By keeping the processing station separate from the 3D printing station, production with HP Multi Jet

Fusion can operate continuously, as the print station is not tied up waiting for parts to cool down

This May, HP finally pulled back the curtain on its long awaited Multi Jet Fusion 3D printing technology, which will eventually be capable of producing functional production parts from multiple materials in multiple colours.

Prototyping is an obvious key application, and HP plans to aggressively target this sector from the off with the promise of low cost, high speed production of parts. Longer term, however, it has much bigger aspirations. “The [3D printing] market has grown a lot but it’s still in the order of a 4 to 5 billion dollar market,” says HP’s Scott Schiller, VP of market development at HP 3D printing. “And there’s a $14 trillion overall manufacturing market so the question is ‘do you want to sit here in this little pool or do you want to take some really proactive steps to start advancing the state of the art?”

For 3D printing to really take off in manufacturing, machines not only need to produce accurate, functional parts, optimised for strength and surface finish, but quality needs to be predictable and consistent; the whole process streamlined and, eventually, automated.

HP is addressing this in two ways – first, through its closed loop thermal control system, which helps provide full control over the mechanical properties of parts, and second, by keeping its processing station separate from its printing station, which enables production to operate continuously, as the print station is not tied up waiting for parts to cool down.

While additive manufacturing is usually associated with very short run or custom manufacturing, HP believes that Multi Jet Fusion can actually be relevant to larger scale production. Here, one of its key examples is a 1.5-inch diameter gear.

2,500 of these functional parts can be produced every 6 to 8 hours in a single build on one of its 3D printers, explains Alex Monino, WW marketing & sales strategy director, HP 3D Printers. This in itself is impressive, but the assertion that it would be cheaper to print 55,000 or less of these parts than it would to manufacture them by traditional means gives a whole different perspective on the technology. With larger parts, he admits, this number would be in the 1,000s.

However, it’s not just about direct cost comparisons. With injection moulding, all 55,000 gears would have to be manufactured at the same time, in the same location, explains Monino. With 3D printing you have flexibility in both numbers and where the parts are manufactured. “You can decide that maybe you don’t want to print them all in China, so all the inventory or logistic savings you will have because of that [by manufacturing smaller batches, locally], they’re not counted in the 55,000. If you count that, then you would move that [breakeven point] even further,” he says.

Monino adds that HP will provide tools to help customers and channel make decisions on the applicability of Multi Jet Fusion to different manufacturing jobs, “They’ll be able to basically – for any given part – consult them and say, what will be the breakeven point versus another given technology.”

Gears – all manufactured on a HP Multi Jet Fusion 3D printer

Even when firms are committed to tooling, HP says that additive manufacturing can be used to bridge production bottlenecks and help bring those first products to market faster. “You get a tool because you’re going to make a million of something,” explains J Scott Schiller, VP market development at HP 3D Printing, “but you have to wait 16 weeks for the tool to be done. [With 3D printing] you can do your first 1,000 products [straight off].”

This ability to manufacture products quickly also makes 3D printing attractive to startups. It not only offers a way to create their first physical products without big upfront tooling costs, but can also help them innovate in their product development process.

“You’ve got engineers doing their capstone projects,” explains Schiller, referencing a University of Louisville (UofL) project with FirstBuild that gives students access to state-of-the-art manufacturing equipment. “They’re supported by Indiegogo where you have crowd funding and crowd sourcing of ideas and approval and interest, identifying opportunities that would never otherwise be found.

“There’s this area between making one bespoke thing because you’re a bit of an inventor and getting to mass scale production. And now I think people are starting to recognise the sort of recipe of what’s necessary in order to fill that gap. I think there’s going to be an explosion of lots of new ideas.

Here, Schiller draws many parallels with the software industry, which thrives on testing in the community, “You can just roll these ideas and get very fast feedback, and so forth. Now I think that’s starting to move into the world of tangible goods.”

HP believes additive manufacturing can also help reduce costs in assembly lines – by reducing the time taken (and skills needed) for assembling parts and by simplifying inventory management. To illustrate this point, Monino references a multi-part plastic assembly which HP has redesigned for a single build on its 3D printer. “[With the original product] there was an assembling process of twelve parts with screws,” he says. “Now it’s one part, and it’s printed. So it changes your concept of parts.”

Scalability

With an effective build volume of 406 x 305 x 406 mm, the current generation of HP Multi Jet Fusion 3D printers are limited in terms of the size of parts they can produce and the number that can fit inside a single build. The question on everyone’s lips is how scalable is this technology?

In short, the answer is very. Schiller explains that HP already has massive 2.8m wide inkjet web presses that run at 200 metres per minute and are capable of printing images with multiple chemistries. “That potentiality we can now take into this world [of 3D printing], but what we need to identify is what are the use cases,” he says.

