Composite chassis free-size optimisation using OptiStruct

Sit-ski could open up new ways for disabled skiers to conquer the slopes, thanks in part to the use of simulation tools from Altair

The National Composites Centre (NCC), established by the University of Bristol, is an open-access, industrial-scale, state of the art non-profit UK facility for technology development in the manufacture of advanced composites.

With a mission to accelerate the growth of UK industrial output by enabling design and manufacturing enterprises to deliver winning solutions in the application of composites, the facility has doubled in size since it first opened in August 2011. The NCC is the primary composites catapult facility in the UK and serves as an integral part of the UK’s composites initiative since the government launched its Composites Strategy in November 2009.

Final design of the Sit-ski

Mono-ski or Sit-ski

Simulation plays a key role in the design, analysis and validation of complex systems and structures in composite product development. It is of primary importance to the industry, especially in considering the use of composite structures at an architecture/system level.

Recently the NCC, in collaboration with the Manufacturing Technology Centre (MTC), Advanced Manufacturing Research Centre (AMRC) and University of Warwick (WMG) worked on a collaborative project to develop a Cross-Catapult technology demonstrator: the Mono-Ski or Sit-ski, a sports device that uses adaptive equipment on mountain slopes and is designed for individuals with lower extremity limitations.

The team worked together for the design and manufacture of the Sit-ski to understand the performance of existing Sit-skis, build kinematics models of suspension behaviour and design a system to showcase the Catapult Centre’s technologies and capabilities while delivering performance improvements for skiers.

Double Paralympic downhill skier Anna Turney takes to the slopes on the prototype

Sit-ski – simulation in the design process

The Centre uses simulation tools all the way through the development cycle, from micromechanical material modelling to conceptual design, detailed structural analysis and manufacturing process simulation. The team there understands the importance of cost and manufacturability in product development and uses simulation to help make better decisions in shorter time-frames.

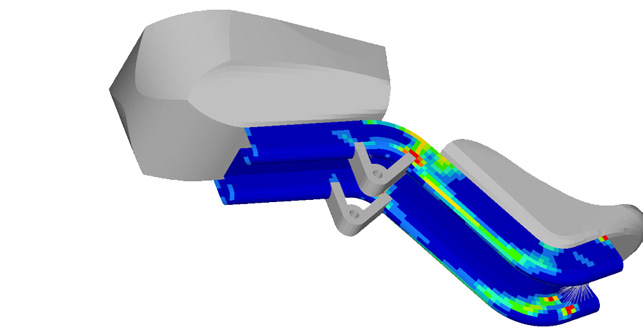

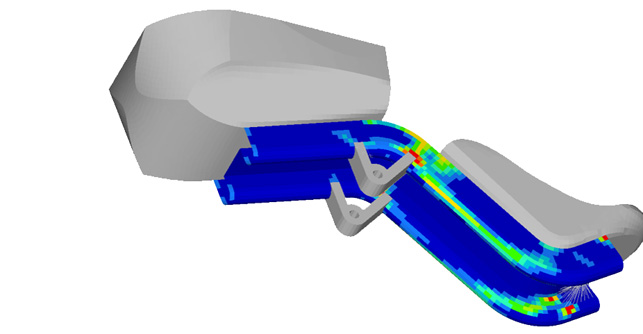

Composites were used extensively in the new Sit-ski design, with the Altair HyperWorks suite being utilised throughout the development process. Altair MotionSolve was used to model the kinematic behavior of an existing coil-over suspension system with 4-bar linkage and compared to the new composite leaf spring and damper concept.

Altair HyperStudy was used in conjunction with Altair MotionSolve to optimise the kinematic behaviour and assess the positions and sizes of various structural and suspension elements (including sizing of the spring using Non-Linear FE).

Altair OptiStruct was used to perform detailed sizing of laminates in the spring and chassis elements, along with the use of the morphing capabilities in Altair HyperMesh to optimise the geometry.

Altair Inspire and Altair Evolve, also included in the Altair HyperWorks simulation suite, were used as a convenient means of visualising the full assembly and producing images for the reports and presentations.

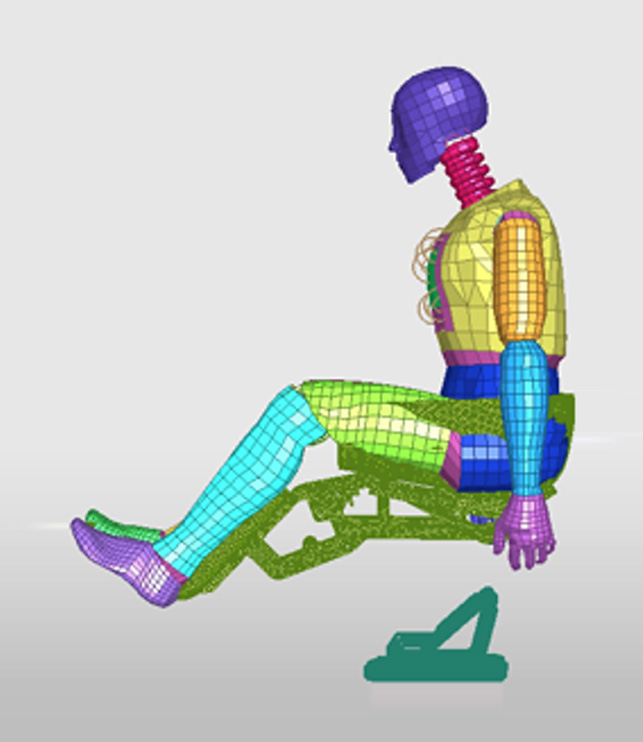

Dummy model position

Great potential

“One of the key successes from using a combination of Altair software products was the ability to carry out an entirely virtual assessment of performance and structural reliability before a single tool or component was manufactured.

The whole process from concept to manufactured assembly took less than three months and would not have been possible without the help of the virtual design tools,” says Andrew Patterson, engineering capability lead for conceptual design and DFX at the National Composites Centre, the overall technical authority for Sit-ski systems integration and assurance.

Physical testing carried out at the component and assembly level validated the models, demonstrating good correlation with the predicted response of the spring component and overall kinematic behavior of the assembly.

Full-scale structural test of the optimised design

The resultant initial design of the Sit-ski is about 15% lighter than other similar devices available on the market, including some fairly substantial topology-optimised aluminium brackets used to ensure sufficient safety factors and fitment of the suspension components.

Skiers feel that the device is different, they’re excited by its potential and say that they would like to see it developed further.

The National Composites Centre’s Sit-ski takes to the slopes with Altair

Default