When it comes to producing a new product we have never been more spoiled for choice with all the technology available to assist in the process.

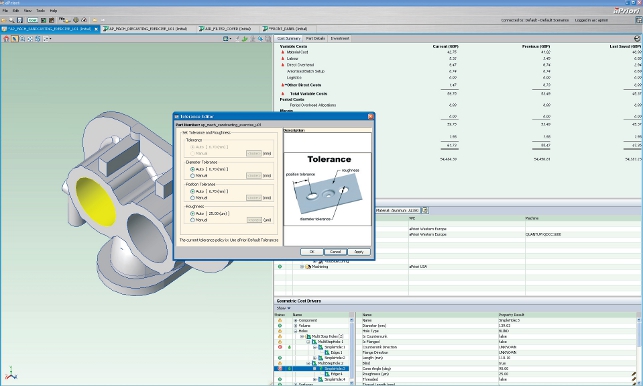

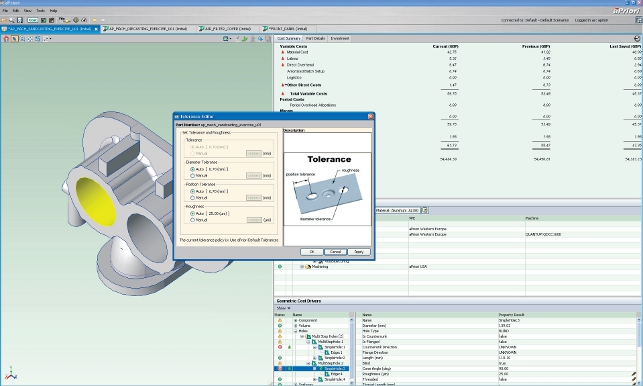

Default tolerances for each feature can be over-ridden by user specified values

From the ideation tools and pure search in terms of the Internet, through the development, simulation and refinement of detailed designs and into the world of manufacturing and production, these are indeed, interesting times. But amongst this rich tapestry of mind boggling comprehensive tools, there’s perhaps one key factor often missing. That factor is cost.

This is where aPriori comes into the mix. Developed by a team based in Concord, Massachusetts, aPriori is billed as a Product Cost Management solution. However, it has only recently started to actively market the software outside the North American market.

This is set to change since the team at Applied Group now have the ability to sell the product and associated services to the UK and many other countries in EMEA. So, how does it work and what are the benefits?

Basic workflow

A CAD geometry of a part is imported into the system. Its material, manufacture process, location of manufacture and the part volumes are then defined over a certain period of time.

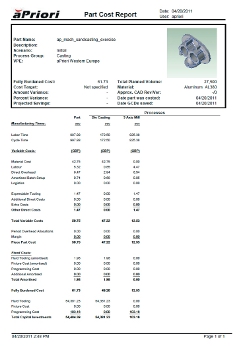

A break down of the costs likely to be incurred is given. This is based on industry average cost factories at one of a number of global locations down to the piece part level. To get an understanding of how the system works, we’re going to quickly run through the workflow.

The first step is to import your CAD geometry. aPriori can read 3D solid CAD models from any major CAD system on the market today, including Pro/Engineer, Catia V5, NX and Solid Edge, SolidWorks, Inventor as well as STEP and Parasolid data from any system that can output these formats.

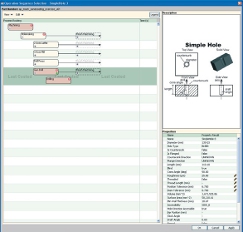

Once imported, aPriori then extracts what are known as Geometric Cost Drivers (GCDs). This involves inspecting the parts to find features and attributes that drive the cost. aPriori is not dependant on the way the CAD system has created the features: it has the ability to interpret the raw geometry. These range from the basics such as size (volume, mass, thickness) and include the complexity of features.

The system can also take into account surface finish and tolerances. It’s worth noting that these have to be defined for key features within aPriori, there’s no stripping out of PMI or GD&T from the CAD data as yet.

The intended manufacturing process is then selected. Again, a standard set of process groups is supplied including bar and tube, casting, forging, plastic moulding, machining and sheet metal. Unlike other basic costing applications, aPriori has a much deeper understanding of these processes.

For example, with a sheet metal component, the system has the ability to cost for a number of ‘sheet metal’ processes, from basic laser/water cutting through to press brake based manufacture and into the realms of progressive die. It can also factor in basic nesting on standard sized sheets, scrap and reuse. Essentially, the system will select the cheapest method that can manufacture that particular part.

With the part geometry, material and manufacturing process selected, the location for intended manufacture is then defined. aPriori supports cost calculations for manufacturing in seven geographic regions, including Western and Eastern Europe, US, Mexico, Brazil, India and China.

All these inputs are then evaluated by what’s referred to as a Virtual Production Environment (VPE). A VPE can be thought of as a digital factory that holds comprehensive information about the production of different types of products.

