Topology optimisation has been credited with helping reduce the Vins Motors Duecinquanta motorbike’s weight to 95kg, and a mere 85kg for its track sibling.

Vins’ Duecinquanta was designed with the help of fellow Italians Asotech and Ansys’ Mechanical software package, using simulation to iterate the motorcycle’s design, with Ansys Mechanical topology optimisation and fatigue analysis tools key to the project.

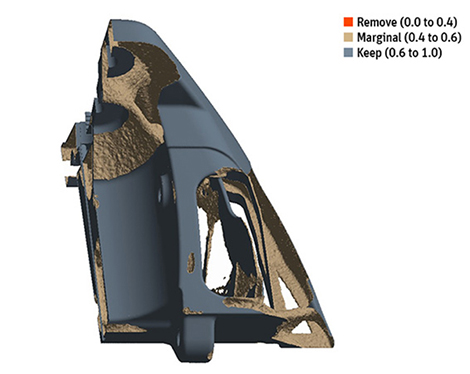

Asotech and Vins started with the Duecinquanta’s frontal node, loading the geometry of the part into Mechanical and assigned it a series of loads before defining areas of the part that needed to remain constant — like connections to other parts.

The team also added an optimisation goal: to reduce the weight while limiting the maximum stress.

Based on these inputs, the software showed the team where material could be removed and how much needed to be kept.

The team investigated if they could cut more weight by tweaking the inputs and using the new part as the next starting point for the topology optimisation.

Topology optimisation of the frontal node shows how much material to remove or keep

When the design team was satisfied with the topology optimisation, they moved on to the important stage of fatigue analysis as they looked confirm that the frontal node’s service life was well within the safety limit.

The fatigue analysis was a good measuring stick and even showed where more material could safely be cut from the frontal node design than they originally thought possible.

The final part weight of this component was reduced by an incredible 10kg

After a few more topology optimisation iterations the motorcycle’s frontal node dropped from an initial 18kg to 8 kg.

With the same approach applied to all the bike’s chassis components, the Duecinquanta sports bike now boasts an exciting power to weight ratio for what is only a two-stroke engine.