Link3D’s new Post-Processing Management and Work Plan attachment

Aiming to assist organisations streamline manufacturing processes with work plan sequencing and quality management solutions, Link3D has launched a new Post Processing module for additive manufacturing..

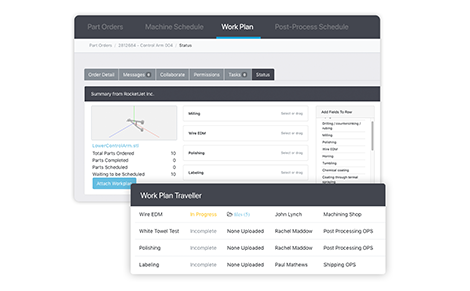

By designing and attaching work plans that are templated for each part order within an assembly, representatives that are processing parts for post-production will be automatically notified once work is in their queue.

Detailed post-processing information will include responsible parties and descriptions and/or checklists for each step in the development of the part.

The interface includes drag-and-drop, Kanban, Gantt Chart and List views to give facility users a 9 foot view and 9 second view of their production schedules. Allowing technicians to trace and track their activities from beginning-to-end with built-in quality management solutions.

Link3D co-founder and CTO, Vishal Singh, said: “With dynamic routing and smart scheduling algorithms, Link3D aims to drastically improve the operational efficiency of additive production, particularly for OEM’s looking to adopt series production.

“Furthermore, capturing and tracking data at each stage creates the perfect platform to enables data-driven automation.”