Significant changes are happening in the manufacturing industry. The unprecedented pace of technology change, increasing consumer demands, and a growing skills gap are requiring manufacturers to reimagine the way they design and make.

Adopting design for manufacturing philosophies puts manufacturing processes, constraints, and limitations front and center, from the very beginning of the product development lifecycle – allowing businesses to grow, remain profitable, and stay competitive.

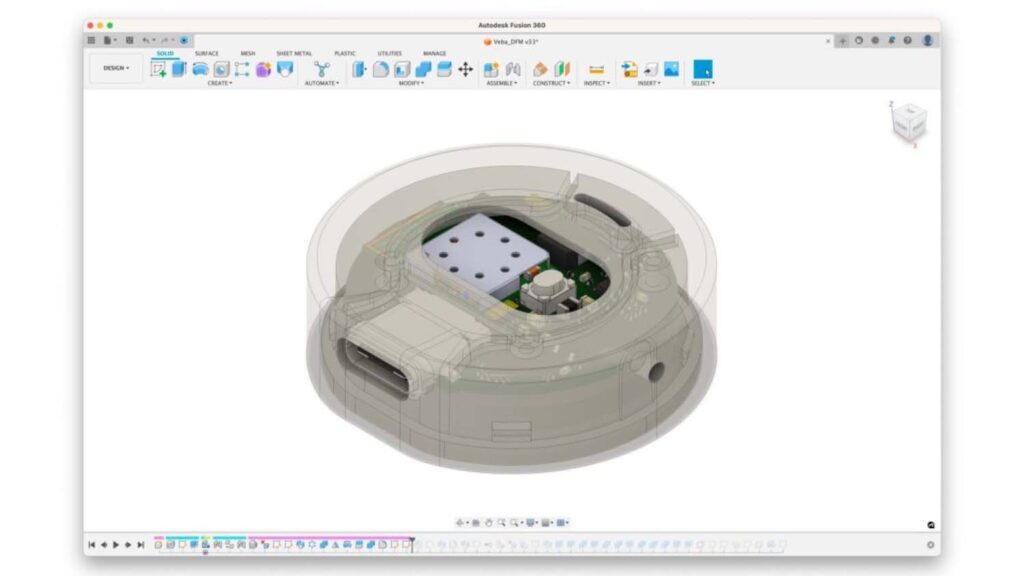

Manufacturers need solutions that make design for manufacturing easy. Autodesk Fusion seamlessly integrates CAD, CAM, CAE, PCB, streamlining processes across the entire product development and manufacturing lifecycle.

Autodesk Fusion excels beyond other solutions on the market with its unique and comprehensive set of features and capabilities. These key features in Autodesk Fusion make design for manufacturing easy:

Collaborative workflows

Autodesk Fusion offers a cloud-based platform that makes real-time collaboration among design and engineering teams easy. This collaboration ensures all stakeholders are on the same page, reduces communication gaps, and speeds up decision-making—crucial for successful DFM.

Product development firm Brash can solve potential conflicts between various teams with the collaborative tools in Fusion.

“With Fusion 360, we can each work on our own priorities in the same design space. It helps us make the most of our time. We don’t have to share files back and forth and make sure everything is transferred correctly. We don’t have to double-check units of measurement. It makes everything easier and minimizes the risk of errors that could cause delays. It saves us a ton of time.” – Tyler Berryman, Product Design Engineer, Brash

Cloud-based data management

Autodesk Fusion offers cloud-based data management, making it easier for teams to collaborate and access project data from various locations. This feature supports the collaborative nature of DFM, where effective communication and shared data are essential.

Efficient prototyping tools

Rapid prototyping is integral to the design process, and Fusion simplifies it by enabling swift prototyping through 3D printing or CNC machining. This allows designers to iterate and refine their designs rapidly.

Autodesk Fusion helped EDGE Sound Research develop the ResonX, a system that fuses acoustic sound with tactile sensations for the hearing impaired.

“The ability to iterate quickly was what really sold us on Fusion. No other software can do that for us.” – Vincent Zhang, Industrial Design Engineer, EDGE Sound Research

Flexible parametric modeling

Parametric design capabilities in Fusion enable the creation of flexible and adaptive models. This is crucial for accommodating changes that may arise during the manufacturing process or for producing products with custom, changeable dimensions.

Advanced simulation and generative design tools

Static stress simulation capabilities in Autodesk Fusion enable designers to assess the structural integrity and performance of their designs before manufacturing. This aids in identifying potential flaws and making necessary adjustments early in the process.

AI-powered generative design tools in Fusion help designers and engineers quickly analyze design alternatives by generating thousands of manufacturing-ready solutions for a defined problem.

Kawai Plastic Industry, based out of Japan, implemented the Autodesk Fusion Simulation Extension for injection molding simulations and reduced the number of trial injection runs by 25%

“The 25% reduction is significant because we have to stop the actual production line for about four hours during trial runs. We design about 30 new products annually, so just one less test run saves us about 120 hours every year.” – Koichi Sato, Engineering, Kawai Plastics Industry

Integrated manufacturing workspace

Fusion offers a seamless integration of CAD and CAM functionalities. Manufacturing tasks such as additive manufacturing, subtractive manufacturing, and injection molding can all be performed within the same tool. This eliminates the need for multiple tools and streamlines the overall design-to-manufacture pipeline.

Incorporating DFM principles into the design process reduces errors, costs, and material waste, while improving product quality and efficiency. It’s time to transform the way you work you.

Learn more about Autodesk Fusion