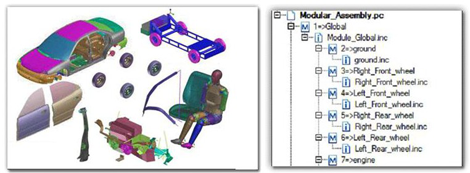

The new version introduces a new modular input methodology

ESI Group has announced the latest release of its flagship software Virtual Performance Solution, which gives manufacturers the ability to evaluate and optimise product performance across multiple domains.

The latest version introduces a brand new modular input methodology, enabling manufacturers to align the structure of CAE models with their CAD or product data management tools.

Further along the process this allows manufacturers to share simulation results and iterate with suppliers responsible for product components; saving time.

By using one central simulation model, or ‘single-core model’ that can integrate all manufacturing properties and multi-domain simulation data, users can efficiently assess trade-off between different engineering domains.

This ability is said by ESI to enable more innovative product design and provides particular benefit for companies who must sustain high product performance as they adopt new, lightweight materials.

Working on the same single-core model from end-to-end enables interactions between departments and supports faster design iterations; contributing to reduced development costs and time.

With the new modular assembly, ESI customers can also use an unlimited number of finite elements for each part, adding model details as required.

Enhancements in the domain of Noise, Vibration, and Harshness (NVH) include new automated simulation processes, which users can customise.

To support the new enhancements, Virtual Performance Solution’s graphical user interface – Visual-Environment and associated processes – now fully supports modular assembly and the common ESI Result File format across all domains.

Model converters now cover most industrial standard third-party programs, while the graphical performance has been improved for handling larger models.