Siemens NX 2021, with its mature convergent modelling, plus new implicit and algorithmic modelling capabilities, is looking to support users intent on pushing boundaries from a single toolset, as Al Dean reports

Siemens NX, the engineering giant’s flagship product definition system, has undergone some interesting changes of late. For a start, the system has moved to a continuous update model, where more frequent updates are rolled out to users who choose to adopt that method of keeping their software current.

What’s interesting is that, unlike some newer systems that mandate such updates, the Siemens NX team recognises it has a mix of users. Some are keen to jump on any update. Some just aren’t. In response, it’s made the process optional. In other words, users can update as and when they (and their organisation) sees fit.

Second, the core underlying technology of Siemens NX 2021 has not just moved to synchronous technology, but is also now able to cope with a more diverse set of data than just the usual pure solids and surfaces. Specifically, mesh-like data can be brought in as a firstclass citizen, rather than an afterthought or something to be worked around.

This new technology, referred to as convergent modelling, has now reached the point where its goals are truly starting to be achieved. So let’s start with this, then take a look at some other recent updates.

Siemens NX 2021 – Convergent surface fitting

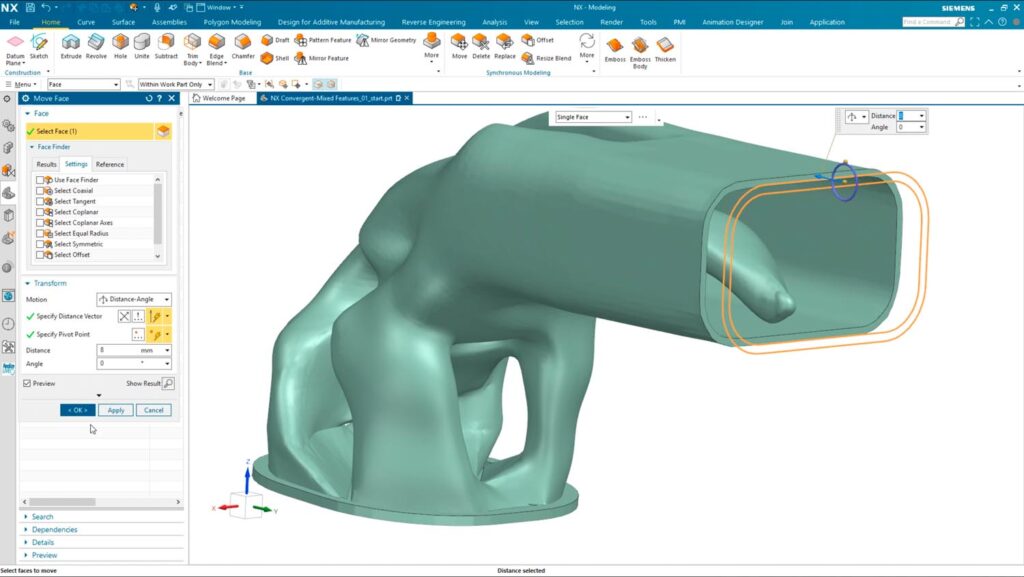

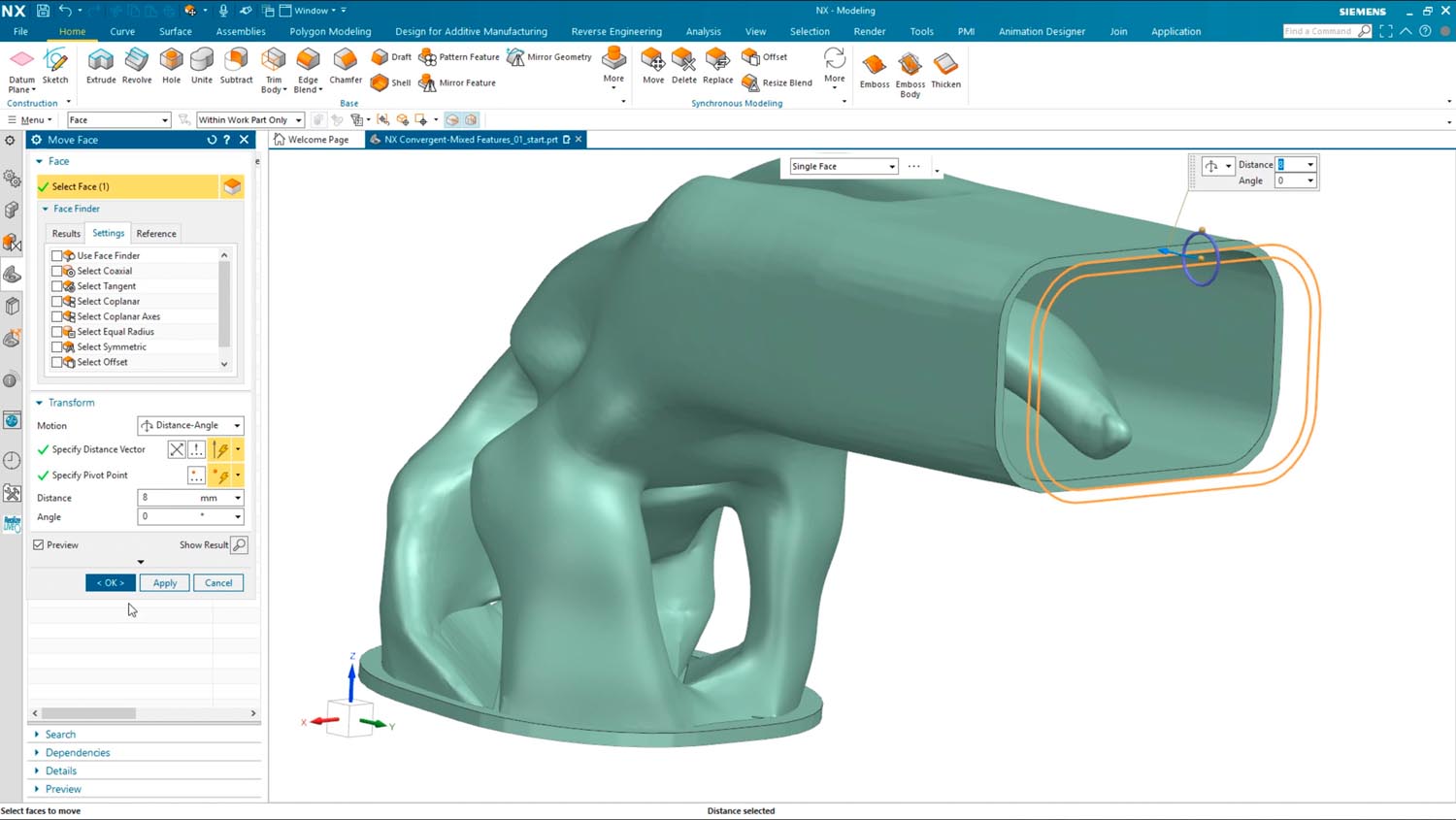

The last few releases of Siemens NX have seen convergent modelling advance from simply holding mesh data as part of the traditional part model to allowing features to be built up and to include mesh faces.

The system also supports operations that interact with both types of geometry at the same time, such as running a fillet or blend at the points where mesh and solid geometry intersect.

These tools have now been extended to allow quick replacement of mesh-faces with analytic geometry using a surface-fitting approach.

This is fundamental in solving the whole problem. It is now possible to have solids, surfaces and mesh data in a single part and have the type of geometry exactly where you need it. That makes the whole thing much more powerful.

Let me explain further. Now that these analytic faces can be defined on the mesh, they can be used just as you would surface or solid faces, whether that’s for easier editing, measuring to/from, assembly mating, machining or generating PMI data.

These new surface-fitting tools follow the same approach that many systems do, using the mesh to define an analytic face such as a plane, a hole or a cylinder. There’s no previous segmentation of the mesh requirement and you get feedback on the deviation between the mesh and your final surface.

There are also some interesting things going on under the hood once you combine these capabilities with the direct edits in Siemens NX 2021.

For example, if you grab a fitted face built onto a mesh and move it, the system will extend the mesh behind that move and allow you to make tweaks without all of the hassle that you might normally associate with adding, for example, machining stock to a mesh-based part.

