BioLite helps get customers cooking efficiently with biomass fuels in offgrid environments

For some people, going off-grid is an adventure, a welcome release from the everyday. It’s a chance to get back to nature and connect with the great outdoors.

For many others around the world, however, energy poverty amounts to a painful, day-to-day struggle. In fact, for this latter group, a reliance on unclean and unreliable energy sources leads to four million premature deaths annually, restricts time available for education and curtails social activities that so many of us with wired-in power take entirely for granted.

While this situation might seem a world away from a jolly camp-out with friends, Brooklyn, US-based BioLite believes that the needs of both groups can be tackled in parallel.

The company’s unique approach, which it calls ‘Parallel Innovation’, enables its team of designers and engineers to incubate core energy technologies and turn them into products that suit fans of outdoor pursuits and customers in emerging markets alike.

“We found that a lot of the core energy needs that you have when you’re off-grid are the same in both of those situations,” explains Ryan Gist, director of engineering at BioLite. “And in both situations, people need reliable products that are cost-effective and energy-efficient.”

The company started with its flagship product, a camp stove that efficiently burns readily available biomass (for example, wood) instead of fossil fuels, and converts some of that heat into electricity – a bonus when you’re off-grid and need to cook, illuminate your campsite and charge electronic devices such as smartphones.

“We waste a ton of heat when we’re cooking – it’s only about 30% of the heat that goes into heating your food. The rest is lost out into the world,” says Gist, a former rocket engineer with a knack for thermal combustion science.

“So just converting a small amount of that [wasted heat] into electricity provides useful charging for stuff like a cellphone or a headlamp.”

The heat from the fire powers a fan that cools the cold side of the power generator, so that it makes more electricity, but the air from the same fan can then be used to force more oxygen into the fire.

This improves the combustion performance of a biomass stove enormously, meaning faster cooking times and more electricity generated, while the increased heat means more particulate matter (smoke) is burned before leaving the stove, vastly reducing the fumes emitted.

BioLite’s ‘Parallel Innovation’ approach has enabled it to adapt its products to meet the needs of families in developing nations

BioLite – hot stuff

In 2008, BioLite’s founders took their initial working prototype of the camp stove to a conference where they quickly discovered that their technology could potentially have a far bigger impact on the world.

Half the planet lives in energy poverty, lacking safe and reliable ways to cook, charge and light their lives. Three billion people cook over smoky open fires in homes every day, with serious repercussions for health.

BioLite’s designers decided that while they had the technology to tackle the problem, the design brief for the camp stove had changed. For customers in emerging markets, cooking up to three meals a day on the stove, the product needed to be “very robust, durable and longlasting,” says Gist.

“They’re cooking much bigger meals for the whole family, but it’s the same idea: you’re converting some of that waste heat to electricity, and now people who live off-grid are better able to charge their cellphone, which is typically the first piece of modern electronics that they have, without having to walk to the next village and go pay someone at a kiosk,” he explains.

The design solution here was a bigger, more durable stove for use indoors, complete with cooking light, power generator and USB outputs. Its success allowed BioLite to expand its operation, nearly doubling in size and establishing an office in Nairobi, Kenya, which handles sales, marketing and after-sales service, including technicians who provide service calls.

From feedback collected from technicians and ‘last mile’ distributors, the team at BioLite soon realised that customers needed even more power, in particular to provide lighting that would extend their productivity beyond daylight hours.

The Solar Home 620 kit comes complete with power storage console, three lights and a solar panel for charging devices

“The heat-to-electricity conversion [of a stove] is very cost-effective when you’re talking about a small amount of electricity – a few watts up to five or 10 watts. But when you need 15 to 20 watts or more, then solar conversion is a much more cost-effective means of doing that,” explains Gist. This prompted BioLite’s move into new solar products.

Bio Lite – fantastic photovoltaic

Like the stoves that came before them, the new solar products were designed and engineered in-house. “We’re definitely a design and manufacturing house,” says Gist as we look around the office, a former warehouse that sits close to the water of the East River in Brooklyn’s Dumbo neighbourhood (the quirky name is shorthand for ‘Down Under Manhattan Bridge Overpass’).

