A Fit Station foot scanner

HP is driving its Multi Jet Fusion technology hard as a production-ready commercial 3D printing system, and today it has made further announcements, on top of its most recent partnership with Deloitte, to show that it means business.

Fit Station is aimed at disrupting the footwear retail market, forming an end-to-end solution for scanning a customer’s foot, designing an insole around its unique walk and run pressures, using the data to suggest suitable off the shelf shoe types, and combining this all with a 3D printed custom insole.

Meanwhile, HP has reinforced its partnership with Siemens NX, launching its new AM for HP Multi Jet Fusion software module, officially certified by HP for production-scale industrial 3D printing.

The Fit Station retail scanner uses HP technologies to analyse each foot using a combination of 3D scanning and pressure plate technology to deliver a dynamic gait analysis for the individual, before the data is used to manufacture an insole using the Multi Jet Fusion 3D printer.

Additionally, the data in the future could be used to transform shoe midsoles, providing specific hardness zones and volumetric fit for PU injection moulding.

HP is piloting the platform across 11 select US stores, and across several of the 4,000 global locations where insoles partner Superfeet has a presence. Steitz Secura, a specialist in safety shoes manufactured in Germany, has also signed up to use FitStation to aid in its focus on comfort, preventative health and safety.

“For 40 years, we have set the standard for shape and fit. Until today, the technology to deliver a 3D printed insole that meets Superfeet’s exacting standards didn’t exist,” said Eric Hayes, CMO at Superfeet.

“Our new solution allows us to create the most individualised shape and fit on the planet.”

A spokesperson for HP added: “Consumers are not the only one who will benefit. This new technology has the potential to revolutionise the footwear industry by disrupting the usual supply chain.

“FitStation enables local on-time manufacturing, allowing retailers to sell products they don’t have to keep in inventory. With FitStation, retailers can anticipate less product returns by providing customers with proper fitting shoes, based on comfort and function.”

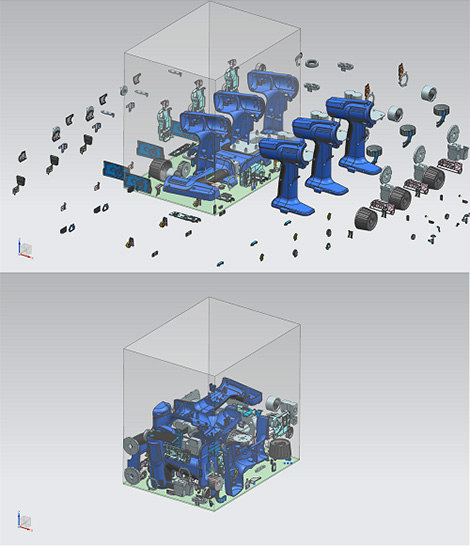

Part nesting for HP MJF printers is now a part of a dedicated AM module in Siemens NX

Away from footwear, Siemens’ new software module will enable NX customers to combine design, optimisation, simulation, preparation of print jobs, and inspection processes for HP Multi Jet Fusion 3D printed parts in a managed environment.

Users should be able to load multiple 3D part models into NX, and auto nest and submit them to an HP 3D printer, all in a single environment and with a minimum of steps.

The NX and Multi Jet Fusion integration also eliminates the need for data conversion between software applications or process steps, which in the future, HP says is intended to allow unprecedented control, including ‘material characteristics down to the individual voxel-level’.

This would result in the ability to print parts with variable textures, density, strength and friction, as well as thermal, electrical, and conductivity characteristics.

“HP and Siemens are bringing together the best in design and manufacturing workflow software for the best in 3D printing, unleashing a wave of new product possibilities with the speed, quality, and economics required for the modern digital industrial era,” said Michelle Bockman, global head of HP 3D printing commercial expansion and development.

“We look forward to collaborating with Siemens to continually raise the industry bar on what’s possible for customers with the voxel-level design capabilities of our Multi Jet Fusion 3D printing solutions.”