Siemens NX – Algorithmic modelling

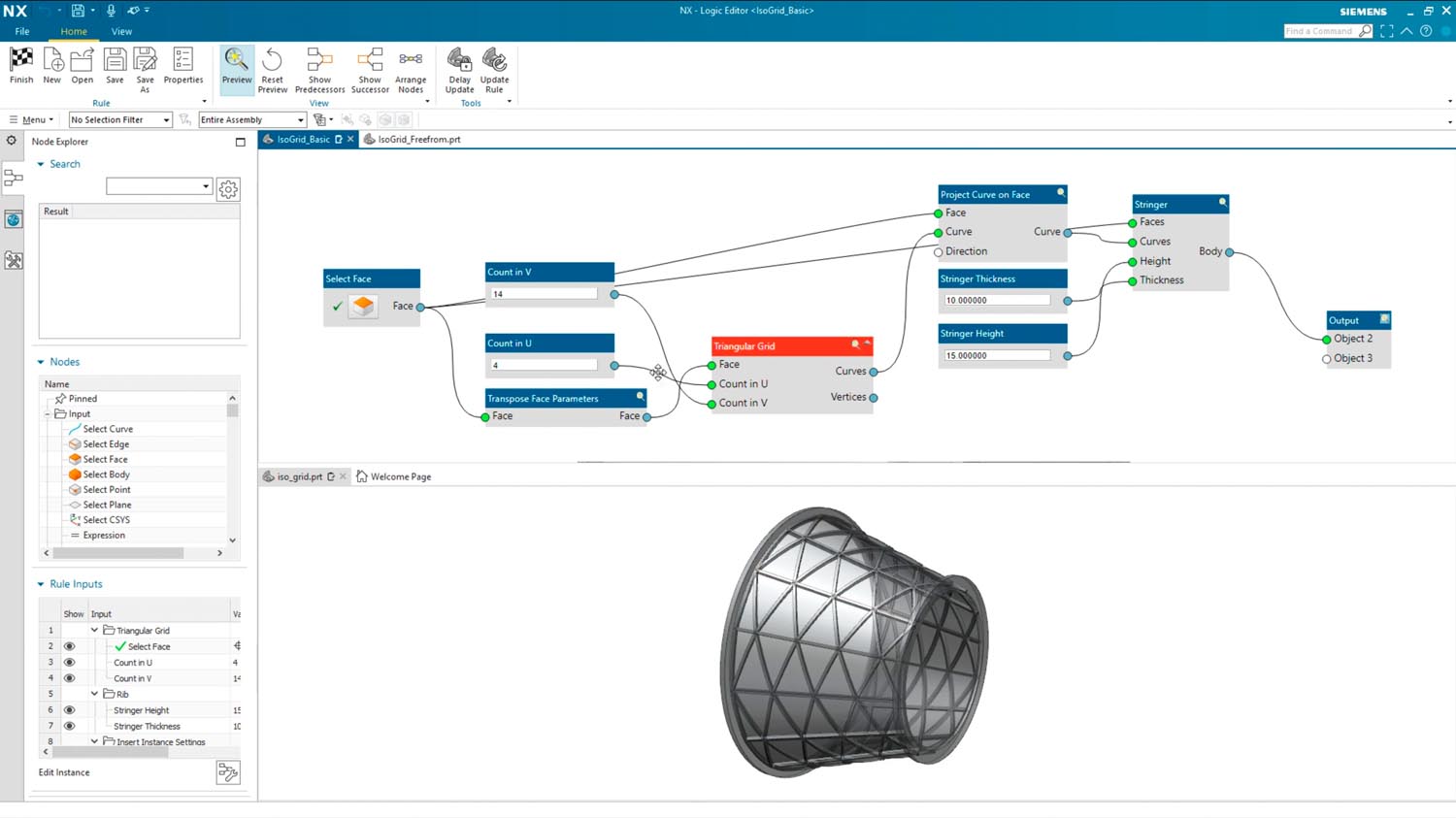

The next big addition to Siemens NX for this release cycle is algorithmic modelling, a response to how Siemens’ competition is addressing the definition of complex forms, particularly new-generation developers like nTopology.

When we talk about complex forms, we mean the types of forms that have gained exposure due to uptake of additive manufacturing, but that are by no means limited to those manufacturing processes. Whether that’s lattice in-fill for light weighting, gyroid in-fills for heat exchange or heat sinks, or the use of mathematically driven patterns and structures, the tools you use are common.

Within Siemens NX, these tools manifest themselves as a new node-based definition environment. The idea here is that you take your starting point, add in how each node processes the inputs and outputs, and pass them onto the next stage to achieve the desired end result.

If we take a look at Figure 1, you’ll see a geometric select (in this case, a face) selected as the first left-hand node. The system then creates a UV count for that face and applies a triangular grid to it with those UV controls.

