Dassault Systèmes, French consulting firm Capgemini and energy giant EDF (Électricité de France), have the signing of a long-term partnership agreement for the future of EDF’s nuclear engineering and its wider ecosystem.

The partnership aims to support EDF in the digitalisation of its plant engineering projects with the view to strengthen plant performance and overall competitiveness of nuclear power. parties describe the deal as representing “a major step in accelerating the digital transformation of the nuclear industry as a whole”.

In keeping with the terms of the agreement, EDF and Dassault Systèmes are engaging in a 20-year partnership that will sustainably support industrial projects using Dassault’s 3dexperience platform.

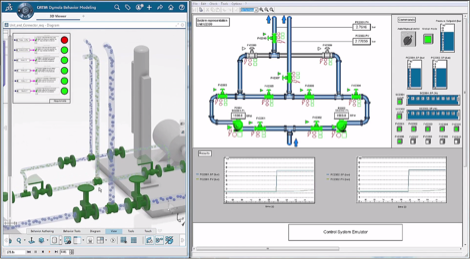

According to the press release, this ‘interactive and evolutive’ platform will be used by nuclear businesses to access real-time project data. It will also be used to design the digital twins of nuclear plants whether they are at the design, construction or operational phase.

Capgemini, teaming up with Dassault Systèmes, will provide consulting, technology and systems integration services, while together the three companies will develop and integrate digital solutions that respond to specific needs for nuclear engineering.

Interestingly for those engaged in the UK power industry, the controversial Hinkley Point C project is referenced explicitly, along other ”future EPR projects”.

EDF Group CEO Jean-Bernard Lévy, said: “EDF’s nuclear engineering function has embarked on a digital switchover process seeking to align us with best engineering practices for complex projects.

“This undertaking, which is key to the success of our future nuclear projects, is a concrete illustration of the EDF Group’s transformation, initiated within the scope of our CAP 2030 strategy.

“We are proud to be supported by reliable and highly respected partners like Dassault Systèmes and Capgemini, who are able to support us over the long term, understand our requirements and help us to co-construct a project engineering process.”