Sochi 2014 cross-country skiing gold medalist Dario Cologna is a big fan of Odlo’s underwear

In the midst of our brief London summer (a two-week ‘heatwave’ before going back to cloud and rain) its hard to imagine an office of busy little Swiss people designing performance sportswear for the depths of winter.

Established in 1946 in Norway, and a Swiss company since 1986, Odlo is the European ‘leader in sports underwear’, a much fought for title, and is proud of its technological innovation in this area.

Providing world champion cross-country skiers, alpine skiers and other snow lovers with specialist under garments, to develop its design process further it has taken on Lectra Modaris 3D software, giving it the upper hand when delving down below for form and fit.

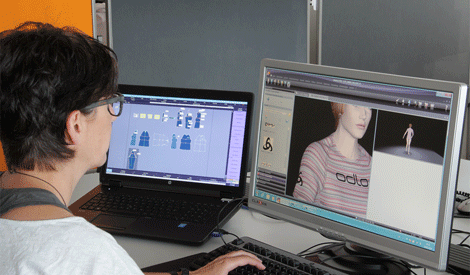

Modaris 3D at work, helping to form the shapes and patterns needed for complex fabrics

The company works with a vast number of varying fabrics, with different properties – systems are sewn into garments to offer support to the wearer, fabrics are woven in special ways to maximise heat retention or cooling.

The full list of variable materials they use means they can produce exactly the right garments for the situations needed.

Pattern complexity and the special fabrics Odlo use make sportswear prototypes very expensive, so it is using the 3D CAD to cut development costs and lead-time by reducing the number of prototypes it produces.

Another benefit is the improved product visualisation before physical prototypes are available, allowing marketers to make earlier, more accurate estimations.

Currently Odlo produce two collections per year and are present in 20 markets. With the addition of the new abilities of Lectra Modaris 3D it hopes to further move into the sports outerwear market by developing versatile sportswear to the same standard as their underwear, but that can be worn as fashion items.

Ulrike Froitzheim, head of quality management and 3D project manager, explained: “The unique fit requirements of a sports garment need to be respected, as well as demands for sun protection, breathability, elasticity, and resistance to water and wind.

“The pattern for a pair of bike shorts, for example, is designed specifically to support the athlete in a seated position.

“Not everyone can interpret 2D sketches in order to understand the final product; 3D gives us a way to visualize the product,” says Froitzheim. “Better communication and better understanding will help us make better decisions.”