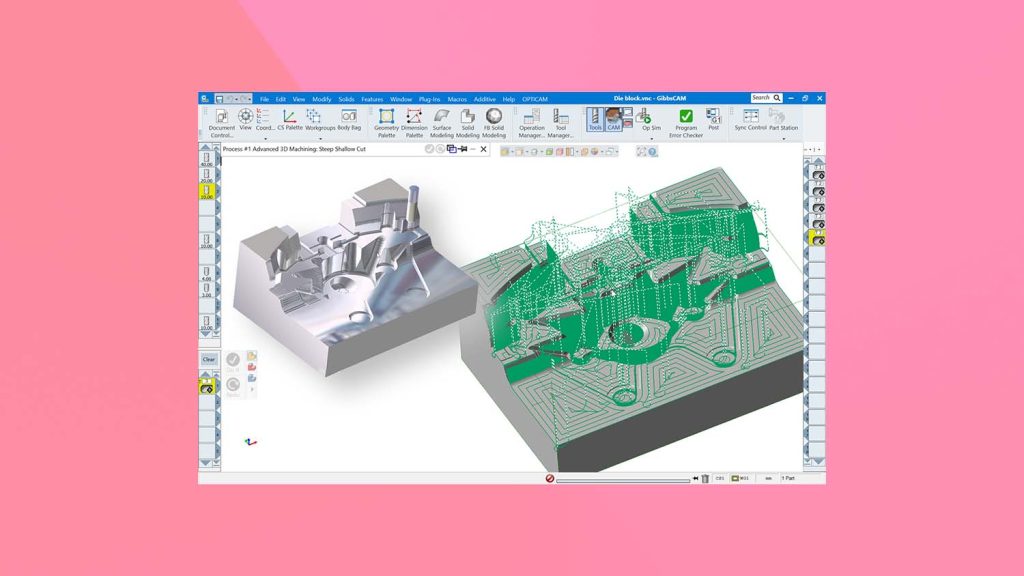

In its latest version, GibbsCAM 2026 has unveiled its latest development – a new Advanced 3D Machining engine – capable of delivering faster calculation times, more efficient toolpaths and improved surface quality.

Completely re-engineered from its predecessors, the Advanced 3D Machining Engine offers rapid toolpath generation speed, allowing faster programming cycles and fewer iterations. It produces smoother, more predictable toolpaths, leading to superior surface finishes and the reduced need for secondary finishing.

Despite the major architectural shift, GibbsCAM have maintained the familiar user interface to allow current users to benefit immediately without retraining.

