SimpoEdge

Supplier Simpoe

Description SimpoEdge is a plastic injection simulation solution integrated into the Solid Edge graphic user environment, which can optimise the design and tooling of plastic parts.

Injection mould tool simulation is all about reducing the risk of errors in production by giving the design and manufacturing team insight into how a tooling stack will operate based on a given configuration of geometry (part design, gating and runner design) and operating parameters (such as melt temp, pressure, as well as cooling channel design).

The program runs within the familiar Solid Edge user interface, making it relatively simple to operate the powerful pre–and post processing technology, with the idea being to ‘close the loop’ of plastic part design and manufacturing optimisation, however complex the geometry of shell and solid parts.

With plastics in mind, SimpoEdge has a number of features for packing simulation, thermal exchange regulation, and even for simulating the complete part deformation due to warping and material shrinkage, as well as the material database of more than 5,000 materials, which can also be customised with a few clicks.

The base package (SimpoeXplorer) includes all this, plus there are three variations that add on specific benefits for engineers, toolmakers and manufacturers such as multiple gate optimisations, and cooling simulations.

Price On application

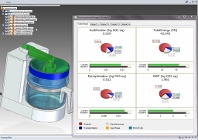

EcoDesigner

Supplier Trayak

Description Originally released with Solid Edge ST3, EcoDesigner has become one of the established green product design applications, tightly integrated into the CAD package.

The software allows the product engineer to easily analyse the environmental impact of the design using a Life Cycle Analysis (LCA) ‘first pass’ that works directly on parts, assemblies and sheet metal components before you go too far.

It offers the flexibility to choose an impact assessment method and indicators that make the most sense for your products, operating conditions, geography and industry.

Working from peer reviewed and industry accepted data sources for its analysis, EcoDesigner is also an open architecture system that allows a company to add in its own proprietary material and environmental analysis data.

On install, it supplements the entire existing Solid Edge materials library with the LCA data required for each entry.

The system automatically picks up any assigned material, weight and volume of all the parts in the assembly for the user to then experiment with different materials.

The ST5 release offers new functionalities such as multiple part changes in one easy form; graphical visualisation of best and worst parts in the assembly, and the ability to run, compare, save and load different scenarios based on materials, processes and even transportation data.

Price Both licence andsubscription model available

Inforbix

Supplier Inforbix

Description For Solid Edge users, a big challenge is presented by the growing amount of product data, and how to aggregate, access, and find the product data they need simply and quickly from across various locations and file types and locations throughout the company.

Think of Inforbix as an online, cloud–based, product data searchengine for CAD that enables Solid Edge users to find and extract data and reduce the time lost or wasted searching for information, while effectively increasing product data reuse.

It is used not through Solid Edge, but via a standard web browser, and can easily access product data within CAD, PDM, and PLM.

All Inforbix apps utilise product data semantics technology that automatically infers relationships between disparate sources of data. For example, Inforbix can semantically connect or link Solid Edge CAD assemblies with a related Excel or PDF file containing a bill of materials table stored on a file server in another department.

A big benefit here is that users are made aware of useful data they may not even know exists, while the source material isn’t actually touched, moved, or migrated to the cloud.

Price On application

SigmaNEST

Supplier SigmaTEK

Description SigmaTEK is a provider of manufacturing process efficiency software, with its flagship product SigmaNEST being one of the leading CAD/CAM ‘nesting’ softwares.

Its program takes a 3D model from Solid Edge, automatically strips it into the necessary parts for cutting, and ‘nests’ the parts in the most efficient and effective manner possible from your predefined sheet materials.

Slashing scrap and maximising machine cutting efficiency and time for all cutting, punching and router machines.

This is perfect for Solid Edge’s vast user–base in the manufacturing sector including metal shops, steel service centres, OEMs and suppliers of all types and sizes, allowing them to maximise throughput and significantly reduce overheads.

