We’ve been known to like a tipple here at D3D, so we weren’t going to turn our noses up at the chance to look at the design of a new luxury vodka bottle.

Unfortunately the bottles were empty.

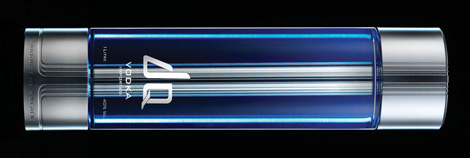

Industrial Design Consultancy (IDC) has just completed the project to develop the luxury vodka bottle with unique design appeal for upmarket brand Nordic Spirit.

Advertisement

Advertisement

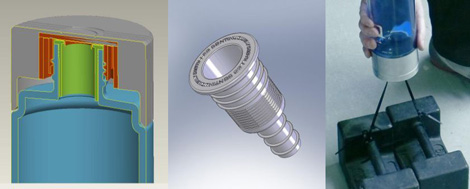

The bung and pourer rendered in CAD, while the prototype hit the heavy weights

- Classed an exclusive ‘super-premium’ spirit, the DQ Vodka is produced in Malmköping, Sweden, where the town’s water is renowned for taste and distillation standards.

- The task was to design a one-litre bottle that reflected desirability, luxury and uniqueness.

- The project involved developing and engineering all the elements of the bottle, whilst making sure that the design could be associated with the rest of the brand’s products.

- IDC developed a sleek, sophisticated design combining glass, aluminium and satin chrome.

- As the vodka is poured, it is drawn through a central shaft and out through a nozzle in the centre of the lid, which enables oxygen to get into the vodka for better taste.

- In designing such an unusual bottle, the team spent time researching different materials and manufacturing processes for the cap and the base, as well as collating samples of potential materials and finishes.

- IDC finalised the industrial design of the bottle, which included graphics, style, material selection, finishing, ergonomics as well as renders in V-Ray for promotional use. It also engineered an effective neck stop and seal for the top cap.

- Styling concepts were worked on in Shark FX, while the final 3D CAD models were created on Pro/Engineer

- In-house IDC Models built a rapid prototype of the bottle cap using its 3D Systems Viper SLA machine; the team also explored the manufacturing alternatives for short and long term production.

The cap and base were prototyped in-house by IDC Models

www.idc.uk.com

www.dqvodka.com

Related articles:

NaviSite introduces Desktop-as-a-Service solution for 3D CAD

Elbow implant design for dogs created through super speed Proto Labs prototyping workflow

COFES Agenda: Clash of the Titans (or my agenda)

Altair AI to be used in PIVOT sustainable manufacturing project

Dassault Systèmes offers education platform via the cloud

CCE updates EnSuite ReVue adding 3D audio notes

Inside the mind of an inventor: ‘Tom’s Fantastic Floating Home’ on TV screens st

3D Systems and Ems-Griltech launch DuraForm PAx