#3: Looking at this initial Tech Preview, Inventor Fusion has some legs to it. Yes, there are things missing or that it doesn’t do in comparison to other direct modelling systems – in fact, the system is installed with a list of things it can’t do, so if you have problems, check that first (it’s in the README_INV_FUSION.htm file).

But perhaps the real thing to consider is in the title, the word Preview. After all, this is a formative release of a new technology. So, to get an idea of where this is headed, I got on the phone to Kevin Schneider who heads up the Emerging Products and Technology Group at Autodesk, the man heading things up and pushing the system forward.

Al Dean: For me, the big question is the round tripping between Inventor and Fusion that you showed at launch. That’s not in this release is it and have you got any idea when it’ll be available?

Kevin Schneider: That is not in technology preview 1. We intend to let customers look that later this summer in an update to the Technology Preview. Not in the first Tech Preview but making it clear that we’re going to keep refining the ideas over the year, with customer feedback. As a result, the round trip with Inventor is not in this preview but we will get a chance to have customers try that soon. When we announced it, we should have been a little clearer that this wasn’t going to be there in the first release.

AD: How many releases are you looking at? Is there a specific lifetime you have for this thing on labs or are you looking at when it might ship?

KS: The technology preview you’re working with will go on to the end of the year. I can’t predict future releases or much about that but what I can specifically say is that we’re going to continue to update the Technology Preview releases as frequently as soon as we can implement ideas that come from customers. As to when it ships, that’s a bit more of a complicated question. Just like we did with Plastic Parts and the Advanced Simulation preview, ultimately the destination for these capabilities is core Inventor. What I would say is that customers need to tell us when they think what we’re previewing is ready and then we’ll move it to Inventor. That’s the whole point of doing a technology preview.

AD: It’s never going to a standalone application as it is at the minute, it’s always going to be an integral part of Inventor?

KS: I think the most wide reaching impact of the technology you see here will be when it goes into core Inventor. Whether the tool you’re using has a future – we have no comment or no commitment at this time. I think you’ll agree that if this capability was in Inventor, that would be big. Really Big.

I think the thing that’s important but is sometimes a little confusing, is the reason that we do these Technology Previews as a separate application is that customers are very reluctant to use Beta software because they have to uninstall production software, the data doesn’t migrate, they accidentally overwrite production files – all these things can be really dangerous in a production environment.

But by doing these as separate executables, you can side-by-side install, you can install it at home. We’ve found a much larger number of customers are using these things when we take the risk away from production software and we get way more feedback earlier in our ideas. It’s better for our customers, better for us, better for the industry.

AD: The one thing I’ve been thinking about is that you guys use your Labs web-site and resource a lot more than many other vendors. It’s a nice thing that you put these things out and you seem to engage with your users a lot more. is that something you’ve thought about? I’m curious about the mix up, when you’re developing something new like Fusion, do the customers that use it throw you things you didn’t expect or do you have a good idea where things are headed?

KS: I can give you some examples. We thought that some of the progressive shelling we’d done (Editor’s Note: this is found in the Plastic Part design tools) and as you know, work I’ve been doing for years. When we went to the technology preview and we got customers working with it everyday, we learned a lot and a lot of it about being not as easy to use as the benchmark we have set with Inventor. And that’s why it didn’t show up until Inventor 2010, because we needed to do more work.

In the past, that would have gone into Beta, people would have looked at it and it would have shown up in the release and users would look at it and think “What the heck is this?” – it would have been another hacked piece of functionality that customers get annoyed with. We’ve eliminated that problem by using Labs get quick feedback.

To specifically answer your question, there was a quite lengthy discussion at the last Paris press event between Roopinder, Martyn and a couple of others about how Autodesk doesn’t do enough to preview new technology, engage customers more early. “To lead” was the challenge they were giving us. Now the group I work, emerging products and technology, was a direct response to that can Autodesk do to use Labs better than any other company we’ve seen so far to get ideas and technology into customer’s hands early enough so we have solid ideas about how these need to go into our production tools.

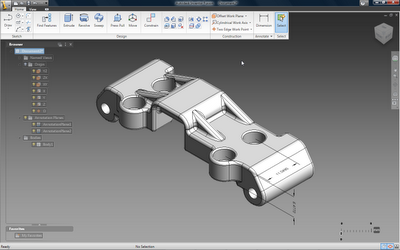

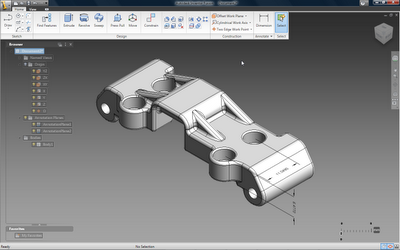

First thoughts on the Technology Preview 1

I’m in two minds about what to write in the way of a conclusion. After all, this is very early stage software, nowhere near production ready. Autodesk has built a set of technologies (delivered as a standalone application) that’s clearly being used to knock the rough spots off the technology and usability before it gets anywhere near integration into core Inventor (which is the eventual goal). So let’s strip it back to basics and look at what Fusion represents.

The most immediate thing is that it brings a number of direct modelling tools that allow you to work with geometry in an effective manner, regardless of source. Yes, the tools available follow the conventions of other systems operating in the same, direct modelling manner and as a first pass at getting the technology out there, it’s clear there’s potential here. Great potential indeed. Direct modelling, despite what some vendors claim, is a technology that’s very nicely suited to specific tasks. Not in terms of industry or market sector, but pure, hardcore modelling operations where history-based systems fail. Whether that’s working with imported, dumb, data or whether that’s making design changes at late stages where the history of the part or assembly becomes unwieldy and prone to breakdown. It also provides an interesting way for the non-expert CAD user (but I’d stress the experienced engineer or designer) to get ideas down, play with geometry and to think, in true three dimensions and document those ideas and concepts – but without the knowledge overhead traditionally associated with history-based modelling techniques.

These have been the sweet spots for direct modelling for the last two decades and I suspect might always remain so. What’s changed is that there are larger vendors now jumping into the space that’s formerly been occupied by the likes of CoCreate, IronCAD. If you have bigger players discussing a technology, there’s a perception that something new has been discovered. Facts are that direct modelling isn’t a particularly new concept. What’s changed is market awareness, increased development resources across the industry and yes, more powerful hardware to enable those direct edits to be made with less chunking of a processor set.

But alongside the direct modelling, there’s something else afoot here and that’s an intriguing experiment or testing of waters with regards the Inventor user interface. Inventor often gets a bad name for itself amongst users moving to it from other modern systems (in all honesty, usually, SolidWorks), claiming it’s not as easy to use and my personal thoughts are that there’s one or two very fundamental sticking points that back it up – nothing major, but things that jar if you’re used to other systems. Looking at Fusion and separating the modelling technology from the user experience, it’s clear that Autodesk is testing out how users react to the new marking menu system, a much more interactive heads up way of working than is currently implemented in core, shipping Inventor. What I find intriguing is that Autodesk are doing this by release code into the public realm and letting users (whether they’re customers or not) play with it and see what it can do. That can’t do anything other than assist with making a better product.

So the two in combination makes for an interesting thing. Some new technology that’s at a very formative stage, still awaiting some of the core components (the round tripping) and which is going to extend well beyond this calendar year with updates and such, then Tech Preview 2. Let’s see where it goes.

If you fancy a play, then its there to have a go with. www.inventorfusion.com