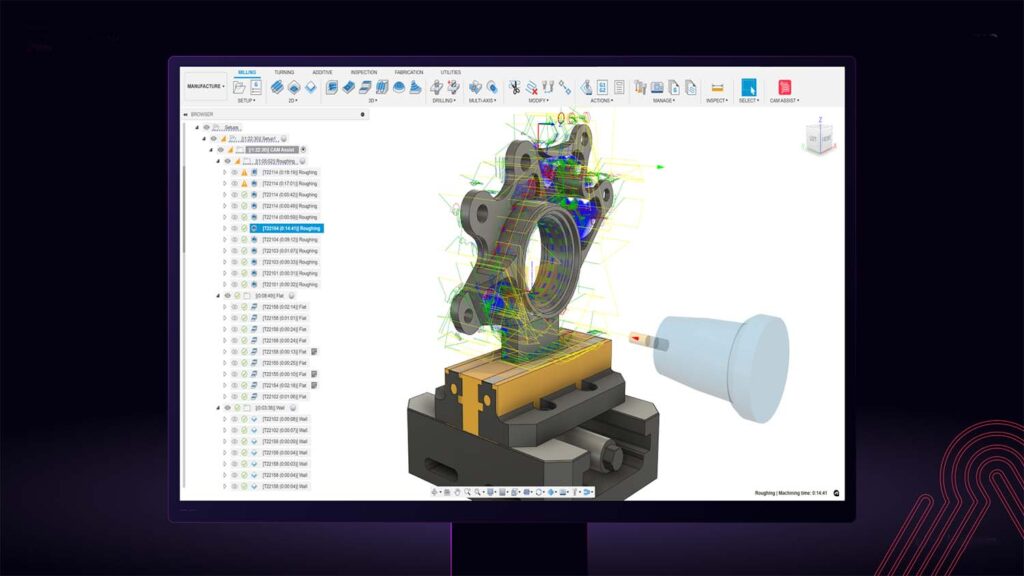

CAM Assist can now create machining strategies for 3+2 axis CNC machines – using its AI abilities to support a greater number of manufacturers with the potential efficiency gains.

With 3+2 axis support in place, CloudNC estimates that its software, available as a plug-in for Autodesk Fusion, can help around two-thirds of the CNC machining market.

The software uses computational optimisation and AI inference to rapidly determine a professional strategy and toolset needed to manufacture a part, along with the most appropriate cutting speeds and feeds from the user’s library. The process allows it to generate machining strategies in minutes or seconds, depending on complexity, which could take CNC machine programmers hours or even days to manually create.

As a result, CloudNC says it is capable of saving an average workshop over 300 hours of programming and estimating time a year.

CloudNC CTO Dr Andy Cheadle, said of the news: “This upgrade is not only a huge step forward in making CAM Assist even more useful for manufacturers around the world, but it is also an incredible technical achievement.

“From an R&D perspective, 3+2 axis support is exceptionally challenging, as the extra elements it involves introduce more potential ways of making every feature of every component, by several orders of magnitude.”

CloudNC is currently undergoing beta testing in other CAD software packages, noting that it expects to launch its solutions for those later in 2024.

CloudNC founder Theo Saville, said: “CAM Assist is the biggest paradigm shift for the precision manufacturing sector in decades.

“By making CAM programmers faster, CAM Assist enables manufacturers to increase machine uptime, slash lead times, improve process stability, and upskill staff to become expert machinists more quickly.”

The UK start-up is targeting autonomous manufacturing, with investment from Autodesk, Lockheed Martin and Atomico.