To get some insight into the newly launched Creo 11 and where the software is pushing workflows most in this release, DEVELOP3D spoke to Paul Sagar, VP CAD product management at PTC to get his views on the important features in new release and to get a sense of where the CAD software is heading

___

D3D:

– A good place to start is how does Creo 11 stack-up against the last few releases we’ve seen?

Paul Sagar:

It’s a big one for new features and updates: Creo 11 has over 150 enhancements in this release – that’s a pretty significant chunk!

For reference, I think that in Creo 9 we added about 120. In Creo 10, it was somewhere around 130.

A lot of those 150 are really customer driven, based upon feedback we’ve had talking with our customers.

Some of those are relatively small improvements and tweaks – we’re always looking to make the product easier to use and improve general features like core modelling and general assembly work – but others are pretty significant.

– There are some strong updates for composites design in the new release. Given the tools were only added in Creo 10, how far have they developed in the past year and what’s guiding the direction PTC is taking with them?

We’ve gone out to all different markets – not just ‘big aerospace’ – and asked them about what they need. We work closely with customers that build boats, bicycles, race cars, wind turbines and, of course, aeroplanes. We got a very large group of these customers together and went through all their requirements.

Some of these overlap, some of them are unique to certain industries. And what we’ve done is taken those capabilities and put them into the product.

With Creo 11 we’ve tried not to focus too much on a specific industry, because what we want to do is make sure our solution is broadly applicable to all industries, so we looked at three main areas.

The first was to expand on what we did in Creo 10 and streamline the UX for that, and then we’ve introduced the notion of Zones and of Zone Stacks. Zones allows really big models made up of hundreds or thousands of composite plys to be broken down into sections and really investigated.

With Zone Stacks, you can apply your ply stacks to the individual zones. So it’s a much faster way of building a large number of ply stacks very, very quickly.

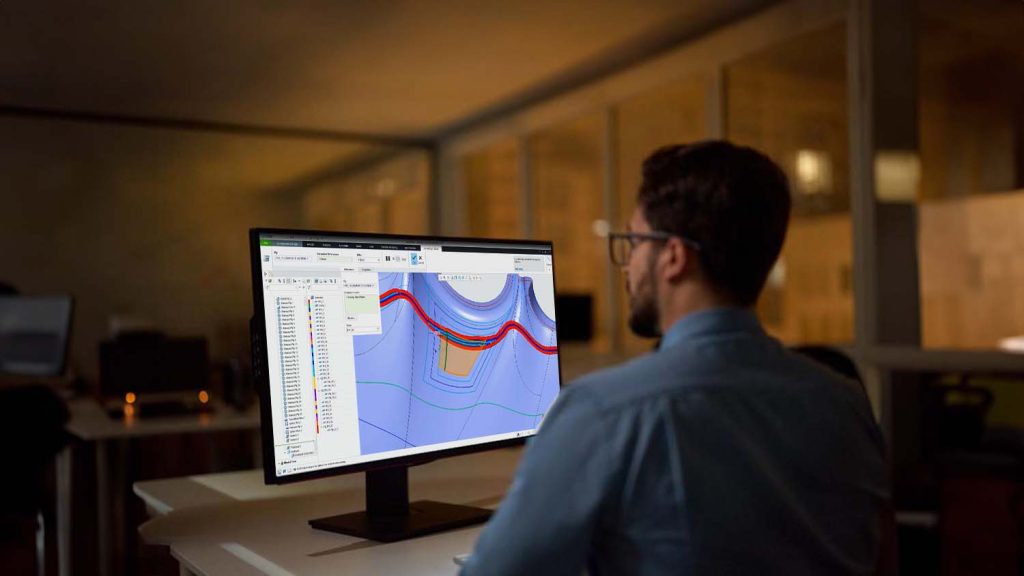

We’re also focused on the downstream manufacturing of composites, not just the designer’s finished ply structure, so there are tools for improved draping, extension of boundaries and creating laser projection files using LAP and Virtek systems.

– Model Based Design (MBD) has continued to grow in importance over past releases, helping communicate critical model information to stakeholders. How is it shaping up in Creo 11?

The whole MBD initiative really falls into a couple of categories: efficiency – reducing the inordinate amount of time it takes documenting 2D drawings – and removing misinterpretation.

Because MBD is all controlled by the 3D model with all its semantic awareness, the system can guide you. So, as long as the user has defined those critical elements, there’s never a risk of something being missed.

