Mantle has announced the launch of its metal 3D printing technology developed specifically for toolmaking as it looks to simplify how mould tool components and inserts are made and accelerate the process.

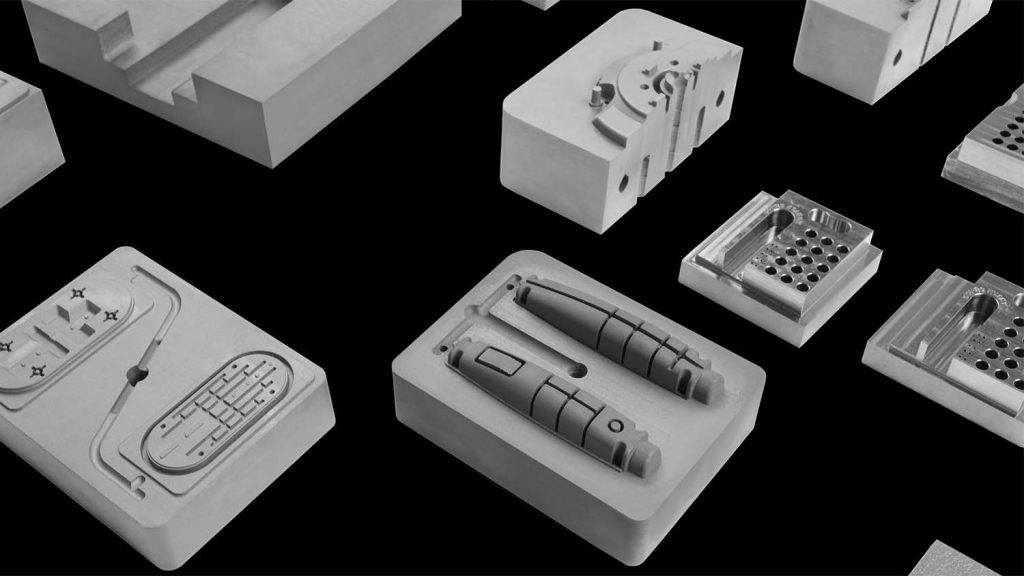

The Mantle P-200 printer is a hybrid system with a build volume of 200 x 200 x 150mm built on a CNC platform that integrates a paste-based 3D printing process and machining to produce parts with the necessary accuracy and surface finish for tooling, while allowing for conformal cooling channels to be built within the product.

Two tool steel materials, H13 and P2X (a steel comparable to P20), are available at launch, which Mantle claims as ‘durable, stable, and perform like traditional tool steels’ with secondary operations like machining, polishing, coating, and laser welding all possible.

The F-200 furnace is necessary to sinter parts from the printer, with one furnace able to sinter multiple parts and support multiple printers.

Mantle has also released software that helps automates the printing process, including the generation of all toolpaths and machine instructions.

The solution has been designed for ease of installation and use, targeting the massive skills gap that’s appearing in the injection mouldmaking industry, which is helpfully also a $265 billion global market.

Fellow Beta testers Fathom Manufacturing, one of North America’s largest on-demand digital manufacturing platforms, claims it reduced its toolmaking time from 200 hours to 110 hours by eliminating or reducing several operations, including CNC milling, EDM, and polishing.

Further tester statements include Tessy Plastics, a global contract manufacturer that surpassed 1.25 million cycles on a production mould built with Mantle components. The mould, which makes deodorant packaging, contains both Mantle H13 and P2X tool steel components and demonstrates the durability of Mantle’s steels in a demanding production environment. Tessy Plastics also realized a time savings of 60 per cent, from 150 hours to 60 hours.

Delivery of the first production systems is planned for the first half of 2023, for a reported price of $350,000.