7 materials are initially available to customers wanting parts printed on the Carbon3D machines by the bureaux

For those of you wishing to get your hands on 3D printed parts from the much hyped Carbon3D CLIP technology, your time has come – with the company announcing four service bureaux have joined its early customer program.

CIDEAS, Sculpteo, Technology House and WestStar Precision now have the first generation of Carbon machines installed, reportedly one of the fastest 3D printing technologies available, with a wide range of materials.

All four bureaux installs are in the US, including French online service provider Sculpteo, which will be running the machine from its California facility. However, all are allowed and willing to ship parts globally.

Speaking with Carbon, the company states that it is currently focused on North American sales, with the hope of further developing the product solution and support for service bureaus.

Carbon has announced that 7 materials will be available from its “diverse and growing selection of materials that enable product designers and engineers to build functional prototypes and production parts”.

Which ones exactly is still to be announced, but the suggestion is that they are all for common engineering requirements: “From the elongation and resilience expected of an injection molded polyurethane elastomer to the temperature resistance of a glass-filled Nylon, and many more.”

Further details on materials are expected in the coming months.

Speaking to CIDEAS president Mike Littrell, a company that boasts a huge range of machines and materials already, it is clear that they expect the Carbon technology to drive new markets, increasingly in end-use parts.

“I believe that the materials that Carbon continues to develop and improve, will drive new vertical markets,” he explains.

“The number of technologies we possess is driven by our customer requests. Initially our automotive, medical and aerospace customers will be able to use CLIP for complex production parts that require unique material properties and the characteristics will be attractive to other markets as well.

Littrell expects that the combination of durability with surface finish provided by the CLIP technology will also bring changes to the design process. “This will likely drive companies into redesigning their products to work with the process rather than the other way around.”

“These new customers are key drivers of innovation and production across industries,” said Carbon CEO and co-founder Joseph DeSimone. “We’re excited to partner with them and offer expanded access to CLIP to further uncover application opportunities for our technology.”

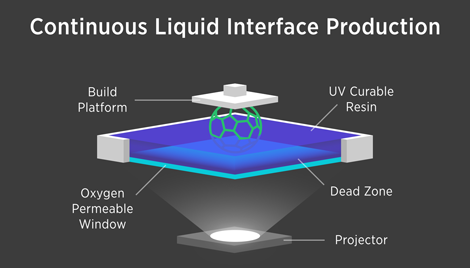

CLIP uses a tunable photochemical process that projects a continuous sequence of UV images through an oxygen-permeable, UV-transparent window below a liquid resin.

The dead zone created above the window maintains a liquid interface while the part advances above.