When Swift Group launched its compact crossover camping vehicle Basecamp, its intention was to bring to market a product notably different from the rest of its leisure-vehicle portfolio and with wide appeal for great-outdoors enthusiasts.

It’s been a good summer for UK-based caravan parks and campsites. With Covid-19 travel restrictions persuading British holidaymakers to take a break closer to home, demand for pitches has soared.

According to figures from tourist board Visit Britain, 16.4 million UK adults were intending to take a domestic getaway this summer. Of these, around one in three (or some 5.4 million) were planning on camping or caravanning.

If they develop a taste for this kind of ‘staycation’, that may in turn drive sales of new and used leisure vehicles – a category that includes caravans, motorhomes and park homes.

As early as mid-2020, for example, a survey from the National Caravan Council showed that registrations of touring caravans were up 20% year on year, and that 37% of them were made by first-time owners.

Against this promising backdrop, Swift Group – UK’s largest manufacturer of leisure vehicles – has high hopes for Basecamp, the compact crossover camping vehicle it launched in 2017.

When compared to more traditional touring caravans, there’s much about the design of Swift Basecamp that will recommend it to first-time caravan buyers, along with many other outdoor enthusiasts, too.

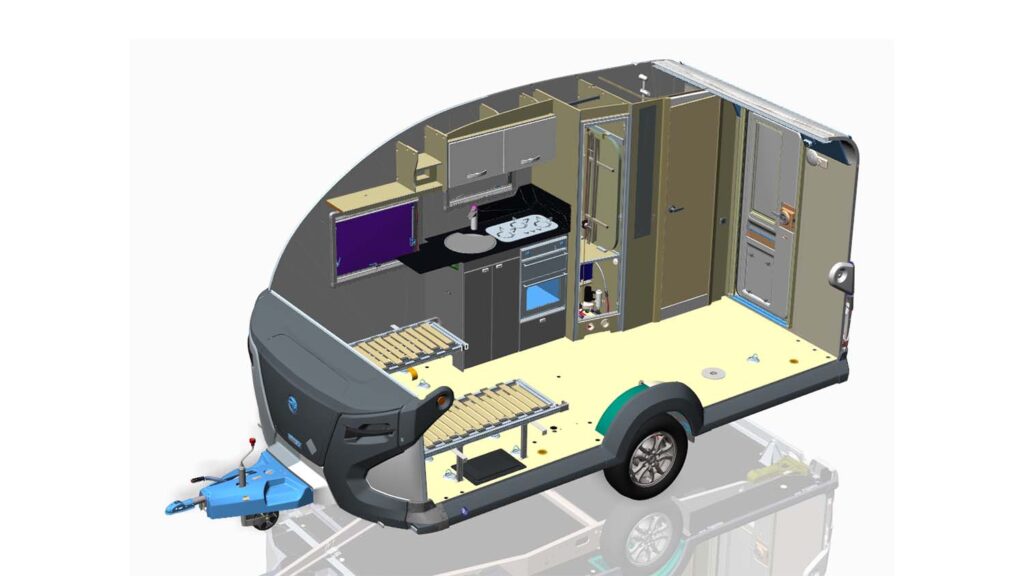

For a start, it’s lighter and more compact, making it easier for smaller cars to tow and easier to store when not in use. It offers high standards of comfort and convenience, with a well-equipped kitchen, cosy sleeping areas and clever storage solutions. And it’s flexible, with an inflatable awning that expands the available living space once owners have identified the perfect spot to pitch camp.

Finally, there’s the matter of relatively low cost: the retail price of a brand-new 2021 Basecamp is under £20,000 for a two-berth model and just over £21,000 for a four-berth model.

All of these features make Basecamp extremely accessible and appealing to a very wide cross-section of would-be caravan owners, says Chris Milburn of Swift Group. As the company’s head of design, he oversees a huge portfolio of caravans, motorhomes and holiday homes – but the intention for Basecamp from the very start was to do something different, he says.

“The key thing for us was to create something that could rekindle the love affair with the caravan, by building a product where the experience was halfway between caravanning and camping – something more than a basic camping experience,” he says.

“We wanted to create something that was quite unique in the marketplace, simple and easy to use – and I’m glad to say that we succeeded. But on top of that, Basecamp has a lot of character. It’s fun and funky, with real appeal for people who are young at heart and want something that fits their lifestyle, whether they’re into energetic pursuits like surfing or simply enjoy getting off the beaten track for a bit of downtime.”

From concept to manufacture

At Swift Group, the design of all products is handled by two distinct teams, following an approach typically seen in the automotive industry. Early concept development is carried out by the Advance Design Group, which then hands over to the Development Design Group, where concepts are built out as ready-for-manufacture 3D CAD models.

In the Advance Design Group, the main tools used are Alias and 3ds Max for modelling, and their associated rendering tools for visualisation. In the design of Basecamp, for example, Alias-based designs were visualised using Showcase, says Milburn, although today, the group uses VRED instead.