“We’ve got a team on the product development side of about 10 engineers and industrial designers that do all the product design,” he adds.

The team operates using a 7-phase development cycle, beginning with the product team in Brooklyn defining the product opportunity from feedback from Nairobi, assessing the price sensitivities involved and customers’ actual needs in terms of power and lighting.

Everything from design to product testing happens at BioLite’s Brooklyn, NY-based headquarters

Once a product spec is reached, the development cycle continues into three phases of design and engineering, and a further three phases of design for manufacture, quality assurance and the supply chain.

“We use a lot of Rhino and Keyshot for industrial design, but SolidWorks is the core CAD platform,” says Gist, adding that, within the Dassault Systèmes software, they produce the bulk of the design and engineering models, work on product definition and pull out the data needed by contract manufacturers in Asia to work on the production tooling.

Increasingly, the development team has turned to inhouse 3D printing to assist with the development phases.

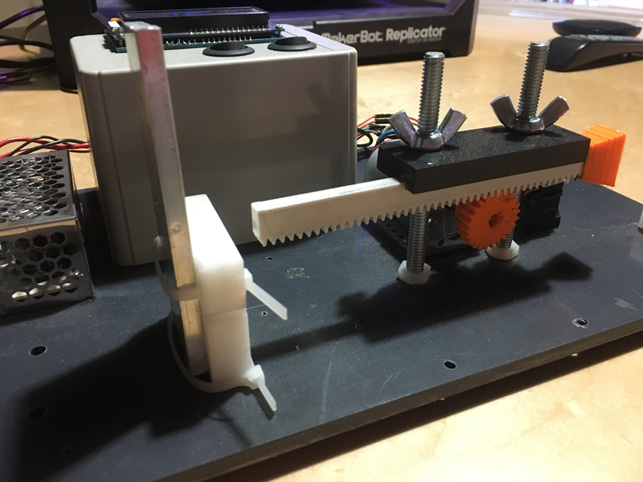

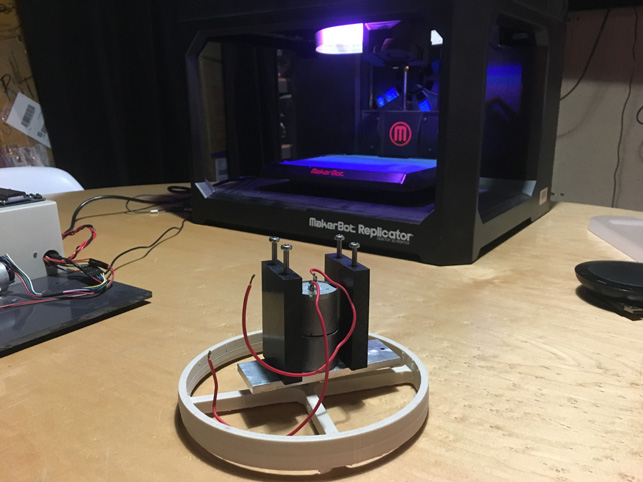

The growing workshop features two Makerbot Replicator 2 3D printers, with this pair of FDM machines proving to be valuable across all phases of the development cycle.

“The FDM printer isn’t the highest fidelity printer. We don’t use it for really tight-fitting components or assemblies, but it can help us to learn a lot about where the sticking points might be,” says Gist.

“What I’ve found, which has been really great, is what we ended up using it a lot for was not just the product itself, but for support equipment around the product development process.”

While 3D printing is often seen as an enabler for producing complex geometries – parts with undercuts that would be hard to mould or machine – it’s the ability to run without human interaction that benefits BioLite most.

“It’s just a lot more efficient for our engineers’ time to set up a run like this overnight while we’re at home sleeping and have it ready to go the next morning to start testing, instead of spending half a day in the workshop,” he says.

While a Formlabs Form 2 3D printer is used for more detailed work, like building a marketing prototype, or for assessing tight tolerances, the MakerBots are more versatile.

