With the owner of a 2002 Maserati GT Coupe looking to upgrade to a more modern in-car entertainment system, Long Racing worked with Envision 3D Art and KVS’s Mesh2Surface to fulfill the customer’s wishes

Maserati: a symbol of excellence, royalty and elegance. But even with its timeless character, it’s not uncommon for the proud owner of a Maserati to want something new and original for their own vehicle, involving the sensitive application of twenty-first century designs and technologies.

At Magnolia, Texas-based Long Racing, the recent restoration of a 2002 Maserati GT Coupe interior involved an upgrade to the sound system, with the replacement of its radio with a large, modern touchscreen.

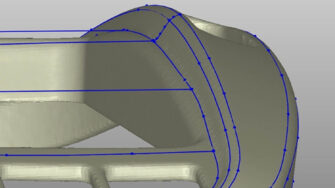

The big challenge here was that the original dashboard had complex and elegant contour surfaces that would be difficult to extract using traditional contact measurement tools. So instead, Long Racing contacted Envision 3D Printing, based in Spring, Texas, where the team collaborated with Mark Solly of Envision 3D Art for design solutions.

In-car upgrade

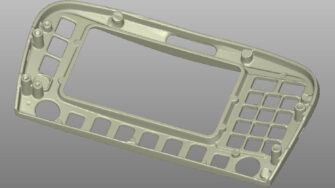

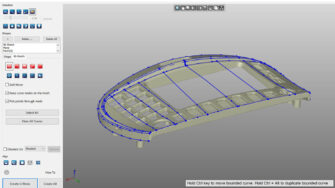

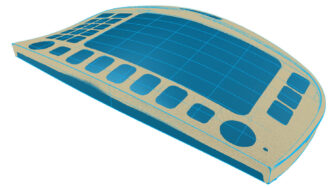

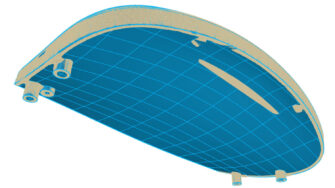

The task was to modify the design of the radio bezel to accommodate the latest technology in sound and communications. Solly suggested the best approach would be to 3D scan the original bezel, using a Einscan Pro 2X, then use Mesh2Surface by KVS for the reverse engineering tasks. This approach offers restoration shops the speed and flexibility to design custom interior automotive parts without additional inspection tools.

A further challenge was to recreate the bezel without the openings for the existing screen, knobs and push buttons, and without changing the solid design where the part would attach to the interior.

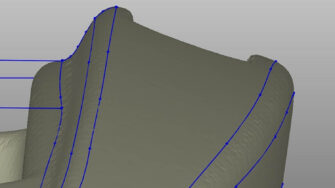

Solly knew that commonly used mesh editing software would only create flattened bridges if he deleted areas and used the fill hole tools. Therefore, he chose to remodel new surfaces by drawing 3D splines over the mesh using Mesh2Surface.

“I chose Mesh2Surface as it is one of the best solutions on the market for reverse engineering. It provides the user with simple and efficient tools to define their needs and saves an enormous amount of time. The style lines tool in particular provided the main backbone for creating a surface,” says Solly.

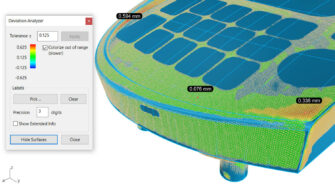

“And the built-in analyser helped me get the surfaces precisely within a couple of microns. With this software, creating the style lines was easy. With a couple of clicks, I could work directly on the mesh and see my deviations in real time,” he continues, explaining that for him, this was a faster, frustration-free and more accurate process.

Mesh2Surface – surface deviation analysis

The surface deviation analysis that comes with Mesh2Surface is designed to help users make necessary adjustments to surfaces and/or 3D splines by revealing how well they fit onto the scanned mesh file.

Once the 3D sketch was created, with straight lines and 3D splines that intelligently snap and bridge across to create traditional smooth surfaces, Solly finalised the 3D model. The object was shelled and the holding features were added.

The first 3D print was made at Envision 3D Printing, using the company’s Stratasys Fortus 380 with ABS materials. Finger holes were added to the prototype, so the customer could position the radio at the correct angle to the viewer.

Lastly, the final 3D print was vapour-smoothed, painted and integrated with the interior. The results speak for themselves: the restored Maserati can now boast a cutting-edge sound and communication system, one that easily rivals those seen in brand-new cars.