www.driveworks.co.ukLet’s start with a question. Why do we use Computer Aided Design (CAD) tools? The number one reason is editability – the ability to dive in and edit geometry, be that a 2D drawing in AutoCAD or a complex 3D model. Before CAD, editing engineering information involved razor blades and a whole lot of scratching, which for those that remember the pain is incentive enough!

The second reason is reuse. By having access to all of your design data in a digital format, you can reuse almost any portion of anything, from blocks and Xrefs in AutoCAD, through to complex sub-assemblies in 3D modelling systems that adapt to their surrounding components.

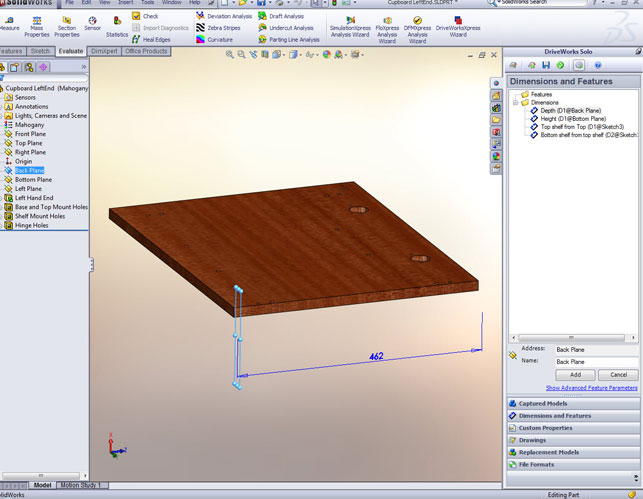

One of the first steps is to capture dimensions and parameters from an existing SolidWorks assembly

The third reason is related purely to 3D working practices and is the removal of ambiguity. Orthographic drawings are possibly the most complex way to show how a part, assembly or product will look. Yes, they are still heavily used, but the point is that by taking advantage of collision and interference detection tools within 3D, we can ensure that parts fit together, sub-assemblies do not interfere with each other and the whole thing, when built, works.

For me, the fourth and fifth places are tied. Simulation tools allow the performance of a product to be tested, before it comes even close to a physical manifestation. This is incredibly powerful, but despite the marketing claims of vendors, has yet to go mainstream. Tied with simulation is automation, something I’ve been a great advocate of for many years. Modern CAD systems allow incredible levels of intelligence to be built into near fully functionally digital models and if used properly and appropriately can provide huge benefits. This is particularly true when applied to a family of products that are based on the same core design, but adapted to fit customer or user requirements. If the intelligence is built in correctly, simply by tweaking the inputs, huge amounts of time can be saved designing different variations on what are essentially common parts, sub-assemblies or even entire products.

The problem with automation is that it is typically very difficult to manage on anything other than the most basic of components or assembly stacks. What you need, particularly if you’re a SolidWorks user, is DriveWorks.

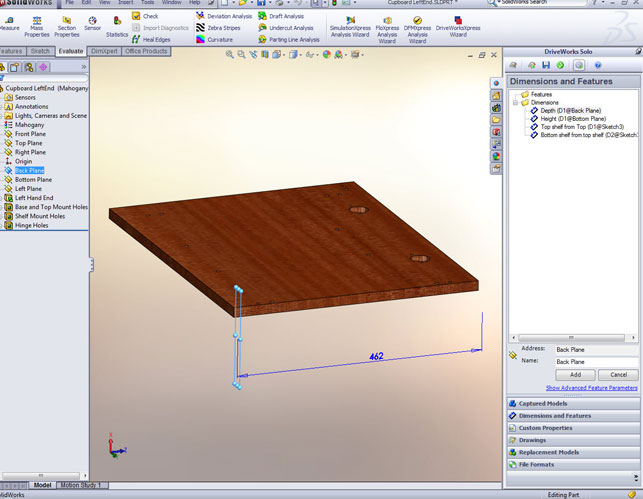

DriveWorks Solo allows users to capture, drive and automate the creation of drawings

DriveWorks is a British company I’ve come to know well over the last ten years, and I’ve watched it evolve from a one-man company with a bunch of Excel macros into a global company with a much more sophisticated toolset with seats installed in the US, Australia, Europe and many other geographies. While there have been many other design automation vendors within the SolidWorks space, none have achieved the traction of DriveWorks. This was cemented two years ago when DS SolidWorks incorporated DriveWorksXpress into SolidWorks, providing every SolidWorks user with basic design automation tools to experiment with.

Alongside DriveWorksXpress, the company has always had its higher-end, DriveWorks Pro, offering for those looking to push automation further. This allows team wide access to the technology to push design automation tools into the hands of non-expert users, such as those in field sales, or customers through a web-connected server. The problem with DriveWorksXpress and the higher-end offering is that the gap between them has always been quite wide. And this is where DriveWorks Solo fits in.

The underlying concept behind DriveWorks Solo is that it brings the most popular capabilities of the full DriveWorks Pro software to the single seat user. It provides the ability to set-up standardised products and product ranges, with all of the appropriate design inputs, alternatives and variations, and then have the system automatically generate 3D models and drawings for each required variant. However, if you want to open up this automation to a wider audience of non-expert users then you need to buy the Pro version.

The practicalities

Once DriveWorks Solo has been installed as an add-on in SolidWorks, it will appear in the task panel and it’s from here that everything within the system is driven.