For a new BioLite product line of headlamps, a wheel with different surface textures was 3D-printed and added to a basic rotary motor for rub-testing of soft goods, while a simple rack and pinion machine was also created to perform repeated stretch-testing on the same material.

In-house testing like this saves a lot of time and money, and with a new in-house workshop area now set up, Gist hopes his team can fit the 3D printers alongside other important test equipment for electrostatic discharge testing, as well as the company’s aluminium photometric sphere for total light measurement testing.

For BioLite’s Solar Home 620 product, all of this equipment proved invaluable, both in terms of the core product’s rapid development and its parallel development as a component part for the outdoors market.

As a package for emerging markets, the design is a safe and clean energy source that’s simple for the user to install and get running straight away.

“In a box, there’s a solar panel that goes up on [the customer’s] roof; they get three hanging lights that look just like any modern hanging lights in a home and that come with wall switches that you switch on when you walk into a room, just like in a home that is fully electrified,” Gist explains.

“One of the lights has a motion sensor, which is often used outside as a security lamp, and the main battery storage box where all the energy is captured and stored also serves as an interface that lets you know on the power dashboard how much battery you have and how much solar energy you’re making.”

The wall-mounted storage box, meanwhile, also features its own light, a radio and an MP3 player, as well as a bunch of USB and other ports, so that customers can charge other electronic devices.

The team at BioLite uses two Makerbot 3D printers for many different purposes; in this case, for building product test rigs

The Solar Home 620 is not just a power storage unit, but also a way to charge devices and light homes

Bright futures

After its initial success that saw 70,000 units sold in 2018, BioLite’s solar power kit is expected to shift more than double that number in 2019, and plans are underway to scale up the system, as well as create more entry-level products.

Key to the design and evolution is the all-important feedback from sources across Africa, where BioLite is implementing a pay-as-you-go system of charging, a common model in emerging markets.

“It basically means that there’s an encryption protocol built into the product that will only unlock when you have the right access code,” says Gist.

“People will make a payment and get an access code, typically an SMS text to their phone. They punch in the code and [the system] unlocks for whatever the payment period is. If they don’t make the payment, then the system shuts down and it’s got a bunch of internal safety protocols to make sure you can’t tamper with it.”

At the end of the payment process, the customer becomes the full owner of the Solar Home kit, but they then have the opportunity to continue making regular payments in order to build a fund to invest in an expansion system.

The expansion system will allow for four times as much power to be generated and stored, and more lights and devices to be powered. In turn, this offers BioLite the opportunity to move into new product sectors, such as LED televisions or cooling floor fans that can be added to the network over time.

“We want to work towards refrigeration and ‘productive use’ appliances – things like hair-clippers if you want to run a barbershop, or a sewing machine,” says Gist.

“The cool thing about our approach is that you are building off the original system that you purchased, rather than buying a small system and using it for a while, and then having to ditch that and buy a much bigger system.

Kickstarter is used by the company to trial new products such as its new HeadLamp

The CampStove 2’s fan creates a smokeless fire to cook meals and boil water in minutes and turns heat into usable electricity

BioLite has an in-house product development team of 10 engineers and industrial designers

You can continue to grow.” Meanwhile, the solar systems still have appeal for customers in advanced economies: for those who vacation in off-grid cabins, for example, or for ‘digital nomads’ living and working out of vans, but with kit like computers and photographic equipment to charge.

The BioLite product range now numbers over 20 items. A series of Kickstarter launches has been important in getting these products to market and establishing the company’s brand.

“It’s been really great on the last couple of launches as a way to get the word out, because we found ourselves launching a lot of new products in new categories that we’ve never played in,” says Gist. “It also helps us gain some confidence that we’re entering the right markets,” he adds, explaining that a Kickstarter campaign has proved a good way to test the market and then work on forward strategy.

From positive reactions on Kickstarter, to positive benefits for families in the developing world, BioLite’s innovations are really earning their glowing reputation.

BioLite’s bright approach to design

Default