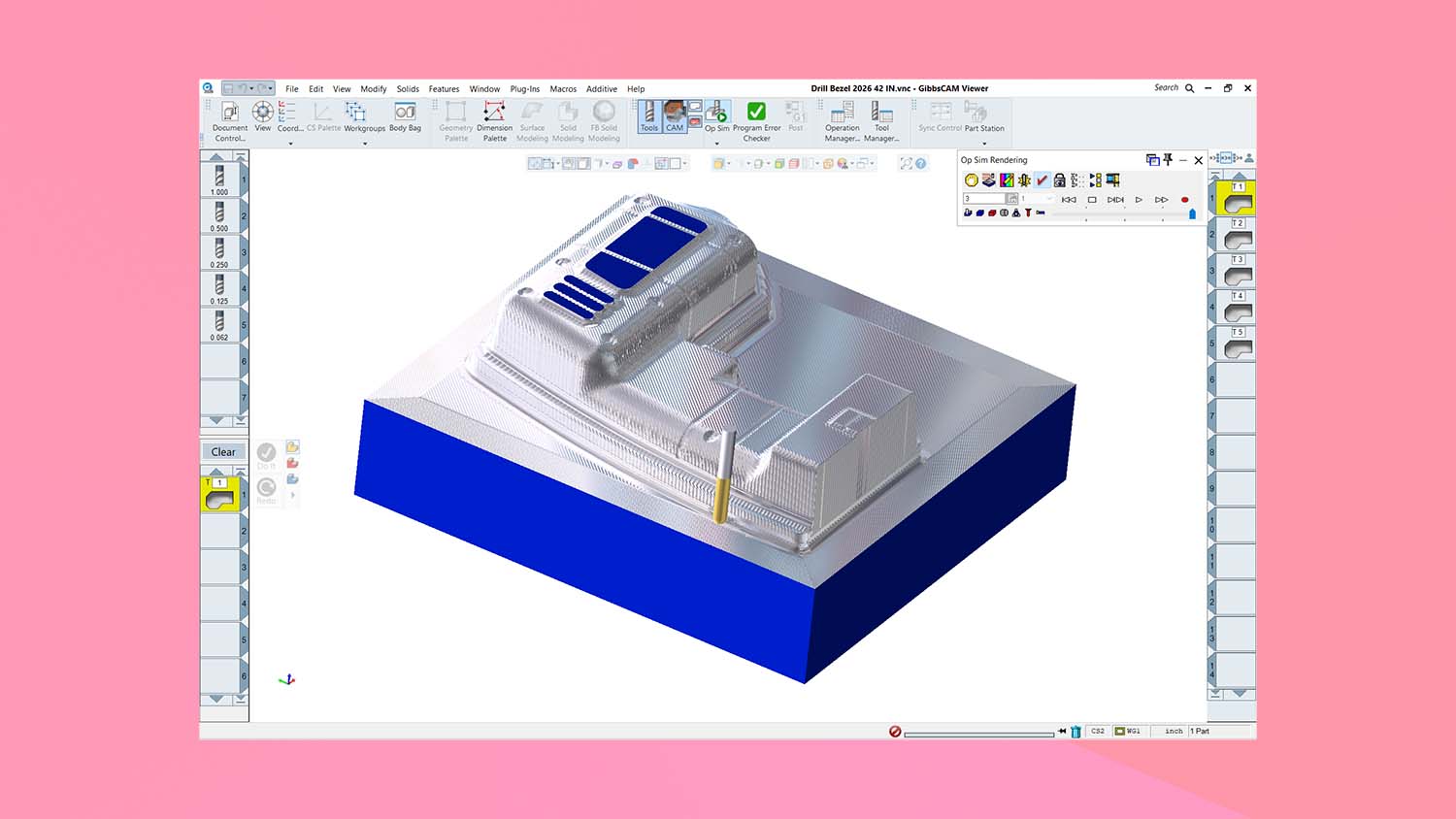

GibbsCAM 2026 does however see a fresher UI in GibbsCAM Viewer to enable more intuitive company-wide data access. CAM data will be available for review, inspection and to aid communication across a company without the risk of altering toolpaths or NC code.

Operators, managers, and quality teams can visualise parts, verify geometry, analyse toolpaths and generate reports using the same familiar interface. This tool should streamline communication and reduce errors while keeping programming data secure. Machinists in particular will be able to run parts with greater confidence and knowledge of what to expect.

There are also enhancements to Variable-B Turning in the 2026 release, allowing programmers to define tool angles directly along the cut path using control points, with smooth interpolation for precise control over complex operations. This can make Variable-B Turning more flexible and easier to use, reducing setup effort while improving accuracy.

For Multi-Sided Turning tools such as Sandvik Coromant’s CoroTurn Prime inserts, toolpath generation is now smarter and more efficient. The system calculates material engagement intelligently, maximizing insert geometry while maintaining safety. The result is improved material removal, consistent operation, and greater efficiency in advanced turning tasks.

Other upgrades come with smarter tool management via the new Tool Usage Reporter, offering operation-based tracking of all tools, while there’s an expansion of multi-axis and 5-axis capabilities with new advanced tilting strategies.

Multiblade machining also sees significant improvements with a new Edge Finishing strategy offering high-quality surface results while protecting delicate leading edges, and expanded tool support now includes flat end mills, bullnose mills and taper tools. Users can customise feed rates for links, lead-ins, lead-outs, and edge extensions, reducing non-cutting time and optimising cycle efficiency.

GibbsCAM president Thorsten Strauß, said that GibbsCAM 2026 is important step forward. “I am proud of the dedication and expertise our team has demonstrated in bringing this release to life, and I am excited about the opportunities it creates for manufacturers. The new Advanced 3D Machining engine, combined with our continued focus on usability and intelligent automation, represents not only a major achievement today but also a strong foundation for the future of CAM. We are committed to supporting our customers on their journey to more efficient, reliable, and innovative manufacturing.”

Part of Sandvik Manufacturing Solutions, GibbsCAM integrates with all major CAD systems and supports 2 to 5-axis milling, turning, Swiss machining, multi-task machining (MTM), and Wire EDM.

Also announced this week, GibbsCAM users will soon be able to benefit from CloudNC with its AI plug-in that generates toolpaths for 3 and 3+2 axis components, accelerating strategy creation, removing bottlenecks, and ensuring your programmers are even more efficient and productive.