With the launch of nTop 5, the company has interoperability partners for its implicit modelling technology, including Autodesk, Hexagon, Materialise, Intact Solutions and Cloudfluid.

The partners have all built nTop interoperability into their software for a better end-to-end process between high-performance designs across simulation and manufacturing applications.

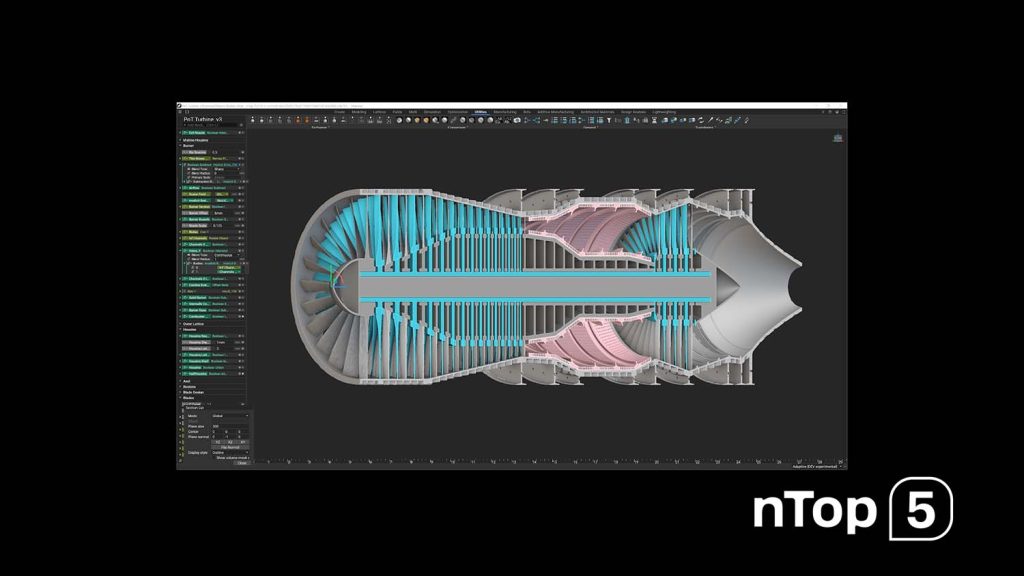

The update features what nTop describes as a powerful new kernel built from the ground-up, that it says enables greater precision and accelerates common design operations, saving engineering time. “It can take the most complex design challenges and deliver a stronger foundation for expanded modelling possibilities, faster slicing, meshing, and rendering operations, and even greater precision,” said a spokesperson.

Building on top of last year’s launch of nTop Core, a developer library for software partners that lets applications natively read and query information within nTop models, the latest expansion includes mechanical simulation, CFD and build preparation tools with the five new integration partners:

Materialise Magics – the widely-used build preparation software for 3D printing can now massively reduce build preparation and slicing times of high-performance parts through the direct import of nTop designs into Magics.

Once inside Magics, users can prepare and validate the build parameters, and generate optimised toolpaths. This integration will be available in early access to select companies in Q3 of 2024 and with a broader release in 2025.

Autodesk Fusion – Implicit interoperability with Autodesk Fusion lets nTop users perform a variety of downstream tasks in Fusion and more easily complete the design-to-manufacturing workflow. nTop users can effortlessly transition their designs to Autodesk’s comprehensive CAD/CAM tools using the nTop Connector add-in for Fusion.

Once inside Fusion, users can interrogate a model, integrate implicit models into larger product assemblies, and prepare models for production with the advanced manufacturing toolsets. The nTop Connector is available today in the Fusion App Store, available to all Fusion and nTop users at no additional cost.

Hexagon scSTREAM – Advancements in the design of heat sinks, chill plates, manifolds, and filters require accurate and rapid CFD analysis. To meet this need, nTop has partnered with Hexagon to integrate data from nTop models into Cradle CFD scSTREAM, a CFD application created specifically for thermal management of large and complex assemblies.

scSTREAM reduces manual processes by 80% and offers 5-10x faster calculation speeds. The combination of scSTREAM and nTop Core relies on a direct data transfer technology for implicit models that eliminates the need to simplify or compromise users’ design integrity to achieve fast, accurate results.

Intact.Simulation – Intact.Simulation provides mechanical simulation capabilities that remove the meshing bottleneck. With Intact.Simulation, designs can be loaded directly from nTop without any loss in fidelity and perform linear elastic, modal, and thermal analysis solved directly on the implicit model.

This allows for faster iterations and the ability to analyse designs containing lattices and other highly complex geometries that were simply impractical in traditional FEA tools.

Cloudfluid – To address growing interest in advanced design strategies that improve the performance of heat exchangers and manifolds, cloudfluid provides a solution for performing CFD analysis on products containing complex geometric features. With this integration, cloudfluid can import .implicit models from nTop, set up the simulation on the model without meshing, and compute the results quickly using cloud-based GPU processing – powering a significantly faster heat exchanger design workflow.

“For over 10 years, our mission at nTop has been to help high-performance engineering teams design beyond the limits of traditional software,” said nTop CEO Bradley Rothenberg. “Our customers have amazed us with the products they’ve developed in nTop – from super-efficient heat exchangers, to ultra-lightweight components for spaceflight and aeronautics, to patient-matched implants that enhance bone fusion, and more forgiving, high-performance golf clubs.

“nTop 5 is a leap forward in implicit modelling technology and the integration of our new ecosystem partners will expand what our customers will be able to create while streamlining workflows using the tools they know and rely on.”

Cobra Golf chips in with Limit3D irons benefitting from nTop modelling