Here, Hyperganic CEO Lin Kayser gives his view on additive manufacturing in mass production, and how he believes Digital Physical Products – conceived, assembled and traded digitally until, at the last mile, they are produced as a physical object – will foster global collaboration, shorten supply chains and jumpstart innovation

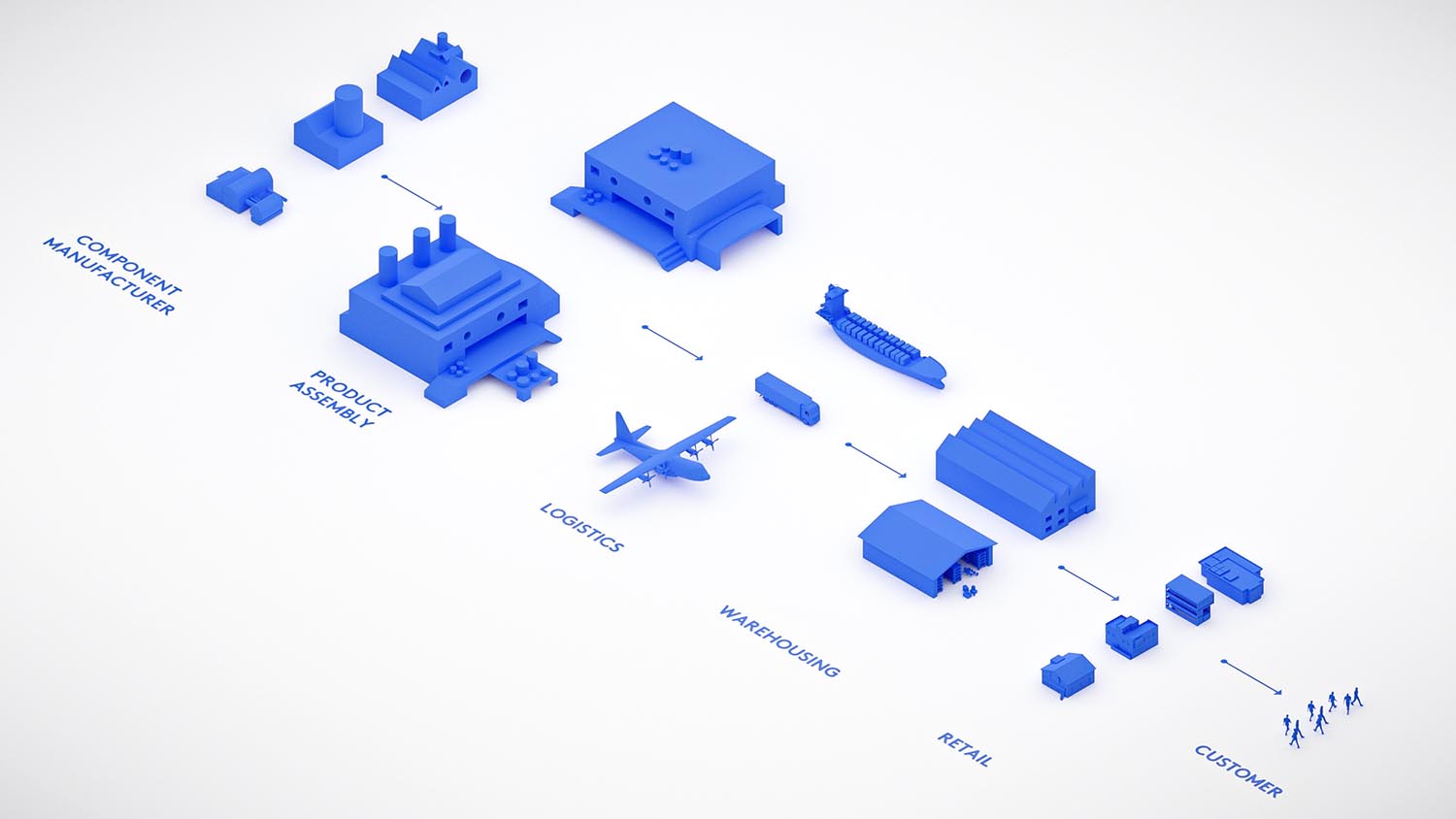

In trade and manufacturing, we usually think about traditional products in physical form.

These products are assembled from a multitude parts. Parts which are produced in factories all over the world, then shipped to another factory, assembled into components, probably shipped to yet another factory, until the final product is ready.

This product is then shipped again, usually to an intermediate warehouse, from which it is then distributed to physical shops or online retailers where the end user can buy them.

This is complicated and it takes time. It’s hard to scale, and to make a product globally available is a complex undertaking. Innovation is slow, because all the physical parts actually have to play together. Setting up the supply chain for a changed design is far from trivial.

