Toolkit3D Footwear Design Apps have been launched as a modular software suite for footwear professionals, giving them the tools to design and manufacture custom products faster and more precisely than ever before.

The three Toolkit3D applications — Insole, Midsole, and Design-to-Mold — each address a critical step in the footwear development process, from scan-to-print insoles to profile-driven midsoles and tooling-ready moulds.

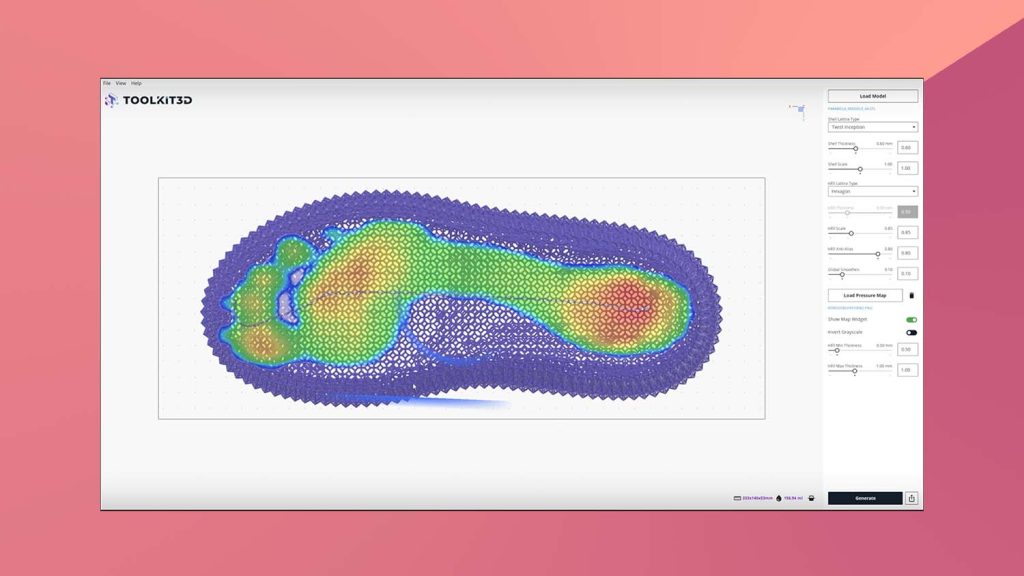

The Insole App allows for foot scans or existing models to be imported, generates a parametric base and adds functional features like embossing, lattice infill, rims, bases and labels. The results can be exported as STL files and users can prepare layouts for production with automated nesting.

Performance can be fine-tuned in the Midsole App, which offers adaptive or implicit lattices. Built for drop-in or traditionally assembled footwear, midsoles can be exported for prototyping or integrated directly with mould derivation.

Toolkit3D add the the Design-to-Mold App can derive complete three-part moulds (bottom stamper, left and right side rings) from midsole designs in minutes. Users can create midsoles from last profiles using SVG contours and apply textures and embossing from 2D images. This is compatible with CNC machining and additive manufacturing workflows.

“With the launch of these apps, we’re making advanced algorithmic design accessible and scalable,” said Toolkit3D CEO Edward Ponomarev. “Whether you’re a lab building orthotics, a brand innovating in performance footwear, or a manufacturer preparing for production, these tools put precision and speed at your fingertips.”

The Footwear Design Apps Suite is the latest product from Toolkit3D, which provides a range of algorithmic design software for custom manufacturing from orthotics to consumer applications, allowing users to turn scans and profiles into ready-to-produce designs at scale.