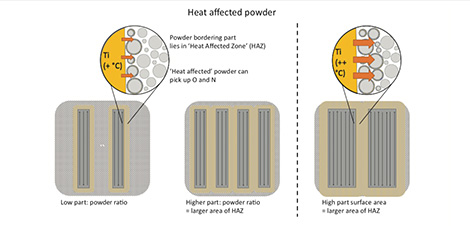

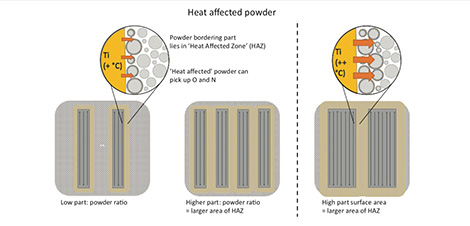

For anyone investigating the world of advanced manufacturing materials, the world of 3D printing powders for Selected Laser Melting (SLM) will be of great curiosity – with quality of parts directly impacted.

Producers of SLM powders, LPW, has launched an in-depth guide and research study, including 14 case studies that cover everything from powder degradation, flow after recycling, laser diffraction and even the evolution of oxygen within powders.

It’s in-depth, educational, and it might just adjust your thinking about what you’re throwing into you additive manufacturing workflow.

Read the case studies here.

Related articles:

Lenovo now reseller of Varjo headsets

Nintendo Switch opens designers thoughts to customised controls

3D Systems shrinks pellet-fed EXT 800 Titan 3D Printer for design prototyping

Dell Precision 7865 launches with AMD Ryzen Threadripper Pro

3DExperience World reduced to online only event

Hipsters x Pizza = Fixie pizza cutter

Autodesk 3ds Max 2021.1 update

Mother Lode of new jobs from Mamas & Papas