Version 9’s user interface uses a familiar menu ribbon making it simpler to use, while new part/sheet fill colour combinations allows for better visualising and distinguishing parts. Meanwhile a selection of intuitive icons and the ‘Quick Find’ and ‘Feature Tree’ functionalities helps speed up the process.

Increasing material cost savings is the big plus with SigmaNest, while the software itself is flexible enough to incorporate a wide range of machinery, regardless of type or brand, making it a singlesource programming base for production engineers.

Price On application

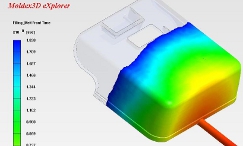

Moldex3D eXplorer

Supplier Moldex3d

Description Moldex3D eXplorer is a quick part verification tool embedded into Solid Edge giving industrial designers an easy to understand validation tool to check parts for manufacturing

when creating a CAD model.

With its professional filling analysis capabilities, major moulding problems, such as flow imbalance, air traps, weld lines, and design mistakes can be simulated and discovered in the early design phase, enabling the user to spend more time on the designs.

It’s a versatile product, cutting out the need to simplify designs into 2D plans, and letting you export your models in neutral formats such as IGES, STEP or STL, or as a part geometry, runner layout and cooling channel layout from the CAD.

Any detailed definition that needs to be added can be done using Moldex3D Designer or Moldex3D Mesh.

For those of you hooked on hardware speeds, Moldex3D eXplorer utilises each core of the modern CPU architecture (maximum four cores) for its quick analysis. Once completed, a report generator enables users to share reports with the product design team, clients, suppliers and moulders.

It has a diverse impact on many industries, regardless of how delicate or complex the product design. It’s a great tool for predicting potential mouldmaking blunders.

Price On Application

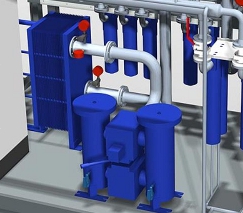

Smap 3D Piping

Supplier SMAP

Description Developed for planning complex 3D piping systems for machinery and production plants Smap3D Piping is completely integrated into Solid Edge via its XpresRoute add-on.

Solid Edge’s PathXpres within XpresRoute enables designers to rapidly define a 3D tube or piping path without drawing the individual lines of the path, generating the optimum route for it to take.

The addition of SMAP’s software ensures that the complete piping assemblies are generated along the path automatically, using the correct bends, pipes, tees and flanges.

It includes an extensive library of different types of piping and many intelligent functions: should a change be made along the design, it automatically swaps all the components and pipes that are affected by the change.

The user can also define new pipe classes very easily by setting the material, diameter, pressure, temperature and so on for the individual components. SMAP 3D also supports the production of pipe bends or specially adapted curved pipes, besides standard curved fittings, as a basic function.

With Solid Edge customers producing large–scale machinery and even plant designs, SMAP covers P&ID diagrams, 3D planning and accurate isometrics, automating the designs to help save time and

cost while avoiding the need for expensive reworking.

Price On application

PARTshare

Supplier Striker Systems

Description Striker Systems’ PARTshare is an advanced library system that provides storage and retrieval of sheet metal parts and assemblies along with any associated manufacturing data, allowing Solid Edge users to share flat part data with CAD/CAM and Nesting software in real-time.

Working directly within the Solid Edge user interface, individual sheet metal parts or entire assemblies can be released from the Solid Edge modelling environment, automatically unfolded (as necessary) and placed in the PARTshare library.

Critical part data including part number, revision, and material parameters, are all maintained to facilitate manufacturing operations.

Once the parts are in the PARTshare library they are immediately available to users of Striker CAD/CAM and Nesting software (needing no further importing of parts) and can be individually programmed or nested for CNC punching and cutting machines.

This is for a larger outfit, with a typical configuration for PARTshare including several Solid Edge designers and one or two Striker CAD/CAM programmers, all accessing a common library, although, comparing this to the conventional method of opening each Solid Edge part model individually and saving a flat part, the timesavings can be huge.

Price On application

Seven apps aiming to improve the design and manufacturing process

Default