At the base level, this starts with material, which is selected from a wide range of options from the supplied database. VPEs also include an extensive range of machines used for operations such as sheet-metal fabrication, plastic moulding, casting, forging, machining as well as finishing treatments.

Lastly, VPEs include cost accounting data for things like labour and overhead costs. The whole process, using the default data sets, takes just a few minutes. A baseline cost for that part is then presented. Now it’s time to experiment.

Experimentation possibilities

This is where the potential for this system becomes abundantly clear. A complete breakdown of the costs involved in the production of a single part is provided. Any of the values can be switched around, swapped out and volumes played with.

One scenario that intrigued me was the ability to switch manufacturing location. It’s obvious that manufacturing in lower cost economies means cheaper parts, but it’s not often that you can accurately

factor in the cost of shipping.

With aPriori, you can. Also, with many organisations bringing manufacturing either closer to home or even in-house, it’s entirely possible to sanity check those decisions based on realistic data, rather than guess work. aPriori even supports combinations of manufacturing locations.

For example, a part may be cast in a foundry in Eastern Europe, with painting and final assembly taking place in the UK. aPriori can combine the cost and logistics associated with this type of real world scenario.

Rolling up assemblies

So far, we’ve only discussed piece parts but aPriori can also work with assemblies. Individual piece parts in an assembly can be costed as described earlier. It can then factor in welding and mechanical assembly.

Specific costs can also be included, such as the time taken to pick and pack components. Bought in items, which haven’t been modelled such as washers and bolts, can be added as a simple item with a bottom line cost. These are then rolled in to give an accurate representation of the total assembly costs. You can also build assemblies within aPriori. Additionally, an assembly can be ‘built’. This means that a fully defined 3D assembly is not needed to start the costing process.

Cost driven design change

Now, for me, this area has huge potential. As well as providing the cost of a near finished or signed off part file, the system can also link to your CAD system and give

a running cost while the part is actually being designed or redesigned.

Again, consider the development of a sheet metal part. As they grow in complexity, there’s an inextricable link to cost. As more geometry details is added to the design, the system will give feedback about not only the subsequent impact on cost, but also provide advice on the most suitable manufacturing process.

By rolling up all of the costs involved, you can immediately see the impact on costs and the effect it has on design choices.

Other points of interest

aPriori also has the ability to cost a large volume of parts in batch mode. This capability will be particularly interesting for folks in strategic sourcing. Imagine batch processing 500 or even 1,000 outsourced parts and comparing the price of what aPriori calculates as the “should cost” against what you are currently paying your suppliers.

This type of analysis allows the user to quickly identify those parts where suppliers may have been significatntly been overpaid. In summary, aPriori provides a tool and methodology for finding the “needle in a haystack” with minimal time and effort.

aPriori baseline factories that ship with the standard product have numerous levels of customisation available. The first example is that the user can quickly update prices of raw materials. Both the specific materials (material composition and stock size) a customer uses along with the price paid for those materials.

Information can be entered by reading a spreadsheet, which significantly accelerates this process. The more adventurous user can update the specific machines available for production to reflect their actual circumstances.

Parameters of a machine can be changed such as feeds, speeds, tooling options and assigned overhead cost. A new machine, incorporating things like capacity and overheads, can also be added. The third level of customisation – usually done by Applied or aPriori themselves, allows new processes to be incorporated.

These can include special decorative finishing or VPEs that represent a particular supplier’s capabilities and cost structure.

Conclusion

From the perspective of the designer/engineer, development of a part is often a question of evaluating the critical influencing factors and a process of making assumptions and decisions based on those factors.

Performance and function are key, but today, more than ever, cost is also paramount. With aPriori, the tools ensure that decisions are both functionally and economically sound. The ability to experiment with location, manufacturing process, volumes, materials and almost any other factor means you can truly optimise your design work.

It also ensures that whilst the customer is getting the product they want, you are not overburdening your organisation with additional, unnecessary costs.

From the management perspective, a system like aPriori has huge potential. If concerened about the cost of large volume parts, it can easily be found out if suppliers are out of whack with current costs. If potentially looking at redevelopment of common components, the system can show where it might be cheaper to manufacture those components.

And this is just taking the system defaults and running with them. aPriori has been built on an open platform that allows custom attributes to be integrated into the system. Whether that’s to match a particular industry, manufacturing processes or part types. It might even be to reverse engineer a stack of quotes from a supplier to gain some insight into costs far in advance of the RFQ process.

At the moment, aPriori is priced on an annual license fee, with additional set-up (if required) to develop custom VPEs to match specific production processes and supply chain. To give an indication of costs, we’re looking at around the £30,000 mark for a smaller organisation with five or so users and upwards from there as you add more customisation and users.

As a result, its sweet spot is for manufacturers looking at reducing part costs across high volumes of components. That said, there is potential for smaller organisations to find a use, particularly for more cost conscious ones or those looking to make your production processes more efficient.

Applied also offer use of the system on a bureau, per part or per project basis. So, if you have key concerns, you can deal with these on a pay as you go basis at a fraction of that cost.

www.aPriori.com

www.appliedgroup.com