On the other hand, there are also purely digital products – intangible assets, like music, images, videos, software.

They are often sold just like physical assets, but other interesting new business models are possible: renting, streaming, usage-based tiered pricing.

Digital products scale infinitely and are instantly globally available. Innovation and iteration are quick and easy.

Digital Physical Products

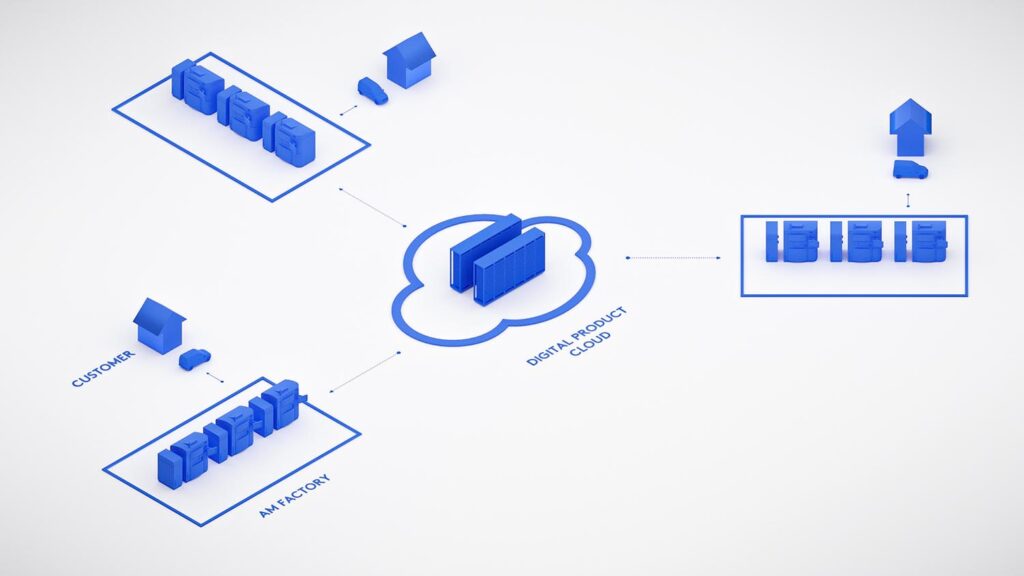

The advent of AM mass production enables a new hybrid type of products. I call them Digital Physical Products (DPP).

A DPP is a physical product, a tangible object — but it is conceived, traded and shipped in digital form. At the last mile it is transformed into a physical product. Only late, shortly before it ends up in the hands of the customer, is it actually manufactured.

Digital Physical Objects enable true digital supply chains. Instead of shipping physical parts, digital components are assembled virtually.

These components are more than static representations of a part. They can be smart and dynamic, driven by algorithms: they can adapt to the role they play in a product. They are context sensitive. As a result, the entire object can be globally optimised for each use case. Products can be customised to each end use and for each end user.

Smart and dynamic, driven by algorithms: they can adapt to the role they play in a product

The DPP economy enables new business models for the participation of all stakeholders. Pricing can be flexible, depending on each component’s contribution to the final object.

In a physical parts economy, there are cheap parts and expensive parts. Expensive parts usually have a more complex design, whereas cheap parts have to be simple. Since in traditional engineering complex parts cost more to produce, this approach made sense in the past.

Accelerating Innovation

In mass production using 3D printers, complexity does not drive cost. An AM factory can always spit out the most advanced and optimised object. Once you have found a way to create a better part, it makes no sense to continue the old one.

So, in a DPP economy, you always choose the best possible solution. As a result, ideas and best practices spread much quicker. Physical objects are finally engineered at the speed of Moore’s Law. We replace the slow traditional trade of physical objects with a rapid exchange of ideas and a race to the top.

As an engineer, you can now focus on creating an optimal product. A lot of our time today is wasted re-engineering things for different use cases, often trying to drive down cost and complexity.

How would your approach to product design change, if you could perfect one idea and make it instantly available for use in all products that require it?

What if you, as a product designer, could always pick from a global pool of solutions, all of which are up-to-date? It may sound far-fetched today, but this is quite common in the world of software, so why should it not apply to hardware?

Now is the time to move engineering and manufacturing to this new paradigm. Through global digital collaboration and automated local production we will accelerate innovation and overcome arbitrary trade barriers – all of which is essential to solve some of the global challenges of our time.

Lin Kayser is the co-founder and CEO of Hyperganic.

Lin Kayser is the co-founder and CEO of Hyperganic.

The Hyperganic software platform enables an engineering paradigm, where objects and entire products are designed by computer algorithms and AI and manufactured using additive manufacturing.

Kayser has a 25-year entrepreneurial track record, disrupting industries as diverse as industrial automation and Hollywood cinema technology.