A new approach to vehicle development is necessary, says Nand Kochhar VP of automotive and transportation industry strategy for Siemens Digital Industries Software. Autonomous vehicles must embrace digitalisation and break down boundaries that often exist between engineering, product development and manufacturing

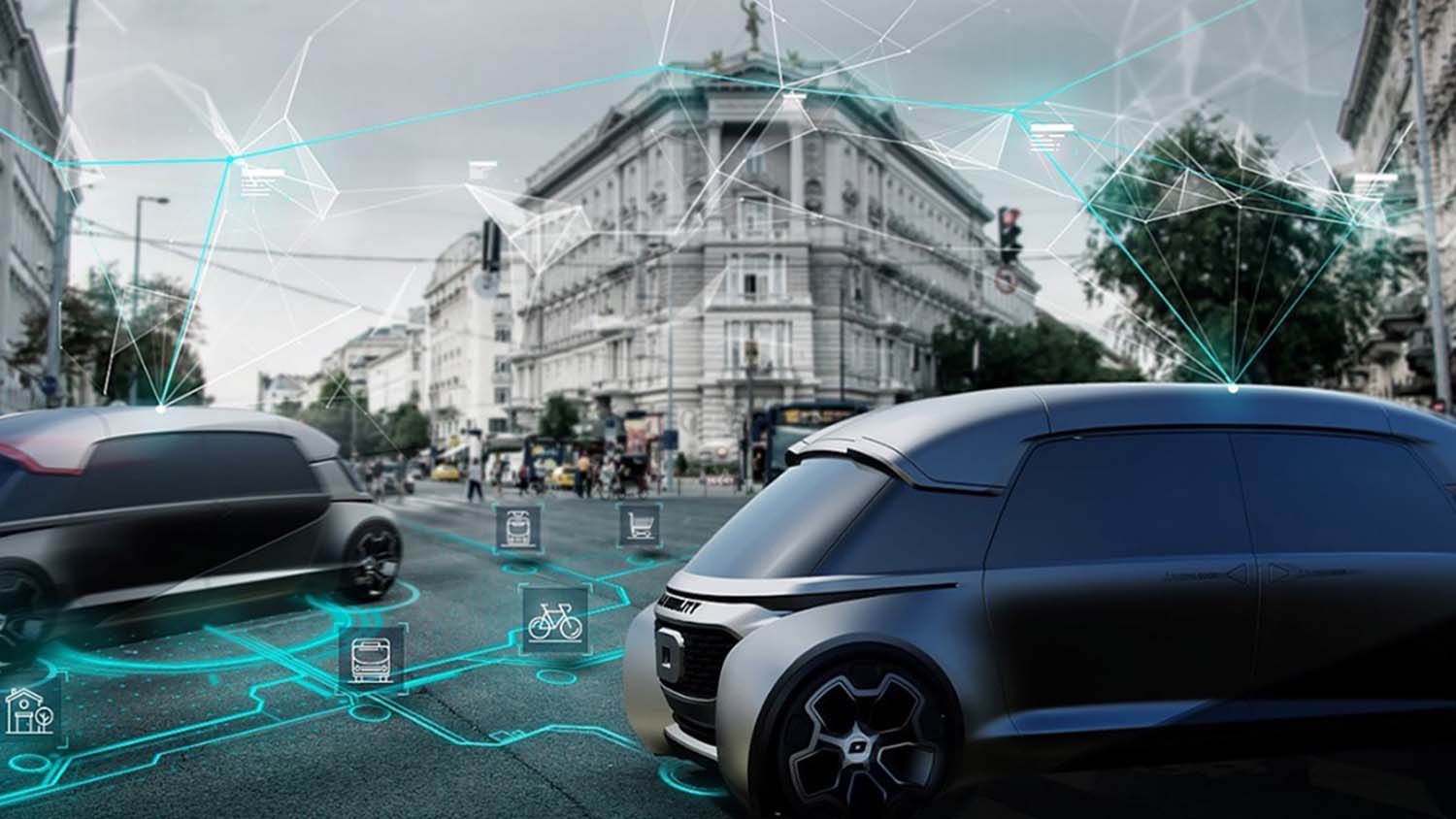

A mobility transformation is taking shape across multiple industries, including automotive and transportation. This shift is a combination of technological, regulatory, and societal changes pushing for greater safety, sustainability, and equity in human mobility.

