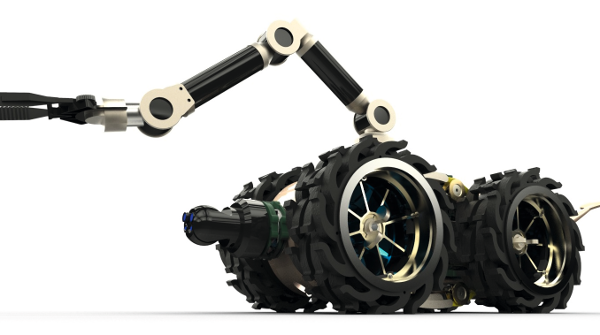

Philip Norman tests a naked EXTRM SC 2.0 robot platform outside the company’s headquarters at Lowgrounds Farm Yard in Buckinghamshire

Philip Norman is a classic British polymath. He’s an architect, an artist, a published author and illustrator of children’s books (we recommend The Carrot War, if you can get hold of a copy). He’s also an inventor of robots.

Robots, he says, can be relied on to perform many tasks more reliably and cost-effectively than humans. They don’t need food.

They don’t get bored. They’re happy to work 24-hour days and they don’t complain about workplace conditions.

They also represent a vast and growing market opportunity: the industrial robotics market alone, worth $26.8 billion in 2012, is forecast to reach $40 billion by 2020, according to recent estimates from Allied Market Research.

Robots, in other words, are big business — and it’s a business to which Norman is keen to bring new thinking, new flexibility and what he terms ‘modularity’, via his Marlow-based company, Ross Robotics.

Norman is joined by Ross Robotics team members on the front lawn of company HQ

Curiosity about the design systems found in nature is what originally led Norman to start exploring the notion of 3D modularity almost two decades ago. In the late 1990s, with small children at home, he developed a modular child’s toy – but with a background outside of the world of engineering, he’d always tended to use a rather traditional process to capture his ideas.

“I was drawing this with ink and all sorts of instruments, protractors and set squares and the like,” he explains. “I showed these drawings to an engineer friend who worked at Aérospatiale building big jets, and he looked like he’d seen a ghost and said ‘Haven’t you heard of CAD?’”

Norman had previously downloaded 30-day trials but hadn’t got on well with the software. But after a party in 2013, Norman’s friend gave him an impromptu demo of Solid Edge at midnight and, within 24 hours, he was completely won over. “Suddenly all my ideas came alive in 3D,” he recalls.

With a more powerful toolset now in place, Norman explored his idea of a modular toy, refined it and patented it. He very nearly sold it to Hasbro. “It didn’t happen in the end,” he says. “I didn’t get showered in gold and I was left holding my patent, my designs and a big problem burning in the middle of my life, wondering what to do with this thing.”

New directions

The answer, when it came, was to take the same core idea of modularity and switch the focus, from the high-volume, low-margin world of toys, to the low-volume, high-margin world of robots.

Norman spent a year doing research into markets that he thought might benefit the most and began developing a modular robotics system that could operate in environments that humans might find inaccessible or unacceptably hazardous.

Modular assembly of the Armourdillo robot platform

“My goal was to build a system of components that could be assembled and connected, in the dark, on an oil rig, by someone who doesn’t really understand [robots] and have it just work,” he says. At the same time, he adds, the resulting robot needed to be very robust and affordable, “so that anyone that needs it, can buy one and use it.”

Norman looked at the typical connector companies that might take on this type of work and pondered over what he could bring to a design that they couldn’t already access. Quickly, he realised that the same universal connector design that he had developed for his toys could be reconfigured and made suitable for the robotics world.

Taking things further, through research into metallisation of plastics, he also realised that these same mechanical connections could become the means by which power and data signals might be passed around the robot.

It’s this combination of both modularity and simple connectivity that has enabled Ross Robotics to develop a range of robots to serve all manner of industries and solve complex tasks. The company has also coined (and trademarked) the term ‘robosynthesis’.

As Norman explains: “Robosynthesis is literally the synthesis of robots. To date, robots have been designed from a blank sheet to perform a specific task, an approach based on a philosophy of product development-and-delivery inherited from the industrial era.”

The EXTRM SC2.6 robot platform in short wheelbase configuration

“Robosynthesis technology is based on a completely different philosophy: instead of designing and building robots to perform a specific task, we design and build generic robotic building blocks, which can be combined to make robots to perform a wide range of tasks.”

These tasks are, in general, specified by the customer, he says. “This approach turns the conventional productprovision model on its head. Conventionally, the manufacturer provides a product that the customer has to adapt to. With our approach, we recognise that the customer has the closest knowledge of what is required and our system is designed to adapt to that requirement.”

“We’ve taken this route because, in our analysis, one of the major impediments to the development of the emerging mobile robotics market worldwide is the challenge of integrating different systems to create the many different and highly specific unmanned systems that are required,” he continues.

There’s a need, he says, for unmanned mobile systems to replace human beings in harsh environments such as are found in industries such as offshore oil and gas, mining, disaster relief, nuclear decommissioning and agriculture.

“These needs can only be met if the cost of integration, the long lead times involved and the resultant complexity for the end user are dramatically curtailed.”

