Something I’ve been considering of late is the use of specialised design tools. While the majority of systems we look at on a daily basis at DEVELOP3D are general purpose systems, intended to be used by a very wide variety that runs the gamut of industry sectors, tasks and processes.

But what if you’re working in an industry that is both inherently complex and highly specialised. You’ll never be able to find a system that caters to your requirements, both in terms of capability, but also in terms of language – right? It seems not. This is a new series of articles that I’ll be posting that look at some of the specialised design and manufacturing tools out there, tools that are lesser known, but have something to show, something to demonstrate in terms of how to handle a process and how to offer the user something unique. And I’d like to start with something that fills me with complete and utter joy, for reasons which will become apparent. BikeCAD is developed by Canadian outfit, Bicycle Forest and it’s currently on its 6.53 release. To get some background, I spoke to developer and founder of Bike Forest, Brent Curry about where the system came from.

Al Dean: How long has BikeCAD been in existence?

Brent Curry: I’ve always loved cycling, so when I went through the Mechanical Engineering program at the University of Waterloo, in Ontario, Canada, I made a point of serving most of my co-op work terms in the bicycle industry. I started at Vitus Cycles in France and then went on to Syncros Applied Technology in Vancouver, British Columbia (maker of stems and seatposts), Southcott Pty in Australia (manufacturer of mail delivery bikes for Australia Post and importer of GT Bicycles) and Dekerf Cycle Innovations in Vancouver where I got to learn from legendary frame builder Chris Dekerf.AD: Where did the idea for the product come from and how has it grown?

BC: Along the way, I spent a lot of time drafting bicycle frames on paper and on various 2D and 3D CAD packages. I realized that a parametric CAD program specifically designed for custom bicycle frames would be a useful tool. I developed the first version of BikeCAD in 1998. It was just a simple Java applet, but it allowed custom builders to design frames and determine the lengths and angles at which to cut the tubes. I made it available for free on my web site.I’m grateful to the people at Serotta Cycles (http://www.serotta.com/) who contracted me to expand the program to account for paint schemes. It was then that I realized that BikeCAD had the potential to become a commercially viable product. I continued to develop the program into a standalone application that includes various ways of modeling riders on the bike. BikeCAD Pro now features a fully customizable tool called the Fit Advisor which is used not only by custom builders but also bicycle fit specialists.

AD: Any future plans?

BC: I am constantly adding new features to the program. As new versions of the program are released, all owners of BikeCAD Pro receive the upgrade for free. I can’t say what new features will be included in the next update, but I hope to have it out just before the North American Handmade Bicycle Show in Richmond, Virginia on February 26-28.

How it works

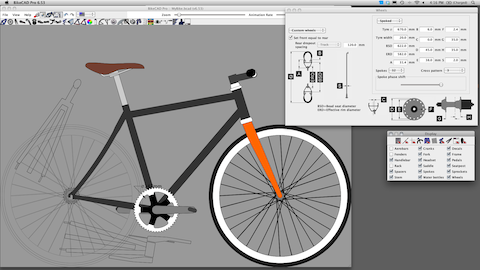

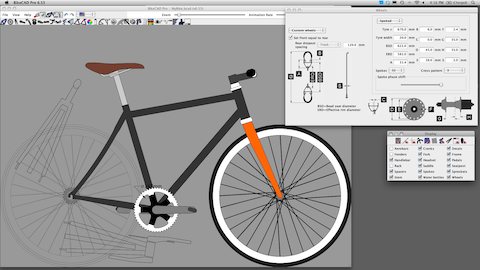

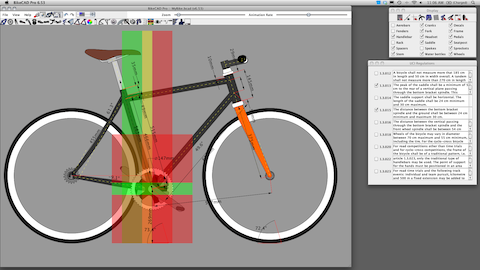

BikeCAD Pro – running nicely on MAC OS X, although Windows and Linux variants are also available.

