The XM200S and XM200C machines from Xact Metal both offer a 127 x 127 x 127mm build chamber for metals 3D printing, and are now available in the UK via reseller Laser Lines.

Operating out of Penn State University’s Innovation Park, Pennsylvania, the Xact Metal technology is aimed at customers in high-performing industries where high-throughput and print speed is critical including aerospace and medical (XM200S), and for entry-level operators, universities, prototyping laboratories and SMEs (XM200C).

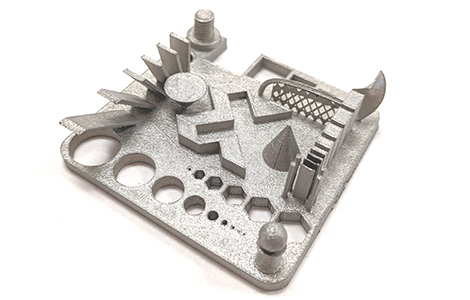

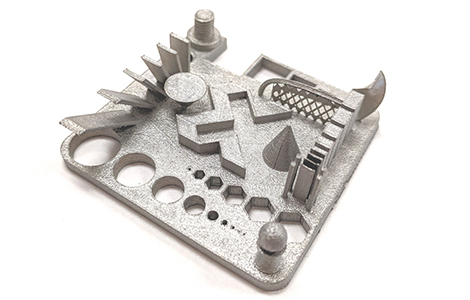

Both systems use a laser-based powder-bed fusion technology in which a laser selectively melts thin layers of metal powder to create parts directly from a 3D CAD model.

An excited Laser Lines sales director, Mark Tyrtania, said: “Making quality metal printing accessible requires innovation.

“Xact Metal’s printing technology is built on the patent-pending Xact Core – a high speed gantry system platform where light, simple mirrors move quickly and consistently above the powder-bed on an X-Y axis.

“It’s another step change for our industry and opens a whole range of exciting opportunities.”

Both machines offer a touchscreen display, which makes it easier to control print jobs, change print settings, and keeping an eye on measurements such as the chamber temperature and oxygen percentage and pressure.

Supporting Stainless Steel, Super Alloys, Tooling Steels, Aluminium, Titanium and Bronze, the Xact Metal machines are able to make parts in a fraction of the time that it takes with traditional casting, while the open platform means that qualified users can develop their own printing parameters or use their own powder.