“First we have to get to manufacturing as a capability,” he explains. “Fundamentally, can you guarantee the quality? Do you have the right level of performance? Do you have the economics to really justify higher-scale production? When we’re at that point I think we’ll be quite ready to scale as big as we can imagine. We don’t know where the limits are.”

Equally, the technology could be made available to smaller firms, but this seems less likely in the short term. “The technology scales up, and it scales down,” says Schiller, “but you really have to get into who are those people, what are they trying to accomplish? And make sure that you’re really serving their requirements. And [there’s] lots of work to be done to really sort all that out.”

Materials

With Multi Jet Fusion, HP is placing a huge emphasis on materials. In the future, parts will be able to be made with many different physical properties, which can vary throughout the body, down to a voxel (3D pixel) level.

There will be new applications, explains Alex Monino. “Whether it’s functional colour, whether it’s embedded circuitry, whether it’s embedded information, whether it’s parts that are both rigid and flexible, parts that are rough and smooth, we have a unique advantage there that we want to exploit.”

Materials take on their different physical properties according to three different components: the powder, the fusing agents and the process.

“The way you fuse one material is not the same way you fuse another one, even if it’s the same temperature,” explains Monino, adding that physical properties can be changed by different fusing cycles, even if the chemistry is the same.

Conversely, with different chemistries, fusing agents can also dictate the properties of parts in different ways, as Schiller explains, “The most basic is a chemistry that differentially absorbs energy. As a result of that it defines where things melt. There can be other agents that can create reactive outcomes. There can be other agents that just apply properties,” adding that HP currently has the capability to do that at 23 microns, but in the future it will be twice that resolution.

One of the most interesting materials currently under development is one that can conduct electricity. This will allow conductors, passive circuits, integrated electronic circuits and other features to be embedded directly within a part.

This could have huge implications for product development – in particular with the Internet of Things (IoT) – as manufacturers will be able to build ‘intelligence’ into parts or measure performance in real time.

HP likes to demonstrate this capability with a chain link that has strain measurement built-in, courtesy of conductive traces printed as an array of strain gauges. As weights are applied, the deformation is measured in real time and, using a Bluetooth-enabled controller, data can be sent to a tablet.

For critical applications, the ability to monitor parts remotely like this could alert engineers when components need to be replaced, or even to help avoid catastrophic failures.

“If something [a replacement part] has a lead time, you order it at the right time. It actually comes at the right time and you’re not down for three months because you didn’t know what was happening,” says Schiller. “I think there’s enormous potential there.”

HP’s Multi Jet Fusion technology also presents a much simpler way to monitor parts over time. A gear, for example, could be manufactured with wafer thin sub-surface layers that expose colours with wear and tear. This approach could also be useful for moulds to see when they are ready to be replaced.

To fully realise the benefits of changing the physical properties within a single build, down to a granular level, designers will need to change the way they think. Monino pulls out his smart phone which has a protective rubber bumper. “This is a multi-material product. This is flexible, this is rigid,” he says. “I’m not saying we can print this. But we need to think beyond the part, because there will be things that today are done with two parts, that then you’ll be able to do with just one.

“Toothbrushes are a perfect example. You want some parts rigid, you want other parts more flexible, or some grips embedded.”

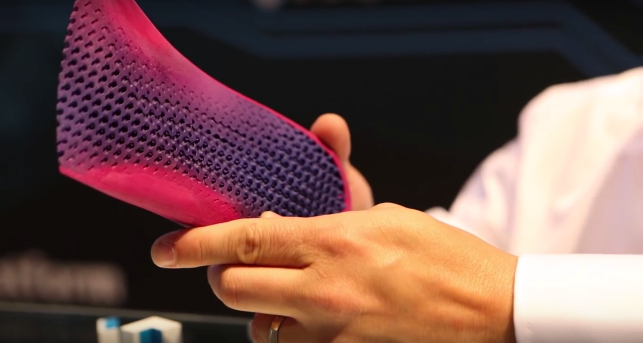

Flexible sample parts

Open, not closed

HP is developing its own materials but, importantly, is also working with partners including Evonik, BASF, Arkema, and Lehmann & Voss & Co to help create an open market. The idea behind this is to not only help drive innovation but to bring down costs.

Siemens is a huge advocate of additive manufacturing and already uses several different technologies to make production parts. These range from optimised replacement burner tips for metal turbine blades to spare parts on demand.

Ulli Klenk, VP for product management and sales, additive manufacturing and digital factory at Siemens, is particularly receptive to HP’s open approach, “[At Siemens] we do not like being bound to one supplier and we love this idea of open material development and material suppliers for the machines, and open as in general.”

Quality control is essential and HP will certify all third-party materials, as Monino explains, “We need to ensure [a number of] things. One is safety, first – these are high temperature materials. Secondly, that the parts you produce have the quality that you [the manufacturer] claims they have. So if you claim it has these kinds of properties, we need to certify that with all printing processes.”