That grid is then projected onto the face, ribs are built from those curves and then it’s output to display in the final node. This is a relatively simple set-up, but to create this type of structure manually would be a royal pain in the behind and would not be particularly intelligent.

With this new environment, a change made to the original geometry could be very quickly reapplied – or indeed, that process could be saved as a ‘rule’ and shared with other users. In this way, it can be applied to other forms from the NX Reuse Library.

On this subject, it’s key to note that only the authoring of these rules is a licenced activity – not for reuse.

Siemens NX 2021 & implicit modelling

Alongside the algorithmic modelling additions, another geometry creation method that has had its profile boosted by additive manufacturing is implicit modelling. The term refers to the process of defining a set of geometry (such as a hugely complex lattice, for example), using a set of implied commands and a graphical preview on screen.

That’s opposed to explicit modelling, which defines everything in hard geometry. In practice, this type of approach can be used for a lot of things, but it’s most commonly used to make the creation of super-complex lattice structures more efficient.

While NX has included some lattice forms for some time now, the 2021 release cycle brings on board one of most commonly used: Voronoi. This can be used in all manner of applications, from crumple zones and shock distribution to the medical field, to assist with osseointegration for bone implants.

Other new tools in Siemens NX 2021’s implicit modelling offering include the ability to have lattices defined in multibody parts (this would previously require something of a workaround) and to connect lattice structures to part bulk (such as a lattice in-fill connection to the walls of a heat exchanger).

There’s also the ability to smooth/blend lattice spar intersections to achieve a strong connection, though right now, there’s no ability to automatically smooth the connection between a lattice and part bulk, which would round things out nicely – pun absolutely intended.

