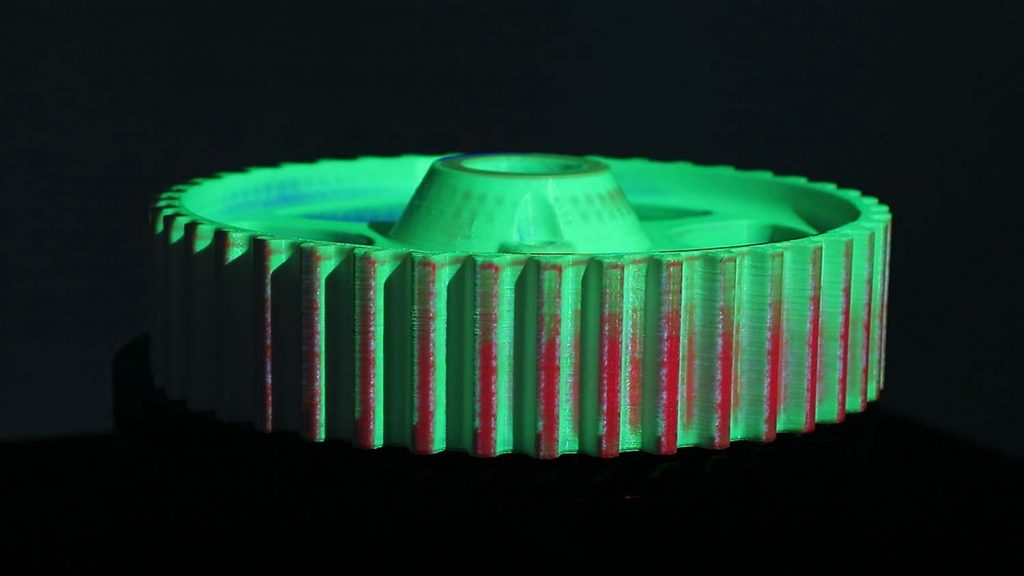

Smarttech3D has released the Micron3D Green 3D scanner, capable of directly projecting a colour map of CAD/Part deviation onto the object.

Smarttech states that the Micron3D Green combines a completely new system and software, offering advanced functions for quality control.

Smarttech3D suggests that the projection functionality works via the included measurement software module.

The software allows users to import the CAD file and generate a colour map of deviations, allowing the user to easily locate any deviations directly on the real object, comparing scans with the 3D model.

Users are able to generate personalised reports in PDF with annotations, including acceptable tolerances, and share the results with end-customers.

The Micron3D Green uses structured green LED light with wavelength of 520 nm to reduce the impact of external lighting changes, combined with stereo 9MP cameras, and a claimed 2.5 seconds for each measurement sequence.

“By incorporating omnidirectional fringes projection, the new scanner is capturing precise information about the geometries with automatic edge sharpness representation and noise reduction,” said a company spokesperson.

“This solution allows to significantly reduce the time of measurement and creation of a high quality and high resolution triangle mesh of the scanned objects.”

The 3D scanner is built from a sealed, full carbon fibre housing, with HEPA filters to reduce the impact of temperature changing, and dust.

Furthermore, measurements can be automated, which can enable a high volume of parts to be inspected under stable metrological conditions.