Once a high level of visualisation has been achieved, giving the Development Design Group a clear and in-depth idea of the look and feel required for the external shell and interior layouts, the baton is passed to that group, which carries out its work using PTC Creo.

“Creo is the backbone of our development work, to ensure that our visualisations are converted into something that’s fully engineered and fully production-ready,” says Milburn.

Swift is a long-term Creo user. The company first adopted the software in around 2004, when it was known as ProEngineer. From the start, it has relied on PTC partner Root Solutions for help and guidance in getting the most of the software – a very welcome resource, given the huge evolution the product had undergone over the last decade and a half, says Swift’s engineering director Paul Cunningham.

“If I think back to what the fidelity of our models was like back in 2004, compared to where they’re at today in terms of the level of detail we have, it’s pretty remarkable,” he says.

“To be fair, our models were always reasonably sophisticated by the standards of the day, but now, we get a great deal more functionality from Creo: simulation tools, piping and cabling, advanced assembly and so on. It’s been a pretty significant transition and it’s enabled us to reduce rework in our factory, check designs in more detail, and really take a thorough approach to ergonomics.”

Another big step forwards, he adds, has been the way that people from inside and outside the business now engage with 3D models created in Creo. Internal users that rely on them include senior decision-makers, members of the sales team, and employees from the factory floor.

External users are typically dealers, who can interrogate Creo Illustrate to identify exactly the part they need to fulfil an end-customer’s specific requirements, and then click through to an ordering system.

New trails to explore

That said, there are several new areas that Swift is now looking to explore and where it sees an opportunity for expanding its use of Creo. For a start, there’s a need for more advanced simulation; Swift has typically outsourced the computational fluid dynamics (CFD) work it needs to get the external shape and aerodynamics of caravans like Basecamp right. But PTC’s partnership with Ansys, and the two software companies’ work on embedding CFD into Creo with Creo Ansys Simulation and Creo Simulation Live could see Swift bring this work in-house in the future.

Then there’s the whole area of generative design. The rise of electric vehicles (EVs) means that a very different type of vehicle could be towing caravans in the future, with huge implications for caravan design. Here, Cunningham is already having discussions with Root Solutions, to see how Swift might explore Creo’s generative design capabilities to achieve an even lighter, more easy-to-tow product.

“We’re very excited about generative design,” he says. “One thing we’re talking about all the time right now is making sure that we get the future marriage between EVs and caravans exactly right, so that the two are compatible for the long term. And that, for us, is going to involve some serious lightweighting in our design process,” he explains.

“If you look at the current capabilities of battery-powered EVs and where they’re going in future, we know we need to shed some serious weight from our caravans – in the region of hundreds of kilograms, in some cases. And we need to start taking steps towards that now, which is where I see a big role for generative design, in exploring the options available to us to make progress in weight reduction,” he continues.

Ready for manufacture

When all caravans, motorhomes and holiday homes are taken into account, Swift typically manufactures between 13,000 and 14,000 units each year – and the vast majority of that work is carried out on the company’s 100-acre site at Cottingham, near Hull.

As Chris Milburn puts it: “We’re very definitely not an assembly shop. We’ve got a huge manufacturing capability on-site, covering composites, timber machining, panel lamination. Pretty much most of the major component subsystems going into completed vehicles are created here from raw materials that we buy in.”

There’s plenty of overlap, of course, between the components and subsystems that go into different products, and vehicle models are frequently updated and refreshed. To tackle the product lifecycle management (PLM) challenge that this presents, Swift uses PTC Windchill. This provides a single point of reference for all of the components and parts that make up each model. Says Paul Cunningham: “This is how we ensure that we’re reusing as many common parts as possible across our portfolio and not duplicating the effort that goes into designing and engineering similar components.”

A number of critical back-end IT systems at the company are integrated with Windchill, he explains, so that decision-makers around the business can be confident they are working with the right data when it comes to procuring raw materials, planning production schedules, managing inventory and so on.

Future direction

So what’s next for Swift and for Basecamp? For now, there’s no radical redesign on the cards, says Milburn. “We’ve gathered quite a devout following for this little product. People stick their names on the side of their Basecamp. They join the Facebook Swift Basecamp Owners group. They cherish the product, which is really nice to see. There’s a real fondness for the way it looks and feels and, as a result, it’s managed to weather the years since it was launched with very little needed in the way of major changes.”

That said, the design continues to evolve with small tweaks, often based on feedback from owners – a basic rule that applies right across the company’s vast portfolio and a perpetual challenge for the design and engineering teams.

“There’s a lot going on right now in the market, and of course, we have a lot of discussions about our product strategy and where the market is headed,” says Milburn. “But one thing hasn’t changed at all: the need to constantly update products. Everything needs refreshing, all the time – because that’s what the modern market demands. And it’s something we take very seriously, because it’s what has kept customers coming back to us, again and again, for decades.”