In the automotive industry, this transformation has manifested in the immediate push for vehicle electrification, and the continuing development of automated and autonomous vehicle (AV) technology. In this piece, I’d like to take a brief look at the potential social and business impacts of autonomous vehicles.

The idea of a car that can drive completely on its own, with no human input, is compelling. For me, automated vehicle technologies have been a part of much of my career in the automotive industry, beginning with early development work on advanced driver assistance systems (ADAS), self-parking, and other such systems. As the technology continues to improve, both in terms of the vehicle technology and the digitalisation of development processes, it stands to revolutionise how we interact with vehicles and move about our world.

From the standpoint of a business transformation, autonomy promises to be a foundational change in the automotive and transportation industry. First, AVs will change the nature of automotive products, from essentially mechanical ones to integrated multi-domain technology products. This is because AVs will rely on a mixture of more traditional mechanical systems (such as braking and steering) in concert with advanced software and electronics to enable sense-think-act functions. For AV manufacturers, this translates to a shift in value, and thus their development priorities, towards the onboard electronics and software.

As the levels of autonomy approach SAE level 5, the disruption will only grow. Many experts expect that connected, self-driving vehicle technologies will also drive changes in the way that consumers use or access private mobility, tending towards a model of transportation-as-a-service (TaaS).

The fundamental idea behind TaaS is that most consumers will cease to own personal vehicles. Instead, TaaS customers will hail rides as needed from a fleet of vehicles owned and operated by a transportation company. This absolves the consumer from costs relating to vehicle maintenance, insurance, and fuel, while also allowing each vehicle to spend more time moving people about their environments.

The realisation of a true TaaS system will be a significant societal shift, as well as a dramatic departure from traditional automotive business models. Key benefits include safer roads, less congestion, reduced cost from vehicle ownership and the convenience of automated chauffeurs that can bring us from destination to destination. And it is this last point that is, for me, perhaps most exciting of all.

AVs and TaaS models should, if done correctly, offer broader access to high-quality mobility, enabling more people to access the freedom of personal transportation.

The question for today is how to continue to advance AV technology to realise the potential described above. Technologically, the most significant remaining challenge is the training of autonomous driving algorithms to perceive and interpret the driving environment, with particular emphasis on so-called ‘edge-cases’.

In addition, the development of a robust system of sensors, actuators, and computing devices that can perceive and respond to stimuli in mere fractions of a second will continue to be a challenge for the engineers working on AV systems.

Ultimately, there is no simple answer to this question. In our estimation, however, the development of true self-driving vehicles will depend on an integrated and closed-loop development process, built around a comprehensive digital twin, that incorporates advanced simulation solutions.

The comprehensive digital twin will serve as the foundation for a connected, cross-domain product development process, enabling engineers to develop and integrate the many complex systems that will make up an AV more quickly and with fewer errors.

This may include the placement and integration of sensors around the vehicle, the number and locations of computing devices, and the packaging of each system into the vehicle body. As vehicles become more sophisticated, AVs in particular, the simulation will become a necessary complement to real-world testing.

Simulation can help train the decision algorithms that will guide an AV and test the various electromechanical or mechatronic sub-systems much more quickly and efficiently than real-world testing miles. Some real-world testing will always be required, especially for certification purposes, but a combined approach will enable AV engineering teams to investigate and account for exceptional on-road scenarios more effectively, thus improving the safety of their AV systems.

The next step towards full vehicle autonomy will certainly be challenging. Part of the problem is the vast complexity inherent to nearly every aspect of AV development. The other part is that traditional product development methodologies have fundamental shortcomings when dealing with such complexity.

A new approach to vehicle development is necessary. AV manufacturers must embrace digitalisation and break down the boundaries that often exist between engineering domains and the stages of product development and manufacturing. The key to this approach is a comprehensive digital twin that captures every aspect of the vehicle design and production.

Using such a digital twin, AV manufacturers can connect engineering teams from across the electrical, electronic, software and mechanical domains. This means AV manufacturers will be able to design, verify and validate entire AV platforms, ensuring the highest standards of safety, reliability, and passenger comfort.

About the Author:

Nand Kochhar is the vice president of Automotive and Transportation Industry Strategy for Siemens Digital Industries Software. He joined Siemens in 2020 after nearly 30 years with Ford Motor Company, where he most recently served as Global Safety Systems Chief Engineer. He also served as Executive Technical Leader, CAE, and as a member of Ford’s Technology Advisory Board.