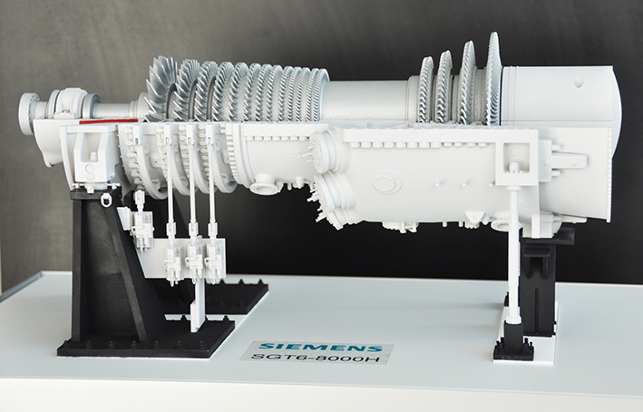

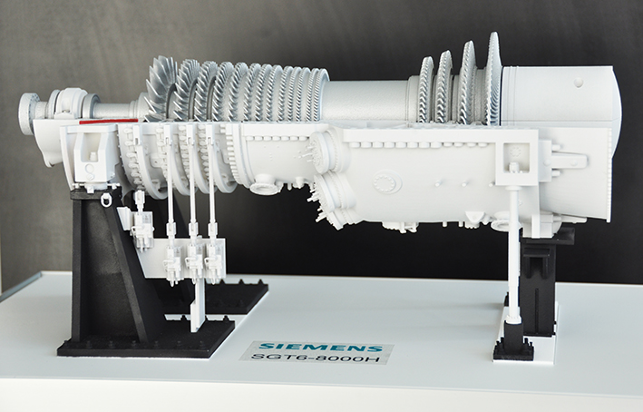

In a bid to create one of the most efficient gas turbines in the world Siemens has produced the SGT5-8000H, which boasts a gross power output of 425MW. The Siemens Energy Sector team based in Görlitz, Germany, was keen to showcase the capabilities of this turbine at trade shows and customer presentations and so turned to its partner in the 3D printing arena – Berlin-based 3YOURMIND – to help it produce a scale model of the turbine.

Siemens and 3YOURMIND have worked together since 2013 on various projects but for this most recent one, because the SGT-8000H series turbine represented such a large efficiency gain, Siemens wanted the model to showcase these advances. 3YOURMIND proposed a motorised model to illustrate the movement of the turbine. This would not only be eye catching but would also help representatives explain the unique flow processes within the turbine.

“Siemens wanted to make a more significant impact with this model, so the size is larger than previous models we’ve done, the model has been painted to increase the realism and the motorisation was added in order to better visualise the air-flow within the turbine,” explains Brian Crotty, marketing director at 3YOURMIND.

The size decided upon was 40cm – a scale of 26:1 from the orginal, which stands at 10.5 metres tall. “This size was determined to be the optimum for display purposes as a high level of detail in the geometry can be preserved and it would still be easy to transport,” says Crotty.

Getting ready for print

Time was of the essence because the Solid Edge CAD data was provided to the 3YOURMIND modelling team just five weeks prior to the first live presentation of the turbine.

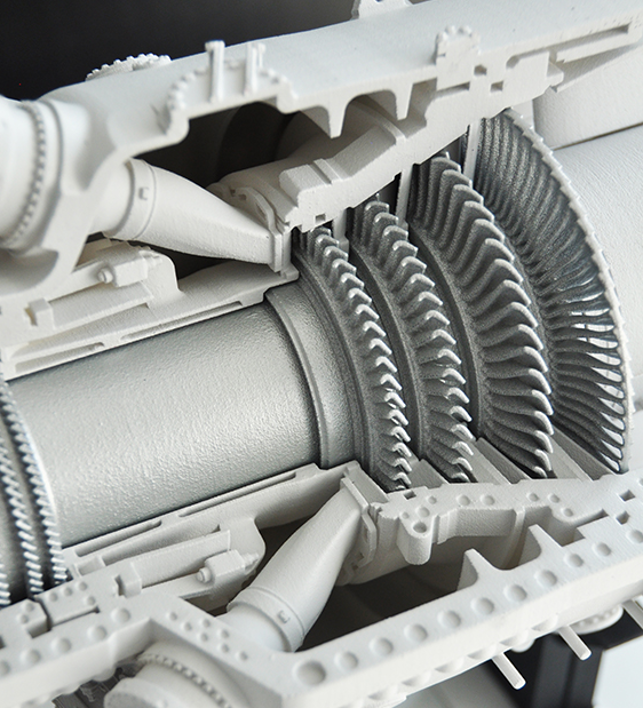

The team had to adapt and scale the parts before the model could be 3D printed. And it’s not just a case of shrinking the model down either. In fact, Crotty explains that a complete recreation of the model was needed.

“Every detail was individually analysed and then either kept, remodelled or rejected. Small details such as screws are removed to reduce ‘noise’ on the final print.

“We also had to combine design components into single parts and some parts of the model had to be made modular such as removing the upper casing. And, of course, the motor and bearings had to be added into the design,” he comments.

The turbine’s rotor is propelled by an electric motor and hiding the DC stepper and driver, which is operated by a remote, within the 3D print proved challenging. “Since this was the first motorisation, we tested three different strengths to determine the best speed/force ratio for the model. The final model can actually alternate between three different speed settings,” says Crotty.

Siemens and the team at 3YOURMIND worked together to create a functional, motorised 3D printed turbine model of the SGT-8000H series turbine that could be showcased at trade events and customer presentations

Hiding trade secrets

Also, a key consideration whilst working on this model was to ensure that they were masking any of Siemens’ trade secrets. “The confidentiality of the designs we are working with is one of the most important services that we offer and is a cornerstone to our online platform and to the specific custom projects that we complete.

“In addition to file security while transferring the digital designs, we went through an approval process with Siemens for each step of the design creation,” says Crotty.

In addition to both a motorised and static version of the model, Siemens also requested two other sizes of the model for different display scenarios.

When ready, the various models were sent to one of 3YOURMIND’s vendors on its online 3D marketplace, which enables users to upload a 3D file and then compare prices of various 3D printing vendors.

“We currently have over 40 services offering 3D print services around the world, so we can provide quality prints for any need,” explains Crotty.

For this particular project, 3YOURMIND decided upon the SLS additive manufacturing technique and the materials Aluminide for the turbine and Polyamide for the casing.

“This material had the versatility that we needed. It is durable for travel but with enough level of detail to show the complex parts of the model. It made for a low grade of design restrictions and was paintable,” he explains.

Siemens were so pleased with the result and the feedback the model received that it requested that 3YOURMIND produce a whole series of smaller versions to be used as giveaways.

“Because we had already done the work with the larger models to adjust the geometry, we could downscale them to the desired size and reuse a majority of the work. We did need to adapt the geometry of parts that had become too small, but the new size significantly reduced the level of details,” explains Crotty.

“It was a challenge to preserve a movable rotor in the small turbines – multiple pilot models were made to make sure that the unsintered powder can be completely removed from the cavities behind the rotor. It is not motorised, but still freely spins as a single print.”

Scaling down a 10.5 metre tall Siemens gas turbine

Default