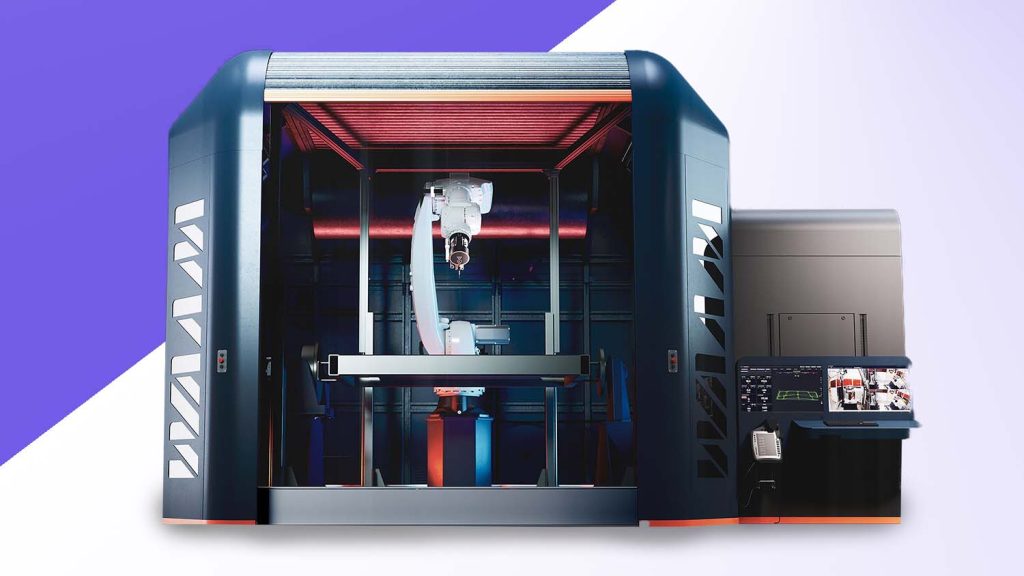

WAAM3D has launched its new RoboWAAM system, complete with sensing hardware and proprietary software, for large-scale Direct Energy Deposition metals 3D printing.

A start-up our of Cranfield University, WAAM3D has been pioneering research and development in the field of Wire Arc Additive Manufacturing (WAAM) since 2006, and 80% of the components used in its latest system have been developed in-house from scratch to create a coherent hardware and software ecosystem.

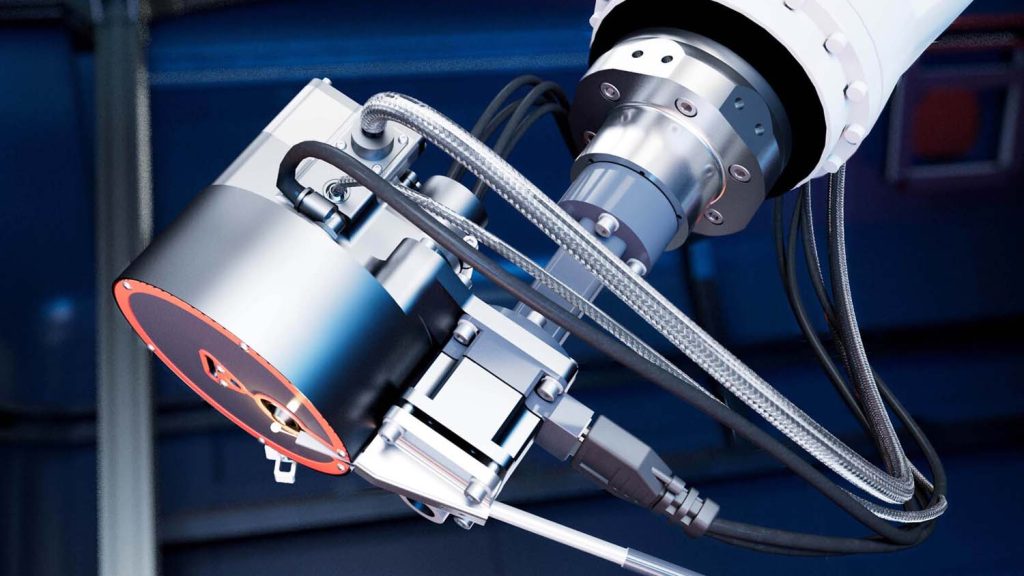

Much of the technology is focused on the bespoke end-effectors that control the wire flow and using sensors and advanced process intelligence can feed back build data throughout the process.

Onboard is WAAM3D’s ShapeTech interferometric sensor that reconstructs the 3D profile of the deposited structure in realtime, extracting the layer height value all around the component.

This can help validate the consistency of deposition and in the achievement of key geometrical targets while printing is in progress, a process that WAAM3D says can eliminate the need for lengthy laser scans or touch-probe quality checks during the build.

WAAM3D’s software and operating system oversees the whole build process, providing process monitoring and governance over health and safety capabilities, as well as a fully auditable process trail.

Designed as a standalone plug-and-play installation, with full health and safety compliance for the shop floor, the RoboWAAM casing structure housing the robotic arm acts not only as a barrier cage, but also helps control the build environment temperature and removes fume emissions. A bulk wire storage and large spool capability of 70 kg, aids longer uptimes and reduced operator intervention.

WAAM3D CEO Filomeno Martina, said: “With the launch of RoboWAAM, we have taken the production of large format 3D metal additive printing to the next level. RoboWAAM is capable of processing virtually any material available in the form of wire and it has a maximum build envelope of 2m x 2m x 2m.

“This makes it the ideal 3D printing option for new as well as repaired metal components that require high structural integrity, cost-effectively.”