The first step is to create a new project and within that project, there can be multiple rules-based products to work with. To begin the automation process, the source model is captured and held within DriveWorks – it’s important to note that although you are working with master data, DriveWorks takes a copy of that data so that the integrity of the master model is maintained.

Once the working model is defined, you then begin to grab dimensions and features from it to use as the basis for the automation. This is most likely to be named dimensions and parameters from the 3D model, but the truth is that DriveWorks has an incredible granular level of access to almost everything within a SolidWorks data-set, meaning it can be easily controlled at the required level of detail.

The next stage is to capture or add custom properties that will be either used as inputs to the design or driven by it. Drawings are next to be captured and it is good to see the level of thought that the team has put into creating an intuitive way of working with sheets, views, annotation text, annotation properties and layers. If you have well laid out drawings based on one model, the chances are they’ll transition well to another variant and 90% of this process can be automated.

The penultimate stage of data capture is to define any features, parts or sub-assemblies which might be swapped out – perhaps different product variants have different actuator sizes to handle greater loads, or maybe different electronics are required for different variants.

The final stage is to define the file format that the data should be translated to on completion, whether that’s a standard 3D CAD format, an eDrawing for sending to a customer, or a PDF.

Form and input design

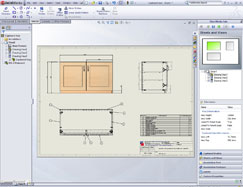

Now that’s the basics defined, the next step is to define how users will interact with the data and generate each design variant in practice. This is done using a fairly Windows-standard form creation tool, which gives control over the appearance, behaviour and layout of the form. It allows all the usual field types to be added, such as options, toggles, and drop down lists, as well as tools to add images, labels and guidance messages for users.

Defining the rules

Forms can incorporate many fields and controls including images to help the user make appropriate selections

The final stage is to define how those inputs interact with the data in the form of rules – and of course, the resultant outputs required. DriveWorks Solo has a very rich set of functionality for defining intelligence within a model. A nice touch is the pervasive search facility that allows users to find precise data and to filter out what’s not required. This pays huge dividends, as the potential parameters for a reasonably complex model can be vast (N.B. The DriveWorks team says that some customers have upwards of 14,000 potential rules and variables in some projects).

Some items are filled in automatically (such as file names) or you can dive in and do it manually. The good news is that the DriveWorks team has been working to make this very much a ‘grab, define and run’ type process for rules definition, using intelligence where needed and giving users access to the tools to do more complex work manually.

Tables for look up lists are a snap, allowing manual creation or copying and pasting from Excel to ensure that standard sizes and options are available.

Aside from the really comprehensive Help file and the ability to make comments on the rules – the how and why they are as they are – the Rules Builder also provides feedback as you build rules including a step by step breakdown of what the rule will evaluate to.

The result

Once a project has been set up, creating new variations is simply a matter of filling out the forms. Enter the criteria and hit preview and DriveWorks Solo creates the new variation in SolidWorks immediately showing the results of your work. Any changes can then be made, and the system will then preview again and again to ensure it works, live. Once you are happy with the result, the inputs are finalised to generate the required outputs, all with the correct file names and based on your rules.

A really neat feature is the fact that a DriveWorks Solo project can be deployed in a single file which means it can be passed to others really easily. It strikes me as being a great application for a roving engineer or sales person who wants to go off site with a laptop and configure new products with others.

Conclusion

Once the automation project has been completed new variations can be generated by filling out the requirements on a form

The main aim of any DriveWorks project is to give your team a set of tools that can drive variant-based designs of a product or sub-system in a very automated manner.

By removing a significant amount of time from your design processes and by automating routine tasks, this can give engineers and designers more time to work on more challenging problems, and to identify new areas for innovation to help push your products and your business forward.

But to achieve that, the system needs to be able to handle the definition of that automation environment, as well as being easy to use by a non-expert, rather than a costly consultant. By combining the power of its automation and its very deep knowledge of SolidWorks, the DriveWorks team has created a product that is not only easy to use in terms of creating variants through automation, but also to create the automation projects in the first place and maintain them on an on-going basis.

Automation can be a complex business, but the good news is that complexity is more likely to arise from your geometry and the intelligence you put into it, rather than the enabling automation, which is where you will find the benefits.

There’s been a concerted effort to make sure that the system works in the same way that SolidWorks does. Help is available directly within the interface giving good guidance and examples. Yes, the process requires some thought and planning to achieve a good automation level, but by providing good solid worked examples and pointing its users towards the best way to get something done, it should make it much easier to deploy on the first live project.

At the outset, I asked if DriveWorks can bring automation to the masses. The simple answer is no – automation is not for everyone. However, if your products are modular, designed to order and based on variants, then there is huge potential to transform your business. DriveWorks Solo is easy to use, easy to deploy and easy to adapt as your products change. The only question should be – if you have a need for design automation, why aren’t you using it already?

Getting started

DriveWorks Solo is available as a 30-day trial, downloadable from driveworks.co.uk While this isn’t particularly unique these days, it stands out due to the wide range of support tools that back it up.

On the website there are a number of resources to assist the user in getting up to speed with and proficient in the system. Online training is available in the form of traditional tutorials as well as video resources. There’s also a selection of templates and quick start content with industry-specific examples. These not only include worked examples in terms of geometry and rules capture, but also a further extension of that with templates for sales quotes and the like, all of which can be adapted to your own processes and business requirements.

| Product | DriveWorks Solo |

|---|---|

| Company name | DriveWorks |

| Price | £2,400 including first year subscription |