The Rolo road bike frame, at 710g, claims to be the lightest and stiffest in the world

Rolo Bikes has unveiled its results of a joint development project with Altair, producing a road cycle weighing in at a featherweight 710g.

Using Altair’s HyperWorks Suite, Rolo’s engineers took the design through a process of optimisation and virtual testing with the goal of achieving world leading levels of performance for weight, stiffness and comfort for a bicycle frame.

Beginning with a carbon fibre frame of 829g, by the end of the optimisation process the Rolo frame weighed just 710g, the company showcasing its work at the Euro Bike trade show.

Rolo Bikes had already created virtual test jigs to replicate the European Committee for Standardization (Comité Européen de Normalisation or CEN) tests as well as the Zedler stiffness tests using HyperWorks, and had correlated the 829g baseline frame model to physical tests.

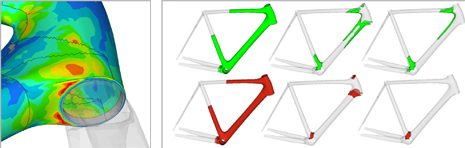

Initial virtual analysis of the baseline design highlighted several areas of concern where the frame was under particularly high stresses. The optimisation process would address these high stress areas in a weight efficient way whilst ensuring a manufacturable design.

To optimise the carbon fibre frame, Altair ProductDesign utilised a three-step approach, during which the shape, thickness, direction and location of each layer of composite material was fine-tuned until an optimum solution had been reached. Each stage was performed using HyperWorks design optimisation solution, OptiStruct.

At the end of this three-step process, HyperWorks was again utilised to analyse and validate the optimised frame against the CEN and Zedler tests. The resulting composite layup created a component that is manufacturable based upon Rolo’s meticulous hand layup construction process, and all within cost targets.

Left: Impact analysis using RADIOSS. Right: Free-size optimisation to define the ideal carbon fiber ply shapes

“We chose HyperWorks for our project because we think that it offers us the most powerful tools for our optimisation and development tasks within one suite,” said Adam Wais, CEO, owner and co-founder of Rolo Bikes, which was founded in Luxembourg in 2011.

“In addition, the use of HyperWorks enabled us to develop our own simulation tools for virtual testing.

“When we realised that we could use additional engineering support and manpower in our development and optimisation process it was a natural choice for us to work with Altair ProductDesign, since the company’s engineers are very familiar with HyperWorks and have tremendous expertise in designing and optimising composite materials.”

As well as achieving its performance target in terms of weigh, stiffness and comfort, the project was also completed in an extremely tight tame frame with close to no prototypes in order to get to to the Euro Bike trade show.