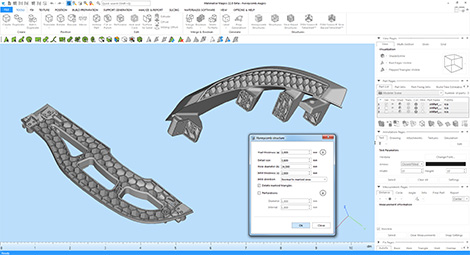

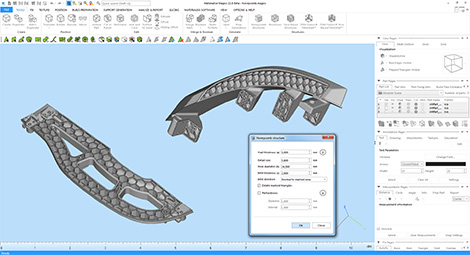

New honeycomb feature in Materialise Magics 22

The new updates to the Materialise Magics 3D Print Suite, including Magics 22 and Inspector 3, look to speed up the 3D printing workflow while tailoring it for industrial levels of output.

Magics 22 includes new design features such as the honeycomb structure, which reduces weight without sacrificing strength, and the shelling feature that reduces a part’s material consumption without changing its functional design.

Improved workflow and design optimisation tools offer an increase in speed and a reduction of material consumption, while the new version promises the user faster generation of metal support structures, create denser laser sintering platforms, and the ability to fit more parts on stereolithography, DLP and FDM platforms.

“Smoothness in the data prep workflow has been mentioned by beta testers as one of the biggest benefits of this new version,” said Materialise senior product director Thomas Moens, quoting time-saving enhancements in the Sinter Module which resulted in a speed increase of 20 per cent on 3D nesting and “around half an hour per build on multiplatform nesting”.

Materialise Inspector software, for defining the best machine parameters for a build, aims to limit the number of iterations needed to print good parts and reduces the time and material spent, with the new version allowing for online error detection, which means that the software analyses build images in real time and the machine operator can immediately stop the build if errors occur.

“The combined functionalities of Materialise’s inspection and simulation software for Metal AM provide the missing link to bring 3D Printing into manufacturing environments. Once your parameters are tuned and validated, you can automatically validate the quality of your production parts throughout the different production stages,” said Tim van den Bogaert, Materialise senior director of new business.

“Materialise is focusing on bringing automated science and physics-driven tools to help users run their production environment as reliably and efficiently as possible. Simulation will play an essential role in this”.