Design software

HP acknowledges that design software also needs to adapt to support this new way of manufacturing, specifically to design single parts with granular control over material properties.

“The thing that I think most people don’t fully internalise is when you take the idea of Multi Jet Fusion, the idea that you are jetting chemistry that can digitally define where things fuse, but where things don’t fuse, and then in time where things have colours, where they don’t, where they have different attributes… It’s useless unless you have a design tool that takes advantage of it,” says Schiller.

“And what we recognised very early is we could have this most amazing machine that would be stuck in a glass case because there would be no design tool.

“Then once you have the design tool you have to have the education, so we needed to work, and work hard to get these roadmaps aligned, and really this is job zero to get things moving towards the world of the potential.

Here, Schjiller is referring in part to HP’s close association with Siemens PLM Software, a partnership that was announced earlier this year. Klink explains its importance, “When we talk to end customers the first thing they want to come to is how can we really use, or how can we utilise the design potential.”

Siemens NX will play a key role in this enabling users to design features that are specific to HP Multi- Jet fusion 3D Print technology, down to a voxel level. Importantly, these can then be simulated in NX CAE and the optimal manufacturing strategy defined in NX CAM.

All three can be done in isolation, but the biggest benefits come when the design to manufacture workflow is optimised within a single environment, explains Klenk. “You can do cherry picking, you can do your CAD, you can do your CAE and you can do your CAM. If you get that data on one basis and have it aligned…enjoy. It all has to be in one database, so when you turn one variable, it will link to the other systems. We think this is the optimal way to go.”

Next generation HP Multi Jet Fusion 3D printers will be able to print in colour

Optimised production

It’s one thing being able to make production quality parts with Additive Manufacturing. The real challenge, however, is building a highly efficient production environment around it.

Klenk believes that, in ten years, Additive Manufacturing will be a commodity – just another production method, like injection moulding, or milling. However, he acknowledges that there are still some obstacles to overcome before it can be brought into a true production environment.

Delivering predictable output is absolutely critical and he believes HP is taking big strides in this area, by being the first 3D print manufacturer to deliver closed loop control.

Klenk explains that current 3D printers [SLS, SLM, and powder bed applications] are more or less laboratory machines, “The material is brought to the machine by hand. The material is put on the machine by hand. The machine is started by hand,” he says. “In the worst case the data is actually also brought to the machine via a USB stick, then the machine is started by hand.

“It takes up to 72 hours to produce. Then it takes 48 hours on the machine for the part to cool down, so the machine is blocked. Then the part is taken off the machine by hand.

This process needs to be automated. “From Siemens’ point of view, the benchmark basically is a production line,” he explains, citing the example of the manufacturing process of a headache pill. “From the primary medical production through the production of the pill itself, through the packaging, until it sees the pharmacist, probably nobody touches the pill. But the full production flow is automated.

“The entire process is traceable, and the production facilities are able to hand out a certificate and prove the quality of the part.

“So if we want to take Additive Manufacturing into automotive, aerospace, healthcare, and the energy sector… it’s absolutely essential to be able to put certificates to the parts and to be able to produce on this high process quality level. And we see that HP has the potential and has a machine that will enable this.”

Klenk is particularly impressed with the open approach that HP is taking, referencing its machines’ closed loop control of temperature, which can be monitored throughout the build process. “The first step is to read the data, and the second step is to influence it real time,” he says, adding that if issues are found, corrections could then be made or production halted.

“The standard today [with other technologies] is a protocol that says ‘the building temperature was OK’. But… how OK was it? And how do we develop through the building process? That’s not protocol.

“I take the part off by hand, and after these 72 + 48 hours I take it to the CT, to a computer tomograph, and worse case I will discover that I just printed something for the rubbish bin.”

Conclusion

Few would deny that it’s taken HP a very long time to deliver on its Multi Jet Fusion 3D printing technology. But with a vision to bring 3D printing into the realms of commercial production, it is certainly aiming high. Short run production, spare parts on demand, complex parts, customisation and local manufacturing are all up for grabs.

While HP places an obvious emphasis on producing parts quicker and cheaper than the competition, it is the multi material capabilities of Multi Jet Fusion that are most exciting. The ability to produce single parts, with different mechanical properties throughout, could have a huge impact on how firms approach manufacturing. Assembly lines could not only be simplified by using fewer components but by embedding circuitry directly inside parts, firms may be encouraged to explore new IoT applications.

Of course, in order to make the most out of these exciting new technologies, firms will need adapt. “We’re going to have to go out there and educate the world,” says Stephen Nigro, president, 3D printing business, HP. “Now you think differently in terms of how you ultimately manufacture.”

HP Multi Jet Fusion

To learn more about HP Multi Jet Fusion, including the machines that are due for launch later this year, read our in-depth report.

HP’s vision to bring 3D printing into the realms of commercial production

Default