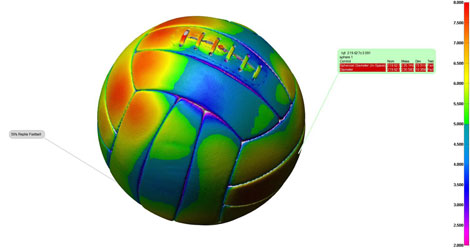

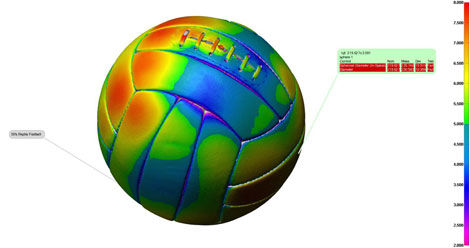

Football from the 1950s: not exactly round

As a fan of the beautiful game, it makes me feel a bit sick to use the word ‘soccer’ in the headline. The thing is I don’t want to confuse our American readers as this whole post is about how perfectly round a football is, and American footballs aren’t, er, exactly round. Now having probably insulted our friends from over the pond, I’ll get on with the story.

Application Engineers at Phase Vision have used their latest scanning technology to scan several footballs to see how round they are – three match quality balls from Nike, Umbro and the current Adidas Jabulani World Cup ball – plus a cheap replica of the world cup ball, and a 1950s match ball – the type some of us remember from our childhood that literally took your head off when it got wet.

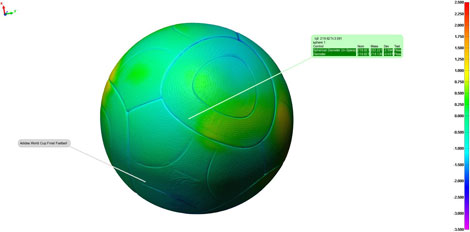

Adidas Jabulani World Cup ball: perfectly round

According to Phase Vision, FIFA regulations specify that a ball must be measured using 16 points, but that masks the true sphericity (or otherwise) of the ball. The use of only 16 measurement points was dictated by mechanical measurement approaches (using a contact arm or co-ordinate measuring machine) which were slow, and which distorted the ball during measurements.

So just how round were the balls? Only three of the balls scanned passed FIFA’s geometry tests for sphericity and size – the three world cup balls, including the replica ball.

Here’s the full story. It makes for an interesting read for fans of football, soccer and even those who made an art out of forging sick notes at school.

The balls were scanned with a Phase Vision Quartz 800DBE scanner, providing millions of measurements – each with an accuracy of a dozen microns or so. The results were displayed graphically, colour-coded to show tolerance to a perfect sphere – all the scans are normalised to a 6mm range in diameter.

The Umbro ball (an England match/ training ball from 2007) was significantly under-sized, suggesting that it may require a higher pressure – or it may have been exposed to poor storage conditions which resulted in shrinkage of the ball. This ball was too far from the nominal specification to perform much analysis – probably an unfair test of this ball, as in this condition it would have failed the FIFA tests for a match-grade ball.

In contrast, the size of the Nike match ball (developed for the 2008 European Championships) was far closer – but again, it was out of specification. In addition, this ball’s stitched structure provides manufacturers with the ultimate challenge – how do they get the bladder in when it is stitched from the inside? The scan clearly shows the compromises that are made in a ball of this type – the ball is not particularly spherical. Several panels are placed on too large a diameter, while other panels are obviously too small. Despite these visible issues, sphericity passes the FIFA definitions of roundness; the ball is however out of specification on diameter. Again, this may be down to storage, rather than an issue with the original manufacture of this ball.

The scans of the Adidas World Cup ball show a far rounder ball, reflecting the newer manufacturing processes used. Even the replica ball has excellent sphericity – although this is an unused ball, and it is unlikely that it would retain this near-perfect shape through FIFA’s stringent tests. The replica World Cup ball did not have the aero grooves and nubbins which made the Jabulani so special, and is unlikely to have the structural integrity to retain its shape through anything more than a kids’ kick-about. However, it is significant that the only balls to pass the more stringent testing that Phase Vision applied on both the roundness and sphericity tests were the Adidas balls.

By way of contrast, the final ball scanned was a 1950s match ball. Scanned at the same resolution, it shows the progress football has made in the last 60 years. Many panels are several millimetres adrift from their ideal position – reflecting the cruder materials and manufacturing processes used.

Clearly the techniques of aerospace and automotive have much to offer the sports industry, and the time has perhaps come for FIFA to consider more advanced measurement techniques for footballs – given the sort of measurement capability which is now readily available. After all, the actual performance of the ball will only be guaranteed if the final produced item adheres precisely to the intentions of the design team. And, no matter how accurate the design and development work, any imperfections in the finished ball could lead to unpredictable behaviour in flight – and ultimately affect the entire destiny of a tournament.

England’s Rob Green can’t really blame the Adidas Jabulani World Cup ball for not being round