Brian Thompson, CAD division VP and general manager at PTC, examines how Covid-19 has accelerated the popularity of CAD design in the manufacturing world and why digital transformation continues to hold the key to unlocking its true potential.

The power of design has never been more important. As the UK economy emerges from the shackles of the pandemic, manufacturers are trying to find new ways to bring products to the market and, whilst speed is always of the essence, there is an increasing need to minimise costs in the development stage.

For this reason, we are witnessing a surge in CAD adoption.

Clients across aerospace, automotive, defence and renewables are all investing in the latest software solutions, such as Creo, and yet there are still many questions doing the rounds about how to maximise its true value.

The answer lies in digital transformation. I realise this phrase has become somewhat of a cliché, but the fact is that customers have digital transformation initiatives across the board and transformation is happening.

Nobody is sitting around having coffee and discussing it. Clients are putting energy and money behind these initiatives.

Manufacturers want to be far more model-based in everything they do, and not only in product design and product development.

To see this, it is important to remember what Model-based Definition (MBD) is: it is an approach to creating 3D CAD models so that they effectively contain all the data needed to define a product.

That has two big implications.

Firstly, the 3D model is the source authority for everyone and drives all engineering activities because the information is placed directly on the geometry, which means you can say goodbye to chasing outdated, ever-changing 2D models around the company.

Secondly, important complementary processes, such as simulation or preparing models for manufacturing, run off that model.

Here’s what we’re also seeing in terms of market requirements. Customers are looking for technologies that help them get as far as they can in the digital environment before they commit to money, time, and togetherness in the lab developing prototypes.

It’s not just about Covid, it’s about costs. Our partner, Ansys, a world leader in simulation, did research showing that upwards of 70% of product cost was already baked into the product by the time development reached the prototype stage.

70 per cent! By the time you reach that number, any other changes you might make will only be able to have an impact on the margins.

Manufacturers, who are doing as much as possible digitally, are looking at simulation and generative design. And I don’t think it’s any secret why they do.

With simulation, designers can experiment in real-time, change their minds, change materials and approaches, all without spending a single penny on materials or lab time until they need to.

