Formlabs has launched a two-piece post processing system for desktop SLA 3D printers, the Form Wash and the Form Cure, but despite these products being at the often overlooked end of the process, we’re excited to hear about their development.

As we’ve pointed out before, the rise of the desktop level SLA machine is undoubtedly a good thing – the resolution on most machines is amazing, there’s a vast range of resins available to provide you with the mechanical, aesthetic or downstream performance requirements you want – but it’s a messy business, for a couple of reasons.

The first is that we’ve talking about light curable resins. Whether you’re using a system that uses cartridges or whether it’s a manually filled tank, you’ll see your model, in fine, crisp detail emerge, but after that moment of wonder, you’ll be stuck with all of the remaining resin, both on your part and in your build chamber.

Once you’ve extracted that part (usually fixed to the build platform), you’re going to need to do a couple of additional things.

The first is to wash away the excess resin. This has to be done quickly and efficiently – exposed to light will cause that excess resin to start to solidify and spoil your model.

This is typically accomplished in a bath of 30/70 water/isopropyl alcohol (IPA) liquid. Some vendors provide you with a set of tanks (think; Tupperware – in some cases, literally), some will provide you with guidelines on what to do.

Once the part is rinsed, you’re left with your model as intended (probably including supports). While the light (delivered in whatever manner and at whatever wavelength) will solidify your part, for the most part, you also need to post cure it.

An alternative is the UV steriliser – common-or-garden devices usually found in beauty salons and available plentifully and cheaply on-line or in your local supplier.

Some inventive folks have been home-brewing their own, with a strip of UV LEDs, a box and a turntable (we particularly like the person that strapped a table to a rotary timer to give the model a controlled rotation).

At the high-end of the spectrum, devices are available that perform both of these tasks in a very automated manner, but these, being specialist equipment from the older guard in 3D print, will cost some serious cash.

Formlabs works its magic

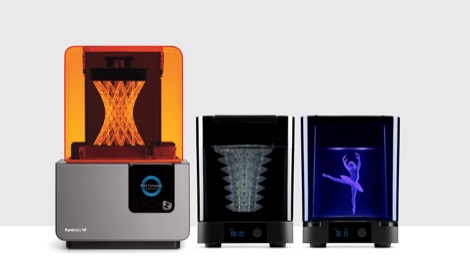

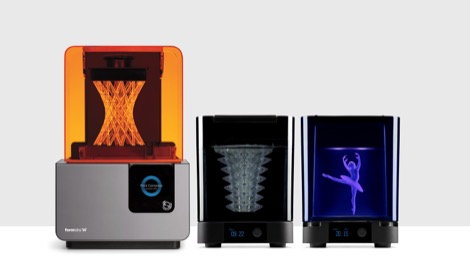

Formlabs has taken this to heart (and as they’ve sold probably more desktop SLA machines than anyone else, probably based on a LOT of user feedback) and developed a brace of devices that are intended to sit alongside their own Form 2 machine and do much of this work for you.

The first, the Form Wash, is an automated system that lets you drop in your model, including your build platform, into an IPA tank, set a time and leave it running.

The machine keeps the IPA circulating (with an impeller in its base) so it’ll get your excess resin out of all of those nooks and crannies much quickly than simply dunking it in a tank.

Interestingly, the machine also includes a hydrometer that will tell you when the balance of your rinse media is heading towards more resin than IPA) and tell you to change it.

Once your parts are rinsed and ready for curing, you then break them away from your build chamber (and if required) remove the support structures and pop them into the Form Cure.

This is a curing device that bathes your part in the required wavelength of light (that’s 405nm for the detail oriented folks) and provides a subtle heat to the part too. It’ll rotate the set of parts so they get equal exposure during that curing process.

As you’d expect, Formlabs has also built an interesting and widespread set of knowledge about its range of resins, so each of these devices comes with resets and suggestions for each of Formlabs’ own resins to give you the best properties for which each is intended.

Now, down to brass tacks – how much do these cost? The answer is simple. The Form Wash is €499 while the Form Cure is €699. €1,200 sounds like a lot, particularly when you consider that the Form 2 printer only costs a couple of grand more.

The reality is that these are two well thought-out and well-designed products that compliment not only the Formlabs machines but the raft of other desktop SLA machines out there.

While I doubt they’re going to replace the hacked together/repurposed devices that do the same, if you’ve got the budget, then they’ll make the whole process not only quicker, but a lot less risky.

SLA resins are, in most cases, pretty nasty materials to work with. Anything that reduces the potential for contact with your bodily parts (skin, eyes, lungs) is a good thing in my book.

They’ll be available to pre-order today from formlabs.com/tools/wash-cure/