For many years now, we’ve been told of how aircraft manufacturers are using 3D printing technology but it’s not often that you get a specific user story that details where and how the technology is being used.

A couple of weeks ago, Emirates issued a press release (interesting that it didn’t come through a vendor), detailing how it is using Selective Laser Sintering (SLS) for in-cabin display surrounds as well as conducting trials with the same for cabin air vent grills.

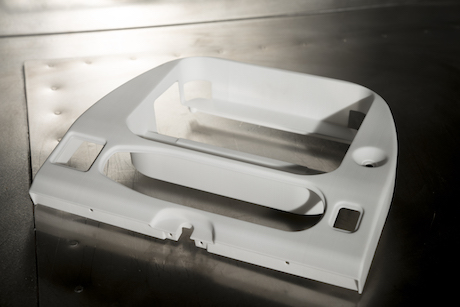

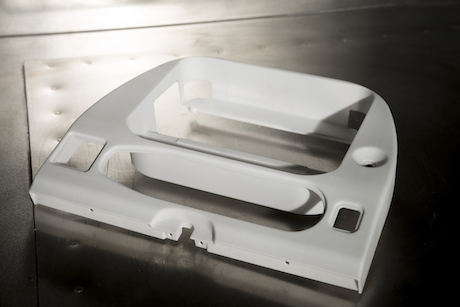

Emirates has worked with 3D Systems and with UUDS, a European aviation engineering and certification office and services provider, to print the first batch of video monitor shrouds using 3D Systems’ Selective Laser Sintering (SLS) technology platform. The material used to print Emirates’ monitor shrouds is a new thermoplastic developed from 3D Systems (Duraform ProX FR1200) which has both the surface quality and the flammability resistance required for commercial aerospace business applications.

Interestingly, not only are Emirates looking to dodge the costs of tooling up for these parts, reduce inventory and have a more on-demand supply chain, the sintered parts are lighter than a traditionally injection moulded component (between 9 and 13% lighter in fact).

That might not sound a lot, but when you consider saving weight in the airliner business means saving fuel on every single trip and each of Emirates airliners has between 350 and over 500 of these things on board, the weight savings are immediately measurable, particularly when you scale it up over the entire fleet.

Of course, there are also many legislative requirements for anything that flies on a commercial airliner, particularly in the cabin. The display shrouds have undergone “a range of structural, durability, flammability and chemical tests and are also in the process of receiving EASA certification for airworthiness for aircraft interior cabin parts.”

On receiving EASA certification the video monitor shrouds will be installed on select aircraft in the Emirates fleet and will be tracked over the following months for data collection as part of tests for onboard durability and wear and tear.

“Over the last two years Emirates Engineering has been actively exploring 3D printing for aircraft cabin parts as it is a transformational technology that can be used to achieve an increase in efficiency and productivity,” said Ahmed Safa, Emirates Senior Vice President- Engineering Support Services. “We worked with a number of suppliers to develop prototypes of 3D printed cabin parts but ultimately decided on working with 3D Systems and UUDS. The technology we use has the potential to deliver cabin parts with reduced weight without compromising on structural integrity or cosmetic appeal.”