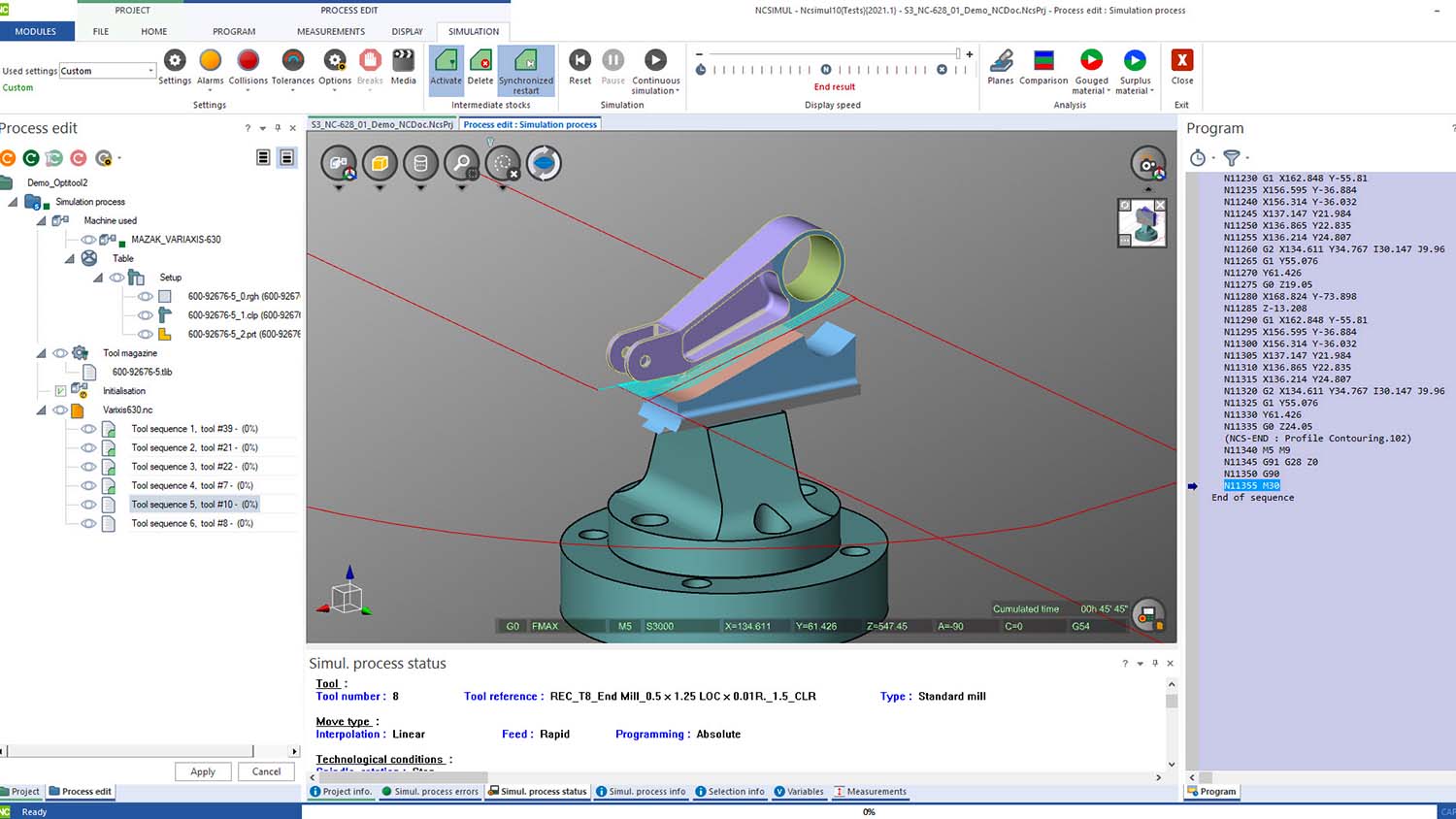

Hexagon’s CNC machining simulation software NCSIMUL is looking to help manufacturers avoid notorious 5-axis singularity and improve the quality of complex parts.

When the CNC toolpath generated by CAM software passes through, or near to, the singularity point, the machine tool can behave erratically – causing vibrations that result in ‘chatter marks’ on the component being machined, knackering the quality of the surface finish.

The new release form NCSIMUL helps by predicting the lines of code where there may be problems with vibrations and surface quality, programs can be improved by modifying cutting strategy parameters or changing strategies altogether.

Hexagon states that it also helps manufacturers optimise the stock position and orientation, which affect the achievable cutting feed rate of 5-axis continuous trajectories, leading to cutting factors that can differ significantly from the CAM program for a given machine.

Hexagon states that it also helps manufacturers optimise the stock position and orientation, which affect the achievable cutting feed rate of 5-axis continuous trajectories, leading to cutting factors that can differ significantly from the CAM program for a given machine.

“Singularity point analysis makes it possible to achieve the required surface quality for complex parts virtually, before going to the shop floor to cut the first part,” said Philippe Legoupi, product owner at Hexagon’s Manufacturing Intelligence division.

“NCSIMUL also now simulates the performance of the target machine to evaluate when the 5-axis cutting factor is close to 100 per cent, so that users can modify the stock orientation and position to achieve the desired feed rate.

“Armed with these two capabilities, manufacturers can now decrease 5-axis cycle times and achieve consistent quality for any part.”

A new material-specific optimisation tool, Optipower, was introduced in 2019 to optimise the program and limit the power necessary to remove material. In NCSIMUL 2021.1, Optipower is now able to calculate the cutting force applied to the tool’s external contact point, ensuring the maximum force of the tool is not exceeded, specifically for the tangential cutting force.

“We’re working to make manufacturing smarter through better use of simulation data,” explains Legoupi, “The maximum torque and cutting force for each machining sequence are integrated into the analysis report, and progress can be monitored with a force-time graph visualisation.”

The latest release allows data to be sent from the user’s CAM system to NCSIMUL 2021.1 without any adjustment before launching verification, meaning NC-programmers can start debugging the G-code file during programming, and go back and forth between CAM and simulation.

Furthermore, a new intermediate stock management functionality ensures the simulation will always start from the last updated intermediate, saving potentially hours of simulation time.

When loading a new version of the G-code file, NCSIMUL automatically stores the previous file, and compares both records at the end of decoding.