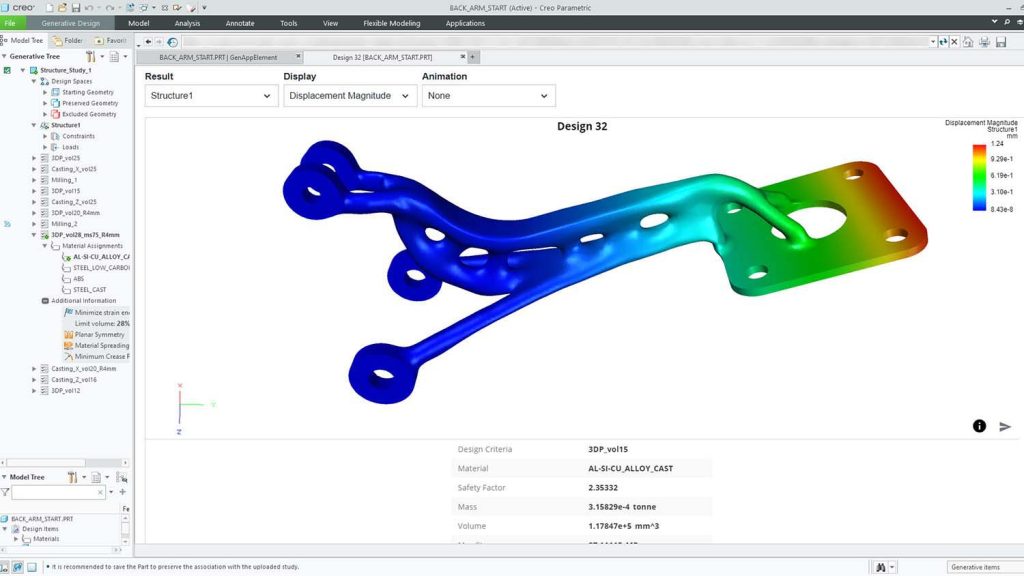

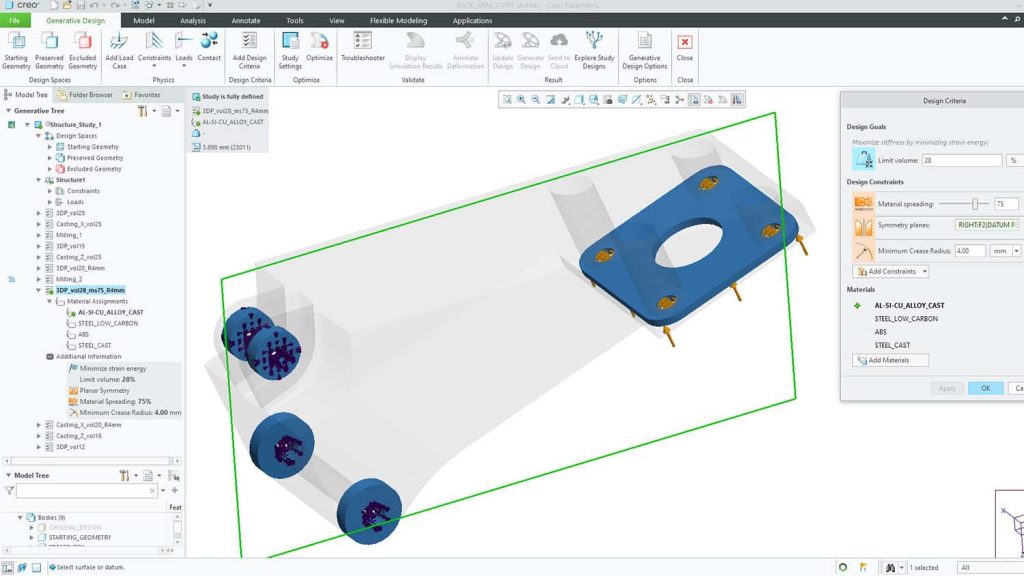

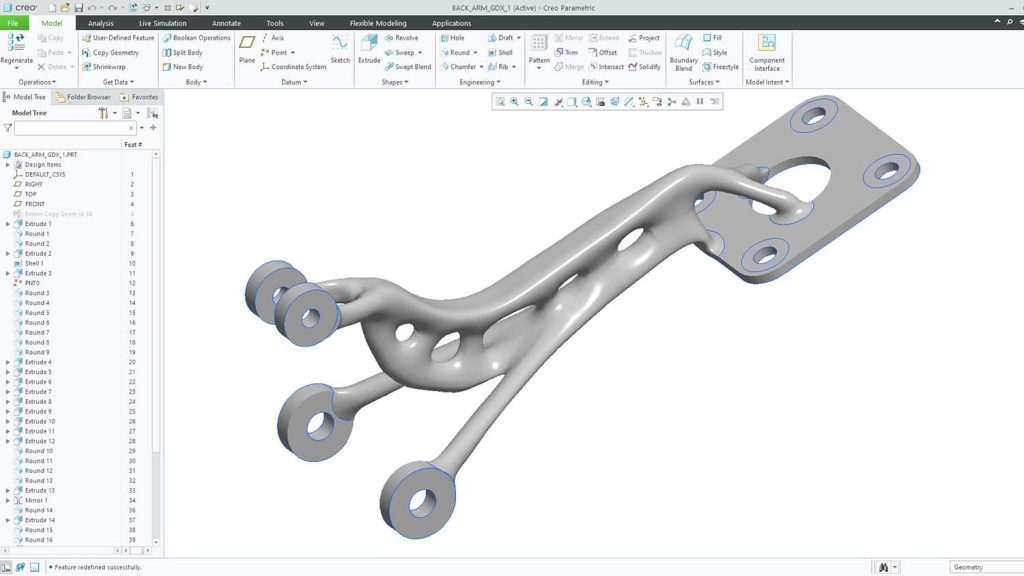

Generative design takes this a step further. We’ve seen customers like Jacobs Engineering and Volvo Trucks use this with great success.

The computing power is in the cloud, so engineers set the problem, the system creates and ranks alternatives, and engineers can use a solution as it is, or continue to evolve it on their own.

The Next Steps

Design engineers need to embrace digital. Full stop.

Simulation and generative design technologies will become more important. This is because these technologies allow design engineers to do what they went into the field to do: design great products!

I have yet to meet a design engineer who says: “What I really want to do is spend more time preparing my model for analysis only to find out I made an avoidable mistake at the beginning.”

Let me tell you: analysts feel the same way. They want to spend their time on problems that require their special expertise. I’d tell designers to brush up on topics like stress, strain, heat transfer, structural analysis and all they need these tools most effectively.

Model-based Definition will also continue to increase in importance and is not simply a clerical shortcut. MBD is about expanding the influence of the CAD model up and down the value chain.

This means the CEO is using a viewer to look at the model, the manufacturing engineer is running tool paths off that same model, and the design engineer is using that same model for simulation.

If you move even higher, MBD is foundational because it’s part of customers’ model-based enterprise strategy and, in turn, part of their digital transformation strategy. Both users and companies can start to open up a new world and it’s incredibly exciting to be part of it.

Firms can start on their own journeys and see benefits no matter the size of their business. People don’t have to boil the ocean, build spaceships in their bathrooms or have miraculous insights at 3am to enjoy the benefits of digital transformation.

The past two years have taught us that trying to make predictions is not worth the effort, but I can say we’re hopeful about how CAD and digital transformation can help our customers, and the businesses they serve in turn, to be productive and safe.

Brian Thompson leads PTC’s CAD and engineering calculation businesses as division vice president and general manager. Thompson is the primary spokesperson for Creo and PTC’s CAD Business.

Brian Thompson leads PTC’s CAD and engineering calculation businesses as division vice president and general manager. Thompson is the primary spokesperson for Creo and PTC’s CAD Business.

Prior to PTC, Thompson worked for more than 15 years in electro-mechanical product development in a variety of discrete manufacturing industries. He holds six product design patents, many of which are on products still being sold today.

He has worked in a variety of roles representative of PTC’s customer base such as funtional engeneering manager, product development, management and technocal product manager. Thompson holds a B.S. in mechanical engeenering and a M.S. in computer science from Renseelaer Polytechnic Institute in Troy, NY.