker launches are big business, with few more so than those taking place in a flagship London store during an international football tournament – hence Nike wasted no chance to upstage rivals with four incredible golden footballs.

Glimmering, geometrically unique and styled to capture the characteristics of the brand’s signature football boot types, each of the balls was placed to showcase a new off-pitch Nike F.C. sneaker that mirrored its on-pitch equivalent.

The polished final line-up await being placed into displays

The original campaign for Nike, developed in time for the UEFA European Championships in summer 2016, was produced by Madrid-based creative agency Tavo. Using Cinema 4D to create graphics and animations, these designs were then developed and made physical using traditional hand modelling skills, sculpting all four balls.

Although the results were effective, London-based 3D printing bureau Digits2Widgets (D2W) was approached to see how the designs could be advanced to produce the same results faster and more accurately to the original digital designs.

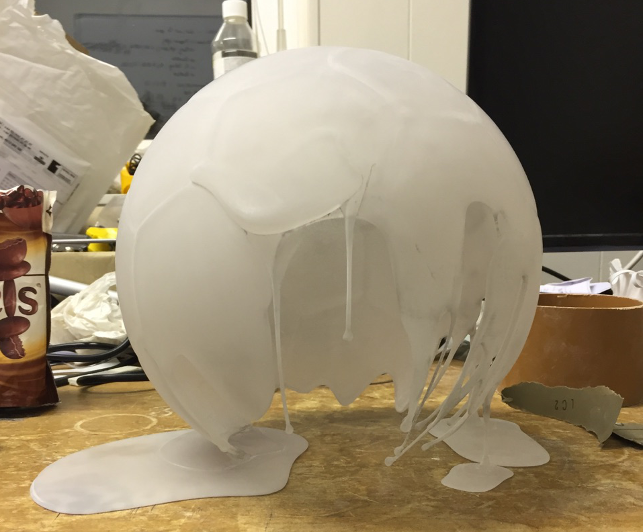

Underneath it all lies a SLA 3D printed base, produced on a 3D Systems iPro 8000

D2W’s in-house CAD designer took all the original Cinema4D 3D models and exported them as STL. “We helped to complete the process by using Materialise Magics software, which makes the files printable in the SLA material,” adds D2W CAD production manager Bart Radecki.

Although 3D printing the balls in real gold is a possibility, the cost and time involved meant that gold plating during the post processing stage over a smooth plastic would be much more economical.

“All parts were 3D printed in resin which has a high resolution, giving us the ability to create sharp detail on the individual designs of each ball.

A nanocrystalline copper plating forms a base for the gold to attach

“The joy of using rapid prototyping is that you can print off more than one, so if one breaks, for example, it’s relatively easy to replace, unlike the lengthy process of hand carving a new one from scratch.” The parts were printed using 3D Systems’ iPro 8000 with its proprietary Accura 25 stereolithgraphy material.

With only two weeks to prepare the CAD files, print four complete footballs, electroplate them to a high standard, gold plate and finish each one, before delivery to the client, the pressure was on right up until the final whistle.

“If one of the SLA balls had broken then, given the size of the print, it would be another 24 hours to print a new one,” explains Radecki of the delicate project.

The final product in the Nike Store alongside its corresponding sneaker

“Pressure does bring out the best in people’s ability, so although at times production was difficult, it was also an exciting challenge to be a part of.”

Once the printed parts had been cleaned, a nanocrystalline copper plating was added, giving a smooth and even base all over the resin part, which makes it easier for the product to be gold plated in the final stages.

Some final polishing brought out the full detail of the gold drips, sharp edges and the football’s stitched panels, before the displays were erected, complete with partnering footwear, for the Nike Town store in London.

Nike’s in-store sculptures get the gold treatment

Default