Assembly of a Motor Module with the PowerCube

At present, Norman and his team are developing a range of modules for the company’s robotics platform, from a single power source – the Power Cube – that connects directly into every other module. This can process data signals to a range of movement assistance devices, from all-terrain wheels to special purpose paddles for navigating pipes. The modular nature of the design means that the same design can be reused at a variety of different scales.

Norman is particularly proud of the work that Ross Robotics has done on the Power Cube. “We’re working towards making this completely loom-free. Inside the pod are contacts that get demetalised and that creates the circuitry. We’re making our own batteries, because we can give the customer what they want and take a lot of the cost out. We’re just buying in these Panasonic cells and dropping them into the structure,” he says.

“The point is that we can make a battery, monitor every pair of cells for power management and then bring the data up on a demetalised part, so we won’t have any wiring. That makes it cheaper (because there’s less assembly) and more robust as there’s less to rattle free.”

An amphibious eye: the iBOID can swim as well as tackle tough terrain and might prove useful in surveillance work

One of Ross Robotics’ earliest customers was the European Organization for Nuclear Research (more commonly known as CERN), which is using one of Norman’s first robots to conduct routine maintenance in an environment that’s highly hazardous to humans.

The nature of the Ross Robotics’ platform and its construction using plastics means that this device can operate in the highly charged electromagnetic atmosphere of the Large Hadron Collider, where more metallic robotic solutions would fail to perform.

In fact, says Norman, a protective frame built to protect a Ross Robotics machine is now used as a doorstop in his customer’s office, while his invention roams the facility with no problem.

The relationship between Ross Robotics and CERN is ongoing, with the two organisations working to co-develop a range of robotic systems that can continue to operate reliably inside the Large Hadron Collider, even as background radiation levels increase and the magnetic fields required for experiments grow stronger.

“The advantage for CERN in working with us is that our system can be available 100% of the time,” says Norman.

“Breakdowns (if they occur), upgrades and modifications can all be resolved in minutes by swapping modules.

CERN does not have the resources to operate a large and sophisticated robotic fleet unless that fleet can be kept operational with minimum effort and cost. It can also develop very specific robot applications in a fraction of the time and at a fraction of the cost [that would be incurred] were it to go down the conventional engineering route.”

Future challenges

The Power Cube that lies at the heart of all of Ross Robotics’ designs

Ross Robotics is also developing a range of ready-to-ship products that customers can build upon, adding their own sensors and other equipment to solve particular tasks.

The EXTRM is a fully modular robotic platform that allows for an extremely wide range of robots to be built from the same parts. As needs evolve, the robot can be reconfigured to suit new environments, operations and payloads.

It features four wheels (or other traction methods), a central track that enables it to roll over obstacles that might otherwise ground it and can be fitted with all manner of additional devices, from robot arms, cameras, sensors and other equipment. Interestingly, the whole base platform weighs just over 30kg, can run for 2 hours (expandable up to 4 hours) and has a top speed of 6 kilometres per hour.

The iBOID, on the other hand, is an amphibious device that can swim as well as tackle tough terrain and is intended for surveillance and monitoring.

As the business grows, Norman sees challenges ahead. “Modular robotics requires a constant watchfulness to ensure that the modularity remains robust.

Modules must be recombinable in anticipated and unanticipated configurations without loss of functionality. Ideally, a modular system should perform at least as well as a designed-for-purpose system,” he explains.

“If it can outperform task-specific systems, then that is a plus. To achieve this, the modular architecture has to be consistent at all levels – physical, electronic and software. This means thinking through configuration scenarios and working very closely with electronics and software engineers, clarifying the steps when specifying the product and recognising inconsistencies at as early a stage as possible.”

Illustration from Norman’s original patent, US 20130102221

It also means maintaining an awareness of technologies that are available and bringing them into the process, he says. “For a system to be robustly modular, the physical elements must be able to assemble with one another at variant angles in three dimensions and the electronics architecture needs to be distributed, as there is no ‘central’ element. The software needs to understand the architecture and adapt accordingly.”

Despite these hurdles, Norman is enthusiastic about tackling new opportunities as his company spreads both its wings and its customer base. “We’re starting to work in adjacent sectors, notably oil and gas and agriculture, where the requirement is to reduce cost by streamlining existing working methods.”

In many sectors, he says, using human labour becomes nonsensical once robots are adopted. We’re often told that the robots are coming – but Norman jokes that the phrase needs updating. “The modular robots are coming,” he says.

Biomimicry in practice

One of Ross Robotics’ early customers put in a request for a robot that could ascend steel staircases found in industrial facilities.

Traditional wheeled robots struggle with this type of task. For inspiration, Norman looked to the natural world.

As he explains: “We took inspiration from the cockroach, which can work in very unstructured environments.

Obviously we didn’t want to build robotic cockroaches, but we could look at how they solved problems and adapt that to our needs.”

The trick, Norman explains “was to develop a set of legs on a revolute axis that could self-correct without any additional, higher-level intelligence, much like the cockroach. The legs we designed are passive/adaptive systems, so that no matter what the terrain is, they tend to do the right thing.”

The end result was a wheel with bi-directional flexible flippers, which can climb difficult terrain without the need for additional assistance.

“Once we’d come up with the idea, it developed very quickly. We did a lot of very quick field testing, tried it on different obstacles and tuned it so that the materials and the geometries eventually gave us the desired result.”

Ross Robotics’ modularity mission

Default