Silverside Detectors, a developer of next-generation nuclear radiation detection technology for the defence and homeland security market, has spoken about its design processes and its choice of CAD software.

The company’s neutron detectors are used for large-area and standoff detection operations, and are designed to maximise the neutron sensitivity and go beyond the US government-set performance standards.

Silverside VP of hardware engineering, Philip Taber, said that part of its choosing Onshape’s Cloud-based CAD for its design and engineering was based on the need for help with data management. “With our previous CAD system, we’d have engineers trying to figure out which version was the latest version of a design.

“With separate files for the front, back, the side plates and the base, each part would get a letter and number code so we could try to keep them straight, but they’d get all mixed and matched.

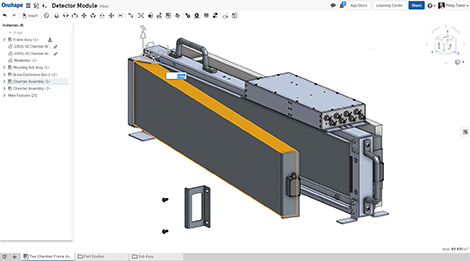

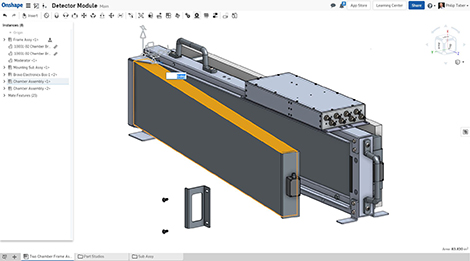

Silverside’s Li-6 neutron detectors are billed as the next-generation of technology for sensing nuclear material, with a modular detector design allowing plug-and-play integration in a range of detection systems, from ports to vehicles to backpacks.

Taber added that its design process has been almost halved because the design team can work on parts together in one place, versus flipping back and forth between files.

“We can make changes without worrying about breaking the assembly,” he said, advocating the In-Context Design feature, which allows engineers to edit parts in the context of a higher-level assembly without them changing unpredictably due to motion.

Developed with funding from the Department of Defense (DARPA), Silverside is creating new products for both security markets and neutron research applications from its base in Cambridge, USA.