This release brings tables to the fore. In a 2D drawing there’s typically lots of tables that support a number of different things. Although, once you hand that drawing to somebody else, you’re breaking the chain of the digital thread – that 2D drawing might be out of date, right?

So in Creo 11 there’s a full semantic relationship between the table and the 3D model, and if you do a query on the table, it will highlight on your 3D model exactly what that is referring to. It feeds the traceability of your designs.

We’ve also expanded our GD&T advisor capabilities in Creo, to help guide the user through adding GD&T onto their model and validate that the model conforms to the appropriate standards.

– The partnership with Ansys for simulation tools as part of Creo continues with the new release, how has that evolved?

There’s a lot of new abilities across both Creo Simulation Live, our real time simulation capability, and in Creo Ansys Simulation, the more traditional higher fidelity simulation.

A nice new feature in Live is its ability to predict the heat transfer between solids and fluid flow (excellent for predicting heatsink abilities early on), as well as being updated to the latest solvers from Ansys.

For Creo Ansys Simulation I’d highlight the new Transient Structure ability, which allows users to understand the impact on the structural integrity of your part over time.

From a generative design perspective, there are three main improvements: the introduction of a minimum thickness control to control the amount of ribbing on a part, for example; there’s added support for bearing, so now you can specify that as an input for your optimisation, and finally –when we reconstruct a shape as full B-Rep geometry, there’sthe ability to take into account if there was planar symmetry.

– There are some interesting new tools for additive processes in there, especially around lattices. Is this something you’re seeing customers adopt more?

Lattices now are starting to be used more as part of the design process – so they actually have a purpose, they’re not there to lightweight a design – and we have tools in there to be able to simulate and optimise those designs.

What we’re seeing is customers rethinking the design process and what they can do to take advantage of lattices – things like impact absorption, or gyroid lattices for more efficient heat exchangers built as a single part.

A key new feature in Creo 11 for lattices is its ability to connect multiple, disconnected volumes of beam based lattices with a seamless flow that joins them.

– High-speed machining features high-up in Creo 11 release notes – how do you see user requirements evolving with regards to machining?

We’ve been heavily investing in expanding our subtractive manufacturing capabilities, and what we’re seeing is a shift that now everybody is interested in high-speed machining. Just the little tweaks that it allows you to make – taking a couple of seconds off a toolpath when you’re making that toolpath 1,000 times a day – it all adds up.

With this release we’ve started to shift some focus towards turning, expanding and modernising some of our capabilities for four-axis turning. A lot of the work we’ve done around machining is focused on customer needs and driven by type of interactions we have with them for what they need, based upon the latest innovations in manufacturing.

– What’s the part of Creo 11 that you think will get the most attention?

Probably the one that will get the most love, based on the positive beta testing feedback we’ve had, is the addition of multiple sheet metal bodies.

Back in Creo 7, we introduced Multibody Design capabilities where you could build a model that had multiple solid bodies in it. What we’ve done in 11 is expand that, so you can do that with multiple sheet metal bodies – users can now have a part that has multiple solid bodies and multiple sheet metal bodies in it as well. It spans the use case for looking to build multi thickness sheet metal parts, or the same thickness sheet metal parts, and it just expands the usability and simplicity of building those parts.

– What’s the part of Creo 11 that excites you most?

I would say it’s the composites! It’s only 12 months-old but the breadth of capability we now have for composites is something I’m very, very proud of because in one and-a-half releases we’ve gone from having no solution to having an offering that I would say competes head on with the other composite software out there in the market.

Typically, if you’re introducing a new product, it’s going to take you two, three, four, maybe even five releases before you get to a point of being a leader in that space. So, to be up there with the other leaders so quickly, I think is pretty impressive.

– And finally, we can’t leave without mentioning Creo+. When can we expect all the new features of Creo 11 to appear in the SaaS version?

All of these new capabilities in Creo 11 will be automatically pushed out to our Creo+ customers around a month or so after the launch. As well as these latest capabilities, there are a few other improvements that we’ve made that are specific to Creo+ as well.

__

Paul Sagar is the vice president of product management, responsible for the CAD Product Management team. In his current position, he is responsible for understanding broad customer requirements for all of Creo, Creo Elements Direct, and Mathcad, developing short and long-range product release plans and communicating those plans across PTC’s development organisation.

Paul Sagar is the vice president of product management, responsible for the CAD Product Management team. In his current position, he is responsible for understanding broad customer requirements for all of Creo, Creo Elements Direct, and Mathcad, developing short and long-range product release plans and communicating those plans across PTC’s development organisation.