Lightweight or bust? The business case for lightweighting and AM can come with some bottlenecks, but as Alexander Pluke writes, the solution often lies in a better understanding of family dynamics

The challenge when it comes to cool things is that they can lead even the smartest among us to miss the most obvious facts. And let’s face it: lightweighting is cool.

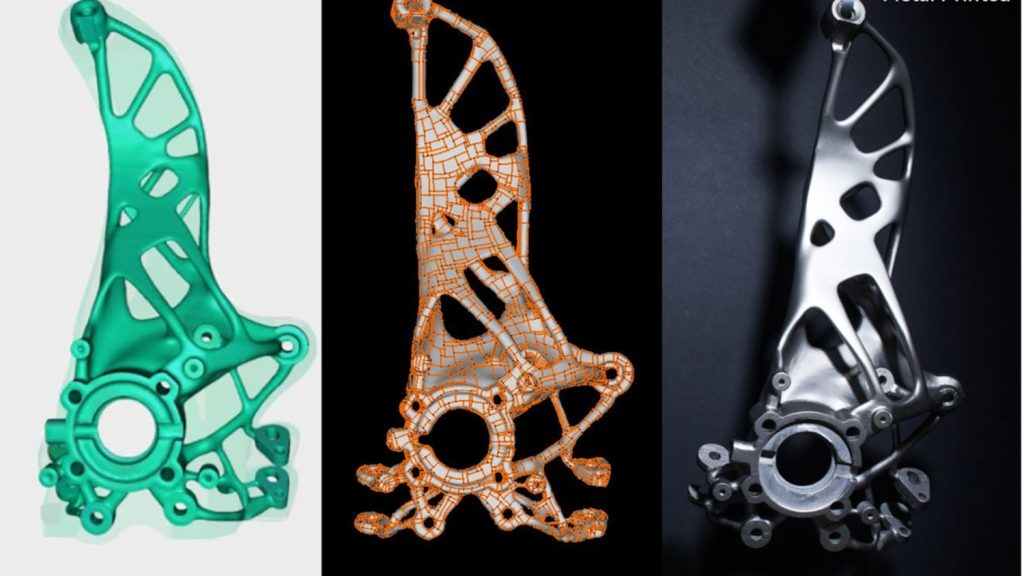

But amidst the beautiful design thinking, there are headaches, too, because design is only the start of the production story. This is especially true when paired with additive manufacturing (AM), where new materials, processes and geometries fly in the face of tradition, and can be difficult to stomach all at once.

There’s a lot to digest for design engineering’s wider family. First, in our analogy, we have the material science and simulation cousins, who must explain how these new materials and structures will perform. If behaviours can’t be predictably and repeatedly explained, then they can’t be used in real applications.

Then the elder siblings of production engineering must manufacture these fantastic parts. If operating workflows are too complex and costly, then scale production won’t be achieved.

Next, the aunts and uncles of quality engineering must ensure parts work as expected. If material and process variability combine with uncertain behaviours that are hard to measure, risks stack up and/or costs associated with avoiding part failure increase.

Finally, the executives — the parents in our analogy — must satisfy business needs. If lightweighted AM parts aren’t attractive when compared to other, more certain options, then applications won’t graduate to production at scale.

Family dynamics

Lightweighting is a business case that requires executive approval, and its success clearly relies on the whole family working well together.

While creative design engineer geniuses (the teenagers, if I may?) are focused on stunning lightweight creations, their elder siblings and aunties around the table are gawking at the implications. The parents, meanwhile, are questioning how much it will cost and when it will be ready.

All the while, everyone in the family is trying to be supportive, but recounting the struggles that arose the last time they indulged ‘Junior’s next project’.

The growing pains behind every lightweighting success story are a good sign. It shows that the engineering family is on a mission to adopt the designer’s newfangled approaches, but past methods of fixing production issues won’t work in this scenario.

The solution is found in getting the family together, tearing them away from their own siloed activities (or phone screens) to talk together around the table. Grumbles arise, thoughts are shared, goals are set, and in the end, each has a clearer view of the other’s perspective. This is especially important when adolescents come of age, and everyone needs to reset their expectations and grow.

In our analogy, this is easy to visualise, but in reality, it creates the logistical challenge of presenting a business case, in terms that the parents will understand, from a central pool of multidimensional information. And this becomes even more complex when different sides of the family speak different languages, and trade-offs in each choice affect different members in complex ways.

The frequency of required meetings, coupled with the issue of translation loss between groups in the workflow, may mean the family needs to spend all its time around the table — with no actual work being done.

Communication matters

This is one of the drivers for our work at Additive Flow: after a harrowing 80-hour week translating a ‘simple’ lightweight design to build prep with state-of-the art tools and back-and-forths between experts in the chain, I couldn’t bear repeating this torture each time we move from design to production.

If families are engines for sharing and improving learning between generations, the equivalent for engineers are the technologies and practices that teams evolve and deploy over time.

At Additive Flow, we’ve created a platform for consolidating and optimising across the different dimensions of data throughout the engineering family, while linking these with business case objectives for executive decision-making.

Through deploying best-of-breed standards such as volumetric 3MF, we connect across the ecosystem, reducing my 80-hour handover to minutes.

A unified optimisation interface allows production siblings and executive parents to trade off production speed and cost against design engineering’s optimality, while also keeping the aunties and uncles of quality engineering happy.

In the same way that parents share experiences outside the school gates, crosslifecycle family members working together implies a culture of more open innovation and data sharing between industry players as well.

More viable business cases equal more growth for everyone — and the multi-billion dollar AM student can graduate to the multitrillion dollar manufacturing world-of-work.

As well as the commercial gains, there are also meaningful opportunities for real-life families. Each kilogram saved per printed part is equivalent to the CO2 impact of two deciduous trees. This means our industry has the potential to deliver environmental benefits equalling thousands of acres of forest, year on year.

How’s that for an incentive to unlock the business case of lightweight AM for the next generation?

Get in touch:

Alexander Pluke is CEO and founder of Additive Flow, a software for the simultaneous optimisation of the entire AM workflow, which has worked with companies including Saint-Gobain, Royal Haskoning, Tata Steel and Zeiss to maximise their AM value. hello@additiveflow.com