In the face of increasing digitalisation, the design and manufacture of electronics products and components has grown ever more complex.

At the same time, with additional layers of complexity also comes a far greater potential for thermal complications.

Nowhere is this more true than in the aviation sector. Aviation places a number of unique demands on electronic components and designs, all of which will need to be considered before an effective product can be manufactured.

For a start, the environments to which electronics are exposed during flight are significantly harsher than in most other industries.

At the same time, the need for bulletproof reliability is critical, with device failures and reliability issues having the potential to reap catastrophic results.

Given the level of risk involved, companies in the aviation industry work to extremely high standards in manufacturing and design.

Each part produced must undergo rigorous testing before being certified for use in an aircraft; those that show even mild fluctuations in reliability during physical testing will be sent back to the drawing board or simply destroyed.

From a thermal management perspective, this is particularly challenging. In order to prevent devices from overheating and ensure that they are working reliably, designers must think very carefully about the way that heat is produced and dispersed across their designs.

While this is a challenge for most electronics, aviation introduces a whole host of new considerations, including much wider fluctuations in temperature, pressure, humidity, vibrations and more.

Failure to account for these fluctuations in the design process has major implications for manufacturers down the line, with the vast majority of devices being dropped at the manufacturing and test phase because they cannot pass stringent physical reliability tests.

High standards fly even higher

While high standards have always been intrinsic to avionics manufacturing, two new trends in the industry are leading to even greater potential for thermal complications and future reliability concerns. These are:

1. The rise of digitalisation: The last decade has seen significant interest in digitalisation across the aviation industry. As a result, we are seeing a major expansion of avionics manufacturers embracing digital technology, enabling pilots to file a flight plan, pull up new approach charts and even use digital co-pilots, all via touchscreens, tablet computers and similar portable electronic devices.

With the move towards digitalisation comes even more complex electronics components that need to function reliably in the air. These components must be compact, lightweight, wireless-enabled and increasingly powerful – a combination which dramatically increases the potential for thermal complications and the need for careful thermal management during the design, testing and manufacturing processes. As a result, any digital instrumentation introduced must be as reliable as its almost bulletproof analogue counterparts.

2. Demand for high speed connectivity: The second key trend that we’re seeing in 2019 is growing demand for high-speed connectivity among business aviation operators. An evergrowing number of device manufacturers now supply high-speed aircraft modems, antennas and other electronics designed to deliver airborne connectivity. Many of these also add digital elements to onboard systems, in order to extend their worth and give operators the ability to digitally customise how their aircraft acquires, analyses and transmits flight data to and from ground-based servers.

Once again, this adoption of wireless technology comes with a whole host of additional electronics components and demands, all of which need to function reliably across temperature, altitude and pressure fluctuations.

CFD – solving through simulation

As the complexity of aviation technology increases, avionics designers and engineers cannot risk downgrading reliability for new functionality.

At the same time, we cannot go on producing designs that inevitably get scrapped as soon as it comes to the manufacturing and test process. Such an approach is both costly and wasteful and will only become more so as digitalisation increases.

In response, manufacturers and engineers need to move this testing process further forward within their product design lifecycles.

Instead of expecting the majority of products to fail at the manufacturing and test phase, they need to limit the potential for thermal complications and reliability issues before a product even goes to prototype. This is increasingly being achieved through advanced simulation and the use of computational fluid dynamics (CFD).

Using these tools, aviation products – whether a touchscreen flight planning system or a new onboard communications node – can be simulated virtually, creating an accurate depiction of heat flow and potential reliability issues.

As CFD tools have grown more advanced, designers can even automatically model physics, such as altitude corrections, heat and solar radiation and liquid cooling considerations. This is ideal for the extreme environmental conditions and unique cooling processes associated with avionics.

CFD – rethinking design at Ten Tech

As just one example, consider the aerospace company Ten Tech. It recently collaborated on the design of a new liquid-cooled airborne radar processing chassis.

