Velo3D Flow 3.0 software has launched, adding new features for users of its Sapphire family of metal 3D printers to support the print preparation of larger parts.

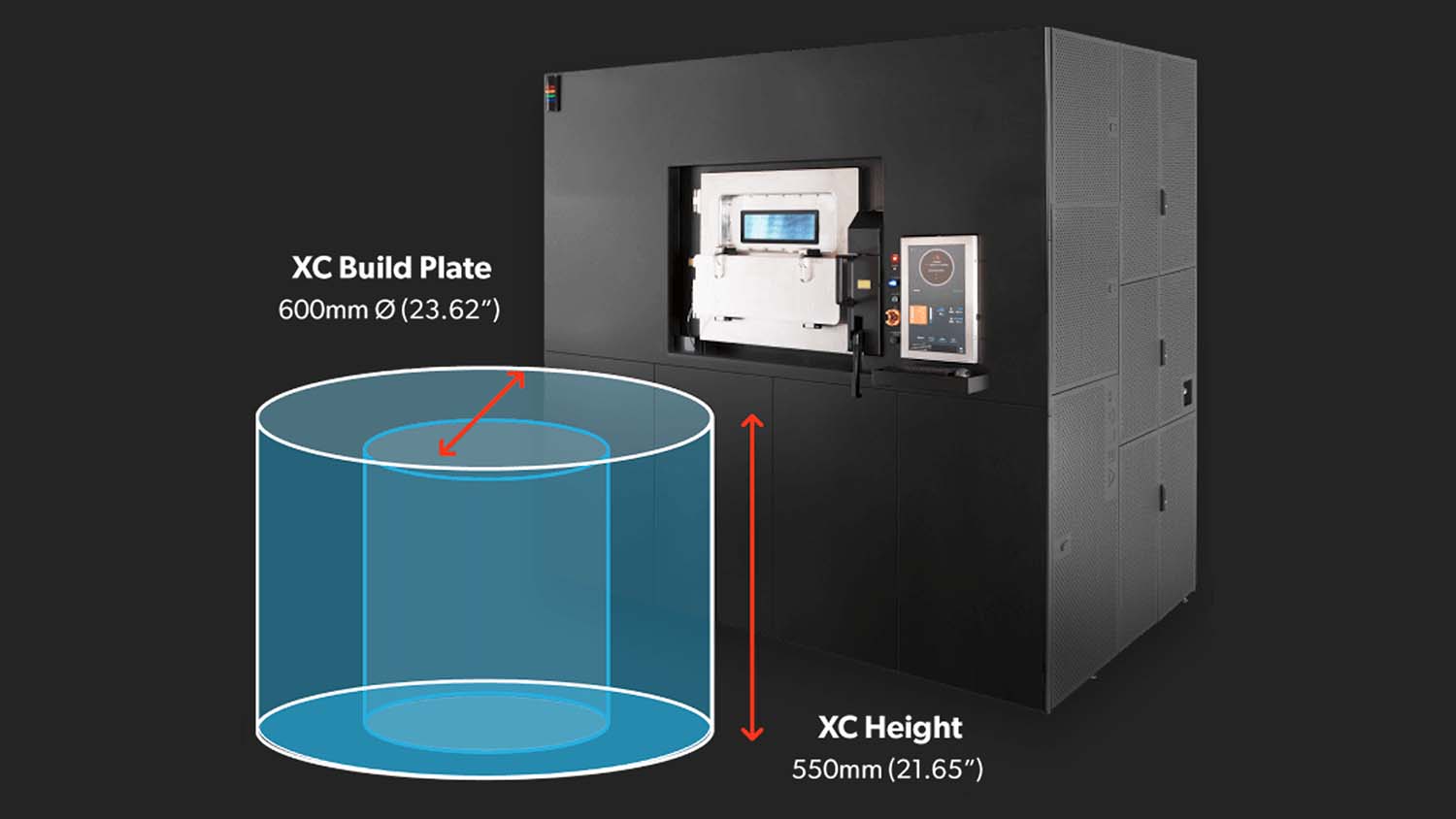

The new version supports larger models of parts that are able to be manufactured on the company’s Sapphire XC (Extra Capacity) printer, which can produce parts that are up to 400% larger than the standard Sapphire printer.

Flow 3.0 also supports the scheduling of additional lasers to maximise the efficiency of the Sapphire XC’s 8 1,000W lasers and increase productivity by up to five-times compared to the standard Sapphire printer.

Velo3D states that its Flow 3.0 print preparation software is unique in that enables users to upload a traditional CAD file of a part they want to print, ‘rather than having to spend additional resources designing the part for additive manufacturing’ and the need for part orientation and support structures.

Flow 3.0 accomplishes this by utilising a generalised set of recipes to precisely prescribe and simulate the layer-by-layer build for the desired part. The software’s composer detects geometric features and applies the corresponding process to achieve that desired outcome.

Velo3D says that unlike other software offerings, Flow 3.0 uses information from previous layers to inform the print strategy for subsequent layers, resulting in better parts and greater design freedom.

“When we are building new features into Flow we aim to simplify the experience for engineers who want to create parts using our additive manufacturing technology,” said Velo3D senior software engineer Victorien Menier.

“Our team is extremely proud of all that Flow 3.0 has achieved throughout the beta period. The revised scheduling rules make it so Sapphire XC can reach 98% efficiency with its 8 lasers, which is a big contributor to its ability to achieve a five-times improvement in performance.”

The print preparation software is able to generate and leverage meshes of models containing ‘up to hundreds of millions of triangles’. Velo3D says this capability is made possible by offloading the computation of larger files to Amazon Web Services. The customer sends a CAD file and receives back a compacted file that can be used on any printer to build the part.

The software also includes revised scheduling rules to achieve the claimed 98% efficiency of the Sapphire XC’s lasers. while the overall benefits of Flow 3.0 will apply to all three models in the Sapphire product family now offered.

“By providing an end-to-end solution we are able to let engineers focus on building the mission-critical parts they need,” said Velo3D director of engineering Daniel Russel. “The 3.0 release brings support for the sorts of large models that can be printed on Sapphire XC, warnings and guidance to customers during build preparation, along with tools for managing build preparation on clusters, Amazon Web Services, and many other improvements. The initial feedback we’ve heard from our customers has been very positive.”