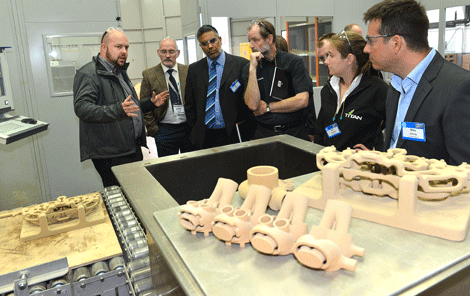

Anthony Middleton of Grainger and Worrall shows explains the intricacies of 3D core printing

Far from the traditional image of a castings manufacturer, Grainger & Worrall (G&W) is working with some high end digital tools to provide bespoke prototyping solutions using rapid-tooled and tool-less digital processes.

One of the only independent UK casting business to employ in-house ExOne 3D sand printing and CT scanning technology as part of its rapid prototyping process, G&W is using these technologies to enable projects like fully-machined engine cylinder head development in less than six weeks.

Sand castings have been used in lots of different industries, the bronze age and the iron age, for example, wouldn’t have got far without them, but the modern version relies on complex metallurgical and chemical interactions, thermo and fluid dynamics.

//www.youtube.com/embed/LFGnjkoeDng?rel=0

Constantly tackling new challenges, G&W’s kept busy by regular rule changes to motorsports and everyday automotive manufacturers – latest pre-production prototype engines always have to be lighter, more powerful, and more reliable than the last – so its designers and engineers work within its customer teams to ensure the production casting and process develops simultaneously.

Key to this is G&W’s digital tool set, working with ExOne’s 3D sand printers to produce the moulds, 3D scanning to provide model data for reverse engineering or inspection of final parts, as well as CNC machining for more traditional tool cutting.

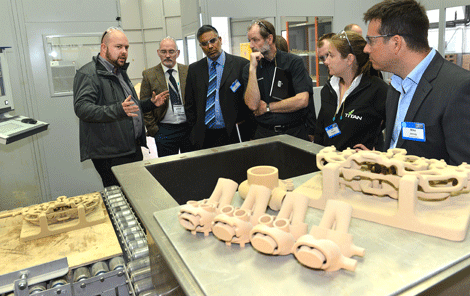

Producing moulds and cores for sand casting is an important part of Grainger & Worrall’s manufacturing process, whether by traditional tooling (shown here) or 3D printed sand

Depending on the product production requirements sometimes sometimes they will produce a mould fully rapid prototyped, or a hybrid of traditional machined and 3D printed is best.

The freedom of 3D printed sand core technology in permitting hybrid solutions mean that concept designs can be quickly realised from 3D CAD files.

With a build volume of 800 x 500 x 400mm parts can be printed in one piece, or stuck together to form larger moulds for sand casting. Molten metal is then poured into the mould (the sand can withstand temperatures of up to 1,700°C), left to harden, and the castings are then removed from the sand mould before being cleaned up.

G&W uses high heat strength systems, a phenol based binder with a silica/synthetic blended sand, which produces a core with up to 250 per cent higher hot strength compared to the more traditional 3D printed furan technology. This makes the cores suitable for the casting of both iron and steel, whilst also offering significant advantages in the stability of aluminium castings.

By using tool-less casting technologies G&W’s customers have almost unrestricted design and significant advantages over both lost wax and lost foam casting, giving the customer previously unfeasible geometry.

With the S-Print in operation over 100 hours a week, the technology that was brought in-house following some intensive research has moved from being a tool for specialist jobs to being a production workhorse.

G&W then verifies the parts using one of two CT scanners for aluminium parts, or a GOM laser scanner and a Romer laser arm for iron and steel parts.

Having the perfect parts first time is a must when producing low production volume parts for race machinery, or tier one and two automotive suppliers, so inspection forms a intensive part of the process, and can feed back into the 3D CAD data to reverse engineer any changes.

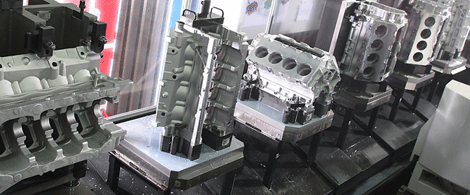

As well as casting, Grainger & Worrall also have the machining capabilities for finishing and fine tuning parts, such as these engine blocks

Three Pro Tips

In our 3D Printing For The Professional 2014 guide, Grainger & Worral facility manager Anthony Middleton gave us a run down of what they had learned by using the machine:

#1 Foundries not included

Having a sand printer on site has been a fantastic benefit to our productivity and reaction time to customers. However, this system is an indirect digital manufacture method.

Once we have produced the sand moulds, they still have to be poured with metal (aluminium, iron, steel etc.) to achieve your final metal part.

#2 Big parts, big space

The S-Print has an 800 x 500 x 400mm build area and can print this in a little over 10 hours (depending on layer thickness). This equates to over 500kg of sand being produced a day.

Typically, we can produce two tonnes of moulds and cores per week. That requires a lot of space for raw materials, cleaning and part storage.

We also split our setup into two areas; one for printing and one for post processing and storage.

#3 Big parts, bigger savings

Unlike most 3D printing technologies, the raw materials are relatively cheap.

Looking at a standard powder-based printer, the powder costs around £700 per 15kg. The S-Print sand (powder) costs £300 per tonne and any unbound sand can be reused.

Aside from our sand moulds we are starting to work with companies looking at other uses, such as large composite moulds (GRP and carbon fibre), art sculptures and building applications.

3D printed house bricks, closer than you think!

You can download our full 3D Printing For The Professional 2014 special guide here.