This was a very high-powered, high ambient temperature design, which had no cooling mechanism other than a single liquid cooling loop. A little under 3kW had to be dissipated out to the (already hot) environment in order for the electronics to function reliably.

A team at Ten Tech started its work with the redesign of one of the cold plates, since the initial design would not have provided enough cooling. The cold plate design also had to account for pressure-drop requirements.

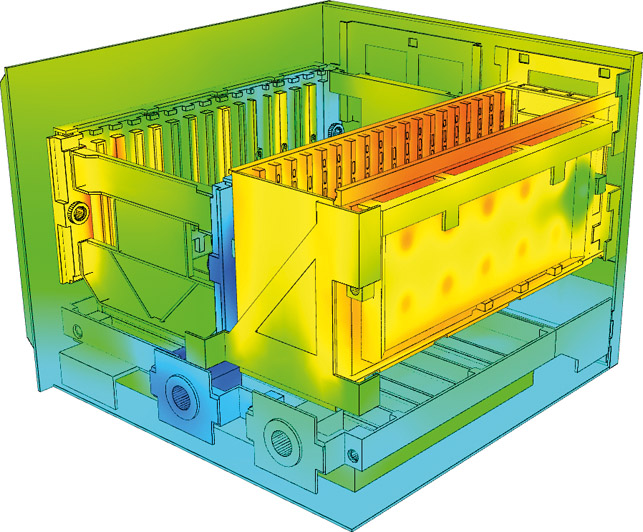

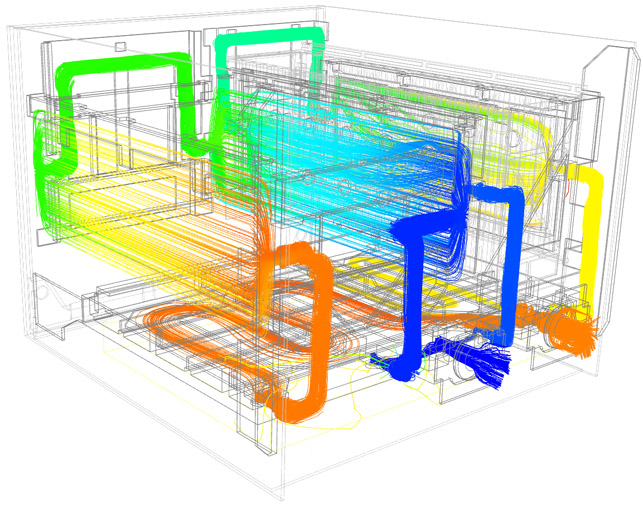

Working with 6SigmaET thermal simulation software, the company ran thermal CFD analysis to better understand the heat flow and to maximise cooling and minimise pressure drop.

Ten Tech was able to quickly create a multi-fluid model of the cold plate involving free convection and liquid cooling and optimised the cooling channels to obtain a good compromise between heat dissipation and pressure drop through the cold plate.

Once this stage was complete, the Ten Tech team moved on to understanding the liquid cooling of the entire system.

This larger chassis included over 25 high-power single-board computers (SBCs) and five cold plates of various complexities.

Using CFD simulation, they were able to ensure that the entire chassis was properly cooled, the liquid loop would function correctly and each of the single board computers would remain within its temperature requirements.

Rather than manufacturing multiple prototypes, or expecting a large number of product designs to fail at the test phase, thermal simulation allowed Ten Tech to move towards a ‘right-first-time’ approach to building reliable products. As such, across just this one project, the company was able to make an estimated cost saving of over $50,000 in test failures and programme delays.

As the aviation industry evolves and digitalisation becomes the ‘new normal’, those designing and manufacturing avionics will need to think more carefully about the way that heat is managed across their designs.

With the correct thermal considerations built in from day one, businesses can focus on right-first-time manufacturing, significantly reducing the number of products that fail the testing phase.

This will not only prove beneficial for businesses but will also free up manufacturers to streamline their processes and produce reliable products at a more cost-effective rate.