BikeCAD Pro is a java-based system that is incredibly small in it’s foot print. It’s under 20Mb in terms of a download and because it’s Java based, there are versions for Windows, Mac OS X and Linux. Once you fire up the software (I tested it on my battle hardened MacBook Pro – it worked like a dream). You’re presented with a clearly laid out user interface. Obviously the display is taken up with a preview of the bike you’re working on. Across the top are a series of icons that access the various parameters that go into designing the bike.

Each brings up a clean dialog that allows you to configure the wide and varied options, inputs and parameters that allow you to design the bike you want, often graphical previews when most needed. You work through Frames, Wheels, Forks, Saddle, seat post, Headset, Stem. There’s inputs for the rider form, foot size. There’s inputs for tube size, gearing and sprockets, cranks, chain rings, drop outs and such. Recent releases have seen the system grow with the ability to fully customise not only how your bike is built, but also how the bike appears and the current release gives you very clear and clear visualisations of your current design which can be panned, zoomed and captured for reuse.

Human x Machine

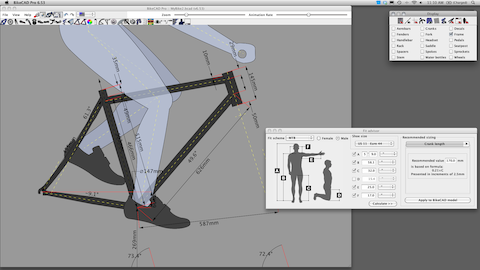

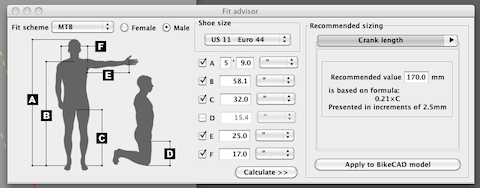

What I found fascinating was the way the system handles the interaction between the human using the bike and the mechanical components. For example, the Fit adviser allows you to input the riders measurements and shoe size. It’ll then calculate the optimal crank arm length, then apply it to the design you’re working on. At any stage in the process, you can load up a human form and inspect how it looks on the current design.

Crank Arm length optimisation

Alongside this, there’s a set of visual checks that allow you to see how the current design conforms to cycle design standards (of which there are many), you’re presented with a list of the most critical checks, select one, then the system shows the limits (many are related to interference between man/machine) so you can see what you’re dealing with.

Shown here are limitations relating to saddle and vertical bottom bracket plane as well as the requirement for the bottom bracket to be within specific limits in relation to the ground.

Documenting the design

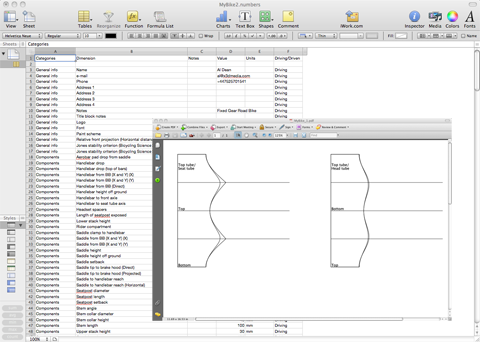

Once you’ve created your current design, BikeCAD Pro then includes a range of tools for documenting the design for manufacture. From creation of dimensioned drawings, 2d renders, miter profiles, dimension listings – all of which can be exported to a variety of formats such as PDFs for drawings, CSV files for lists and tables.

Speciallism par excellence

BikeCAD Pro is an incredibly detailed piece of software that’s been developed in co-operation with its users and with a community behind it and I find it fascinating – it solves a complex design problem in a very efficient manner and perfectly demonstrates how technology can be used to great advantage in an industry that’s very much based on handcraft and smaller workshop (of course, outside of the large global brands of course). It mixes visual design with standards, manufacturing consideration and ensuring that the design you create is both safe and within required limits. Mainstream design technology vendors could learn a great deal from this. If you’re interested (and let’s face it, designers and engineers like bicycles – a lot) in the software, it costs $350 (canadian dollars). There are less functionally rich versions of the software available to try on the Bicycle Forest web-site. Impressive. Highly impressive.

Oh and if you want to know what happens once you use a tool like this, have a watch of this breathtakingly wonderful video from the team at Paper Fortress (formerly quarter Productions) that shows how Geekhouse Bikes builds a frame from scratch (you’ll spot some BikeCAD Pro love in there too).