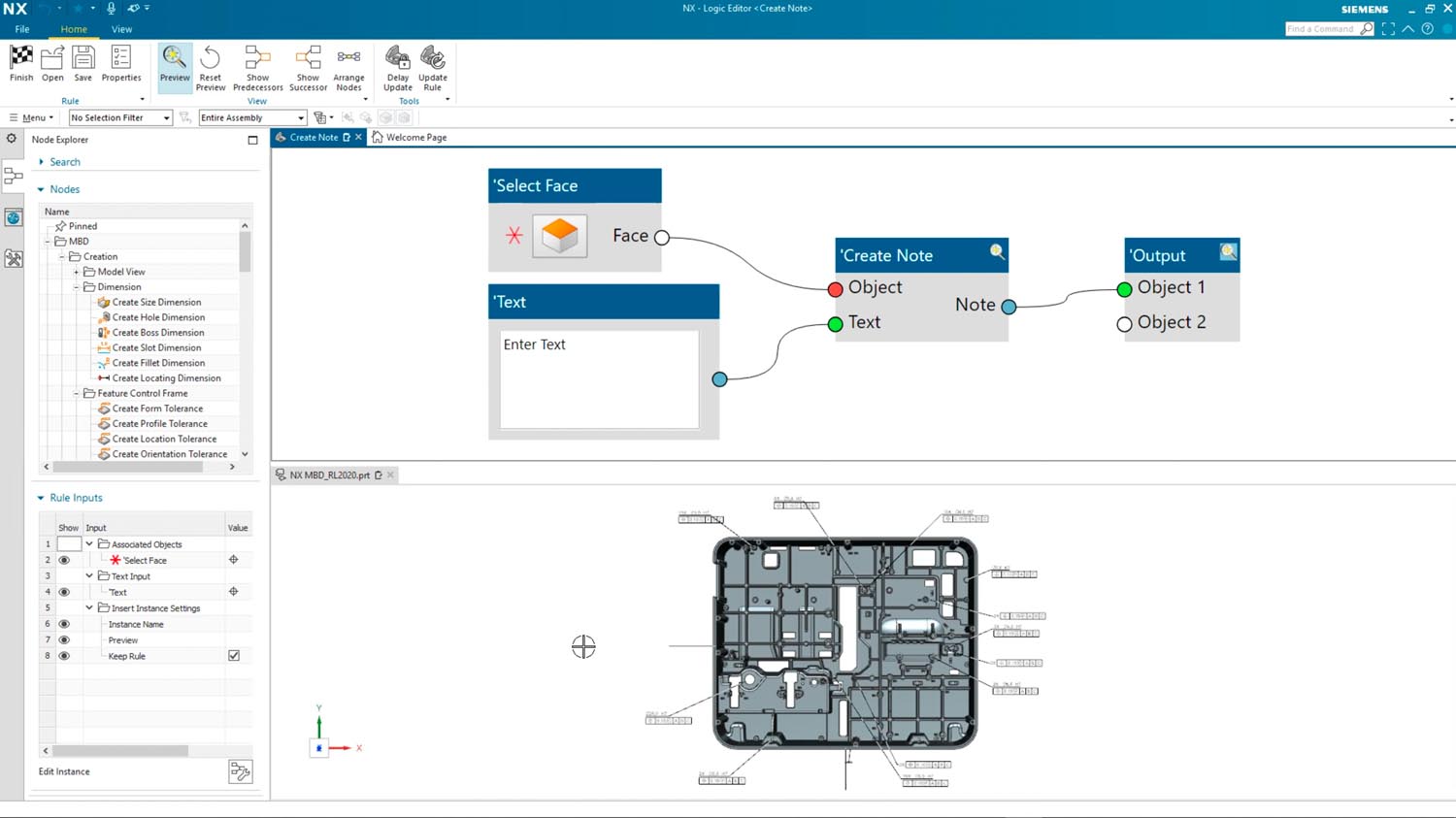

Model-based definition

The use of a 3D model as the host for all of the essential documentation associated with engineering drawings is not a new concept. Whether you refer to it as PMI, MBD, PPR, 3D annotation, it’s all essentially the same.

Rather than creating separate drawings that show curated orthographic views to store and display GD&T information, it’s stored instead on the 3D model using intelligent views of that model.

In other words, diverse dimensions, tolerances and annotations move from being static items on a drawing to dynamic data points. Select a datum on a drawing and the system can show you the referenced faces or features in a model, either as an orthographic view or in a rich 3D model. The potential is huge, if used sensibly and in a controlled manner.

The issues here are often less about the benefits (well-established within the industries most bullish on MBD) and more about the efforts required to create PMI in the first place. To address this, Siemens NX 2021 has a set of new tools to assist.

The first is a set of rules-definition tools that use a node-based interface similar to that used for algorithmic modelling. Here, they are used to capture how your company defines its dimension and tolerance information and how that PMI is applied to a model. Once created, these rules are then made available in the reuse lIbrary.

Alongside these tools to speed up creation, there are also a new set of validation tools to ensure that the PMI you create is compliant with both industry and company standards, whether they’re created using the automated tools, the rules-based approach or interactively/ manually. These validate each piece of PMI against both ISO and ASME standards, and not only highlights potential issues graphically, but also offers correction actions to fix them.

Other updates of note

Alongside the big-ticket updates in product design, there are a whole host of others that we don’t have room to cover in depth, but are worth mentioning. (There’s also a whole other review’s worth of manufacturing updates, too.)

One highlight is the wealth of new visualisation materials delivered with the system, almost 1,000 delivered with the latest release, as well as a brand-new appearance management toolset.

The idea here is that Siemens is building on its acquisition of Lightwork Design and its visualisation knowledge to make the creation and assignment of appearances more manageable.

Specifically, these features enable you to define visual appearances without having to open and edit individual parts. They also use a new material-specification feature within NX, which will make visual properties and material definition more consistent across the entire application.

Siemens NX 2021 – In conclusion

NX Is, as we all know, a mature beast of product design and engineering system. It runs the gamut of all of the common or garden modelling tools to the super-niche, within a niche, within a niche. It’s all there, if you have the need and the budget for it.

This release shows that there’s still room to grow, particularly when it comes to supporting new methodologies, new ideas and new manufacturing techniques.

But the maturation of convergent modelling, plus the introduction of implicit modelling and now algorithmic modelling, shows that Siemens NX 2021 is capable of supporting those users who are intent on pushing boundaries from a single toolset.

You won’t find its equal anywhere else on the market at present. If another vendor claims it can provide all this, you’ll probably find that it’s lying to you.

Yes, you could piece together a similar toolset from multiple providers – but from a single source? Not a chance. If you want to take a good, hard look at the current state of the art, you should definitely start here.

Yes, it’s perfectly true that Siemens NX has a steep learning curve. Yes, it’s a costly system for an organisation to adopt, manage and maintain – but at the same time, there’s still nothing else quite like it on the market today.